This article explores, the evolution in passive component technology demanded by modern and emerging automotive electrical systems.

It discusses the trends, recent advances in materials science, the demands imposed by wide bandgap semiconductors, evolving validation protocols, system-level design trends, and future technological directions, with emphasis on practical implementation, reliability, and next-generation architectures.

Key Takeaways

- The article discusses the evolution of passive component technology driven by modern automotive electrical systems.

- It highlights the impact of wide bandgap semiconductors on passive components, demanding advanced performance and reliability.

- Material innovations lead to superior capacitors and resistors, enhancing efficiency and thermal stability in vehicles.

- Additionally, the piece outlines the need for advanced validation criteria to ensure component durability under harsh automotive conditions.

- Overall, passive components are now essential for vehicle safety, reliability, and efficiency in electrified platforms.

1. Introduction

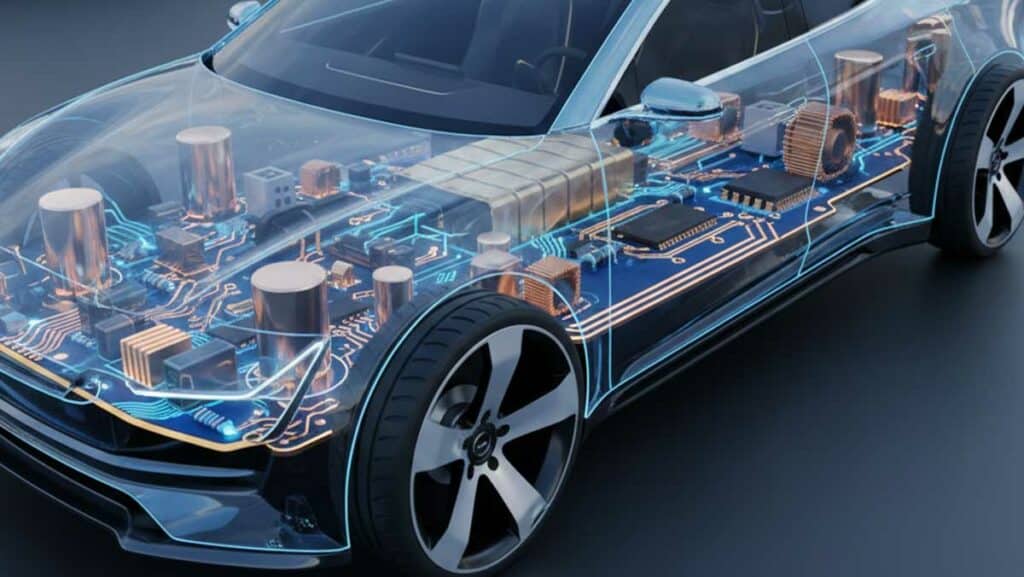

The rapid progress of automotive electrification is fundamentally transforming the field of vehicle electronics. Driven by rising operating voltages, dramatic increases in electrical energy demand, and growing functional integration, passive components must now deliver uncompromising power integrity, robust EMI control, advanced thermal management, and exceptional reliability over a vehicle’s service life.

Background: Evolution of Automotive Electrical Systems

Historically, the automotive electrical system centered around a straightforward 12V electrical bus, which proved satisfactory for decades of mechanical and electro-mechanical vehicles. As automotive design rapidly advanced through increasing deployment of electronic control units for everything from powertrain management to safety and comfort features, the current-carrying capacity of the 12V architecture reached its physical and practical limits. The introduction of electrically actuated systems—such as power steering, HVAC compressors, turbochargers, adaptive suspensions, and electrically operated brakes—resulted in surges of both peak and average current requirements that the legacy system could no longer support without impractical increases in alternator size and wire gauge.

The introduction of hybrid and electric propulsion systems spurred a further evolution. Modern vehicle designs now feature a diversity of voltage domains: the well-established 12V rail coexists with supplementary 48V systems for high-load subsystems, and with ever-more prevalent 400V to 800V high-voltage buses powering battery electric vehicles (BEVs) and plug-in hybrids. These high-voltage platforms support ultra-fast charging, boost powertrain efficiency, and minimize resistive losses. Yet, they simultaneously introduce significant complexities, including a need for extensive DC-DC conversion, far more switching events, and the creation of challenging electromagnetic interference (EMI) profiles throughout the electrical network.

| Domain | Main Application | Typical Voltage | Key Challenges |

|---|---|---|---|

| Legacy Systems | Lighting, controls, infotainment | 12V | Limited current, rising loads |

| Supplementary/Subsystem | eTurbo, ePower steering, HVAC | 48V | EMI, ripple, integration |

| Traction/Charging | BEV, Plug-in Hybrid | 400V–800V | Safety, insulation, fast-charging |

2. Material Science and Innovations in Passive Components

Capacitors: Downsizing, Higher Frequency, Lower ESR and Robustness

Modern automotive electronics require capacitors, inductors, resistors, and other passive components that far exceed the reliability, stability, and performance parameters of their predecessors. The rise of hybrid and polymer-based aluminum capacitors and polymer tantalum capacitors offers a compelling alternative to traditional electrolytic capacitors through enhanced ripple-current handling, greatly reduced ESR, and its superior thermal stability. These traits are essential for filter capacitors in high-frequency power conversion and fast-switching topologies.

