Over-voltages and current spikes must be avoided in many areas of electronics; numerous laws and regulations in the various destination countries specify product safety in explicit terms.

The corresponding over-voltage protection components can also lower the failure rate as well as maintenance and repair costs. Application article published by Rutronik explains the key protection principles and the different component features on Yageo portfolio.

Static discharges and over-voltages (transients) can destroy circuits. If a surge voltage that exceeds the permissible operating voltage of an IC is applied to a circuit, it can permanently damage the IC.

To clamp these damaging transients, that is, to deflect them to ground potential, thereby protecting the IC, various components for overvoltage protection are available. These include MOVs (Metal Oxide Varistors) and TVS (Transient Voltage Suppressor) diodes, GDTs (Gas Discharge Tubes) or ESDs (Electrostatic Discharge Diodes).

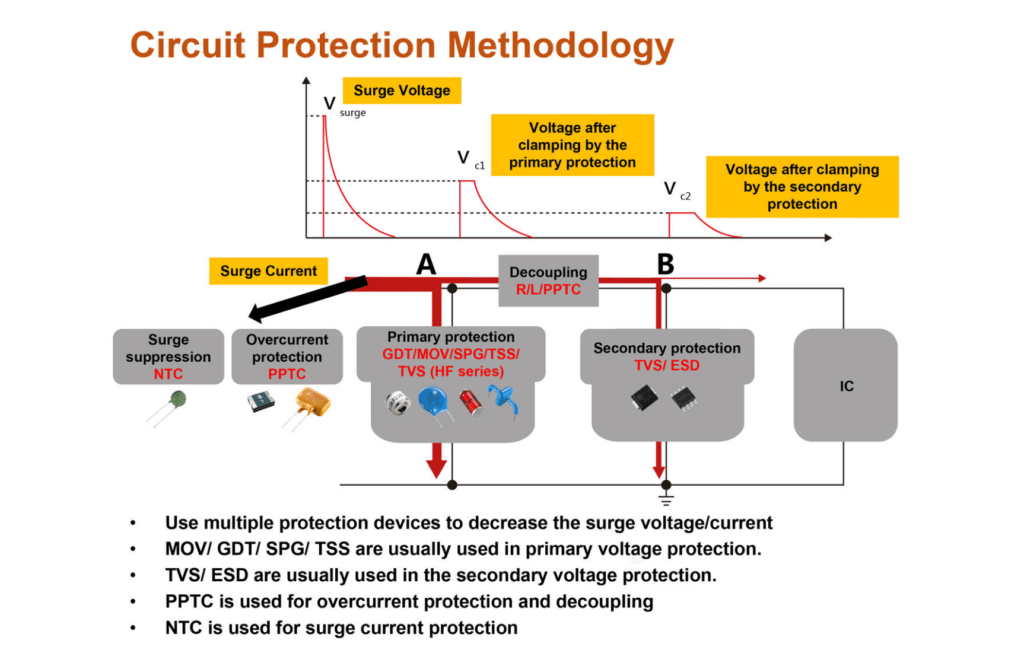

Figure 1 provides a schematic overview of the various types of protective equipment and levels for electronic circuits. The principle required here is the use of multiple protective elements to deflect transient overvoltages and overcurrents. Components such as MOV, GDT, SPG (Spark Gap Protectors) and TSS (Thyristor Surge Suppressors) serve as the primary form of protection against overvoltage.

TVS and ESD components provide the secondary protective effect. PPTCs (Polymeric Positive Temperature Coefficient Thermistors) act as overcurrent protection and as decouplers, while NTCs (Negative Temperature Coefficient Thermistors) are used in order to suppress overcurrents.

Varistors score highly thanks to their short response time

Due to their very short response time, varistors are used in numerous applications for clamping transient overvoltages of below 20 ns. The best-known of these are Metal Oxide Varistors (MOV). That is because they are capable of absorbing overvoltages – and significantly higher voltages than TVS diodes.

MOVs are manufactured primarily from zinc oxide. They offer a wide voltage range from 18 to 1800 V, and for surge currents of up to 70 kA, in some cases even more. The MOVs by Yageo are available with safety certification according to UL/TÜV/VDE(CSA/CQC) and for operating temperatures from -40 to +105°C and -40 to +125°C. Their Ipp values range from several hundred amperes up to several dozen kiloamperes, and they have pulse forms of 8/20 μs. In this case, the VBR value is bidirectional and symmetric.