Multi-layer ceramic capacitors (MLCCs)—particularly those employing Class I dielectrics such as C0G and U2J—provide outstanding frequency and temperature stability with the lowest ESR, making them indispensable for RF applications, high-frequency filtering, and decoupling tasks. Class II dielectrics (X7R/X8R) enable extremely compact high-capacitance solutions, which, especially when equipped with flexible terminations, demonstrate remarkable resilience against mechanical vibration and thermal cycling. For high-voltage, high-ripple, and severe cycling environments such as those found in traction inverters, polypropylene film capacitors offer low loss and customized geometric forms, sustaining hundreds of amps of ripple current without degradation.

| Type | Key Feature | Voltage Rating | Main Application |

|---|---|---|---|

| Aluminum Electrolytic | Low Cost | Up to 400V | General Filtering |

| Polymer/Hybrid Aluminum | Low ESR, High Ripple, Thermal Stability | Up to 100V | Converters, Fast Switching |

| Polymer Tantalum | Low ESR, High Energy Density | Up to 75/125V | Converters, Fast Switching |

| MLCC (C0G/X7R/U2J) | Stable Capacitance, Vibration Resistant | Up to 1kV | Signal, EMI, Decoupling |

| Film Capacitor (Polypropylene) | High Voltage, Low Loss | 100V–1200V | DC-Link, Traction Inverter |

Resistors: Precision, Stability, and Circuit Protection

Automotive resistors have evolved beyond simple current-limiting components to serve roles in precision sensing, EMI suppression, and circuit protection. Anti-surge and pulse-resistant resistors are engineered to absorb brief, high-energy transients—vital for protecting sensitive electronics during fault events such as load dumps, short circuits, or switching noise intrusions. These resistors use specialized materials and robust terminations to maintain integrity across thousands of surge cycles, often validated according to ISO 7637 pulse immunity standards and stringent OEM requirements.

Precision current-sense resistors, frequently manufactured from nickel-chromium alloys or newly developed metal foils, deliver extremely tight tolerance and minimal temperature coefficient, ensuring reliable measurement for battery management, power distribution, and diagnostics. Their wide range of resistance values and form factors allows integration directly onto power modules or embedded within bus bars, enabling real-time monitoring and early warning for overcurrent, thermal overload, or system abuse.

High-voltage thick-film resistors are another innovation, designed to withstand elevated voltages encountered in traction or battery systems without arcing or dielectric breakdown. These products often incorporate glass or ceramic substrates and specialized resistive compositions to maintain insulation and safety margins, even in compact SMD footprints.

| Type | Main Benefit | Typical Application | Key Feature |

|---|---|---|---|

| Anti-Surge, Pulse | Surge Withstanding | Fault, Load Dump Protection | ISO 7637, AEC-Q200 Qualified |

| Precision (Current Sense) | Tight Tolerance, Low TCR | BMS, Power Monitoring | Integrated, Surface Mountable |

| Thick-Film, High Voltage | Voltage Isolation | DC-Link, HV battery | Ceramic/Glass Substrate |

Inductors and Chokes: Filtering, Energy Storage, and EMI Suppression

The demands on inductors and chokes have grown in lockstep with the evolution of automotive electrification. Modern power electronics rely on inductors for energy storage, power regulation, and, increasingly, for filtering high-frequency noise created by fast-switching wide bandgap semiconductors. Metal-composite inductors and nanocrystalline cored devices represent cutting-edge solutions, delivering high efficiency, broad bandwidth, and low DC resistance to minimize losses and maintain performance in compact modules. Their soft saturation characteristics allow operation in demanding current environments without catastrophic failure—a crucial trait for both primary power conversion and auxiliary circuits.

Automotive inductors must also address stringent thermal management demands. Integrated designs combine the magnetic element with heat sinking structures, often utilizing direct-contact cooling with chassis or cold plate, or embedding within power module substrates for optimal thermal conductivity. Advanced modeling and simulation are used to predict saturation limits, self-heating, and EMI suppression efficacy across wide temperature and load profiles.

Common-mode chokes are increasingly deployed within signal and power domains to comply with EMI emissions and immunity regulations such as CISPR 25. These chokes, composed of innovative core materials and precision winding techniques, are tailored to attenuate both conducted and radiated noise, particularly in high-current applications like electric steering or inverter output. Their design is often application-specific, tuned for the current, voltage, and mechanical environment of the end system, and extensively validated for reliability during vibration, humidity, and temperature cycling.

| Type | Main Function | Special Feature | Typical Use |

|---|---|---|---|

| Metal Composite Inductor | Energy Storage, Filtering | Soft Saturation, Low DCR | DC-DC Converters, HV Traction |

| Nanocrystalline Inductor | Broad EMI Filtering | High-Frequency Suppression | Onboard Charger, MCU Filters |

| Common-Mode Choke | Noise Attenuation | High Current Capability | EV Drive Outputs, Steering |

| Ferrite Bead/Chip | Signal Integrity | Miniaturized SMD | Infotainment, ADAS Sensors |

In summary today’s capacitors, resistors and inductors are far more than passive participants; they serve as key enablers of safety, precision, and efficiency in the electrified automotive ecosystem. Their development and qualification leverage the latest material science, simulation, and reliability standards, ensuring compatibility with the harsh realities and rapid innovation cycles of modern automotive design.

3. Wide Bandgap Semiconductors: Impact on Passives

The introduction of wide bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) has fundamentally changed the requirements and expectations placed upon passive components. Wide bandgap devices can operate at voltages and switching speeds far beyond what traditional silicon devices could support, translating into increased power densities and unprecedented performance gains for traction, charging, and auxiliary electric subsystems. However, this also means that passive components must endure much sharper voltage transitions (dv/dt), higher ripple currents, and more severe thermal cycles.

| Feature | Silicon | SiC/GaN |

|---|---|---|

| Max Switching Frequency | 30–50kHz | 100kHz–1MHz+ |

| dv/dt (V/ns) | 0.01–0.1 | 1–10 |

| Thermal Conductivity | 150 W/m·K | 360–490 W/m·K |

| Typical System Voltage | 400V | 800V+ |

4. Advanced Validation and Reliability Demands

Automotive standards such as AEC-Q200 have served as the foundation for passive component qualification for many years. Nevertheless, the accelerated pace of electrification has pushed requirements well beyond these traditional certifications. Today’s automotive passives must survive aggressive thermal cycling over wide temperature ranges, extended high-humidity exposures, continuous vibration at high g-forces, and extended lifetime stress even when installed in exposed under-hood locations.

| Criterion | Standard Requirement | Advanced Need |

|---|---|---|

| Vibration | ~10g, 2h/axis | 20–40g, 20h/axis, custom OEM cycles |

| Thermal Cycling | -40°C to +125°C, 1000 cycles | -55°C to +150°C, 3000 cycles, rapid ramp |

| Humidity | 40°C @ 93% RH, 96h | 60°C @ 95% RH, weeks/months exposure |

| Lifetime Expectancy | 10 years | 15–20 years, 0 ppm critical target |

5. Architecting the Electrified Powertrain for Fast Charging

The arrival of 400V and especially 800V vehicle architectures presents a dual-edged challenge. As the system voltage doubles, so does the electrical and dielectric stress borne by every component. Passive devices must be engineered with much tighter creepage and clearance tolerances, enhanced insulation technologies, and robust packaging methods to withstand these higher voltages. At the same time, rapid charge and discharge cycles introduce severe, repeated temperature swings, often in the absence of easy avenues for heat dissipation.

| Parameter | 400V System | 800V System |

|---|---|---|

| Rated Voltage | ~450V | ~900V |

| Ripple Current Handling | 170–250A | 350–500A |

| Lifespan Simulation | 10 years, 500 rapid cycles | 15 years, 2000 rapid cycles |

6. Pushing Passives to Their Limits: Miniaturization, Integration and Functional Trends

Relentless miniaturization pressures now push all passive devices toward smaller surface-mount profiles while also demanding integrated features such as enhanced thermal pathways, electromagnetic shields, and networked arrays of multiple function devices. Smart embedded passives—integrating capacitors, inductors, and ESD suppressors within a single substrate—are becoming increasingly attractive for space and reliability reasons.