For this reason, these MOVs are widely used in AC current supplies, signal lines and circuit breakers, LED drivers or smart-metering systems. Rotor diameters of 5 to 53 mm enable the simple selection of the correct component for each of these applications. Yageo also offers TMOV varistors as a special solution. By combining a Metal Oxide Varistor and an NTC, they can effectively limit both currents as well as overvoltages.

The disadvantage of MOVs is that, unlike TVS diodes, they can age. This means that they only have a limited-service life, depending on the transients that they absorb. To mitigate this effect, they are typically used in series with GDTs or SPGs.

TVS diodes guarantee rapid unidirectional or bidirectional blocking

TVS diodes, also referred to as suppressor diodes, TVPs (Transient Voltage Protectors), ABDs (Avalanche Breakdown Diodes) or BODs (Break-Over Diodes), can clamp overvoltage peaks within a safe range of picoseconds and restrict them to a safe value to protect the circuit from damage. These are the components with the best clamping behavior among Image 3: The operating principle of a TVS diode parallel to the load use of protection components in key applications (source: Yageo) the protective diodes and are connected parallel to the load to be protected (Figure 2).

The primary advantages of TVS diodes are their short response time and low capacitance and their ability to provide unidirectional and bidirectional protection. As such, they are ideally suited for DC current supplies, security and surveillance systems as well as in the telecoms and automotive sectors.

TVS diodes by Yageo are supplied with UL safety certification. They are also available with automotive-grade qualification (AEC-Q101) and stand out by virtue of their low dynamic internal resistance and rapid response characteristics. They are available for a Pppm of 200 to 30,000 W for 10/1000-μs pulse forms and Ipp values of 6/10/1620 kA in 8/20-μs pulses. Vrem is specified as 3.3 to 600 V (or higher). Enclosure shapes SMAJ, SMBJ, SMCJ, DO-41, DO-15, DO-201 and others are available. Figure 3. shows a comparison of the protective properties of MOVs and TVS components.

The growth market of electric mobility

Although the TVS diodes are relatively recent additions to the Yageo portfolio, the supplier has drawn up a dedicated road map for TVS products with a focus on automotive, high power and high surge applications. By further expanding the road map and adding new enclosure designs for future applications, Yageo is pursuing the stated objective of capturing further market share in the protection component segment, above all in the growth market of electric mobility.

Due to the stricter CO2 limits that will take effect starting in 2020, suppliers are under pressure to reduce the CO2 emissions of their vehicle fleet substantially. As a result, the development of electric vehicles has picked up speed noticeably and is set to accelerate further. Protection against overvoltage is essential both for electric vehicles themselves as well as in the area of the charging infrastructure. This is where TVS diodes with their specific characteristics are particularly suitable for use as circuit protection components.

Additional protection components

TVS arrays are offered as electric-discharge protection devices with operating voltages in accordance with the applicable values of the IC supply voltage (2.8 to 36 V). They are supplied with low capacitance (below 1 pF) for high-speed data interfaces such as HDMI and USB 3.0 in various compact enclosure shapes.

SPGs (Spark Gap Protectors) are available with UL certification for Ipp values between 300 and 3000 A for 8/29-μs impulses as well as a DC spark-over voltage from 140 up to 5000 V. They offer an isolation resistance of >100 MΩ combined with a low aging effect and are not polarized.

GDTs (Gas Discharge Tubes), likewise with UL/VDE certification, are available for Ipp values between 500 and 100 kA (8/20-µs impulse) and DC spark-over between 75 and 6000 V (impulse spark-over up to 7800 V). These GTDs offer isolation resistance of around 1 GΩ. Typical applications are in coaxial cables and Ethernet connections.

TSS components (Thyristor Surges Suppressors) for telecoms and surveillance systems, smart meters, etc. offer an Ipp of several hundred amperes (8/20-µs impulse) and a low leak current of between 1 and 5 µA at a precise spark-over voltage (VDRM: 6 to 620 V).

PPTCs (Polymeric Positive Temperature Coefficient Thermistors) are suitable for the same applications as TSS. Under normal operating conditions, they have a very low resistance and have no effect on the circuit to be protected. Consequently, they are operated in series to the circuit. The response speed of several milliseconds is quite low, and is proportional to the current value. Ihold is between 30 mA and 14 A, and Vmax can be 5 to 600 V.

NTCs (Negative Temperature Coefficient Thermistors) with their exceptional, long-term stable thermal cycle behavior are ideal for power supplies (UPS) and power adapters. They are supplied with diameters of between 5 and 25 mm (5D to 25D).

Selection Guide

In summary, suggested selection decision guideline for protective components is provided in figure 4. Table in figure 5. is showing use of protection components in applications driven by their typical features and requirements.