These advances must be coupled with solutions that specifically address the harshest environmental exposures in automotive design: humidity, thermal cycling, corrosion, and mechanical fatigue. Passives destined for exterior, powertrain, or direct drive installations must comply with not only AEC-Q200 but also additional standards such as ISO 16750 and LV 123 for full-vehicle durability. Ultimately, future functional safety standards and the scaling-up of predictive diagnostic systems will require that passive components present predictable—sometimes even self-monitoring—aging signatures, especially for mission-critical steering, braking, or ADAS modules.

| Feature | Benefit | Implementation Example |

|---|---|---|

| Flexible SMD Terminations | Shock/vibration resistance | MLCCs for steering and braking modules |

| Thermal Path Integration | Improved cooling, longer life | Liquid-cooled inductors in inverters |

| Self-Monitoring Feedback | Predictive maintenance, safety | Status-enabled resistors in ADAS |

7. Case Studies and Real-World Examples

In a state-of-the-art steering module for battery electric vehicles, a specially designed common-mode choke is combined with pulse-stable resistors and arrays of MLCCs with flexible terminations. This enables the system to survive extremely harsh vibration environments, up to 20 times the levels stipulated in traditional AEC-Q200 standards, thereby dramatically extending reliability in the field.

A fast-charge traction inverter for an 800V system might deploy a custom polypropylene film capacitor DC-link, electrically matched with an active or passive balance network, and paired with liquid-cooled or chassis-coupled inductors. This architecture is validated using a 15-year lifetime simulation to ensure its ability to support repeated fast-charging cycles throughout the vehicle’s operation.

Similarly, an ADAS sensor fusion module designed for continuous operation in complex, EMI-rich environments leverages broadband suppression networks, vibration-rated MLCCs, and advanced pulse-resistant resistors. These are cross-tested under extended standards such as ISO 16750 to verify real-world signal integrity and functional safety requirements far beyond previous component generations.

8. Conclusion

The electrification of the powertrain and the digital transformation of automotive platforms are revolutionizing not only the world of advanced electronics but fundamentally reshaping material science, engineering, and system integration for passive components.

As new materials, simulation methods, and smart integration strategies become the standard, the role of passives shifts from silent background players to key enablers of system safety, reliability, and efficiency.

To match the sophisticated demands of future digitally connected and electrified vehicles, passive components must be engineered as rigorously as the microprocessors and wide bandgap semiconductors they support—ensuring both performance and robust operation throughout the harsh real-world conditions of tomorrow’s mobility.

FAQ About Passive Components in Automotive Systems

The increase in onboard electronics, electrification of subsystems, demand for rapid charging, and enhanced efficiency are pushing automotive electrical systems from the traditional 12V rail to new 48V, 400V, and 800V architectures. These changes support advanced safety, power, and data features in next-generation vehicles.

Wide bandgap semiconductors such as SiC and GaN enable much higher operating voltages and faster switching speeds, increasing thermal stress, ripple current, and EMI exposure for passive components. This necessitates advanced material science and optimized design for capacitors, resistors, and inductors.

Capacitors (MLCC, film, polymer), precision resistors (current sense, anti-surge), inductors (metal-composite, nanocrystalline), and common-mode chokes are essential for power integrity, filtering, EMI suppression, and safety in electrified automotive architectures.

Modern vehicles require components to survive intense thermal cycling, vibration, humidity, high-voltage stress, and 15–20 year lifespans. Standards like AEC-Q200 are frequently exceeded, and new OEM-driven validation protocols ensure passives perform safely in harsh, real-world scenarios.

Miniaturization leads to smaller SMD components with embedded features for thermal management, EMI shielding, and integration into smart modules, crucial for saving space in vehicle designs while maintaining reliability.

How to Select and Validate Passive Components for Automotive Electrification

- Analyze Application Voltage Domains

Begin by identifying the voltage requirements for each subsystem (12V, 48V, 400V, 800V) and the expected variations during normal operation and fault conditions.

- Determine Environmental and Reliability Needs

Assess the expected thermal cycling range, exposure to vibration, humidity, and planned vehicle lifespan. Select components rated for or exceeding standards like AEC-Q200, ISO 16750, or LV 123.

- Specify Passive Component Types

Choose appropriate capacitors (MLCC, Polymer, Film) for filtering and energy storage; precision resistors for current sensing and protection; inductors and chokes for noise suppression and regulation. Match material science to demands (e.g., soft saturation cores for inductors).

- Model and Simulate Electromagnetic Behavior

Use advanced simulation tools to predict ripple effects, EMI propagation, thermal characteristics, and layout-based parasitics for each passive component.

- Evaluate Lifetime at Relevant Environment

Validate selected parts under worst-case scenarios: extended vibration tests, rapid thermal cycling, surge and pulse events, and continuous operation at rated voltages and currents.

- Integrate Into Vehicle Platform for Real-World Validation

Finalize with in-platform testing, ensuring signal integrity, robust EMI mitigation, safe cooling, and integration with smart diagnostic systems for predictive maintenance.