ESPOO, Finland, Picosun Group, global provider of leading AGILE ALD® (Atomic Layer Deposition) thin film coating solutions, reports record performance of silicon-integrated, three-dimensional deep trench microcapacitors manufactured using its ALD technology.

Increasing efficiency and performance demands of portable and wearable electronics, along with their shrinking size in accordance with the Moore’s law, set new challenges to the power management of these devices as well. A solution is further integration of the devices’ key components into so-called SiP (systems-in-package) or SoC (systems-on-chip) architectures, where everything, including the energy storage such as batteries or capacitors, is packed close to each other into one compact, microscale-miniaturized assembly. This calls for novel techniques to increase the performance and shrink the size of the energy storage unit as well. Three-dimensional, high aspect ratio and large surface area deep trench microcapacitors where ultra-thin, alternating layers of conducting and insulating materials form the energy storing structure, provide a potential solution.

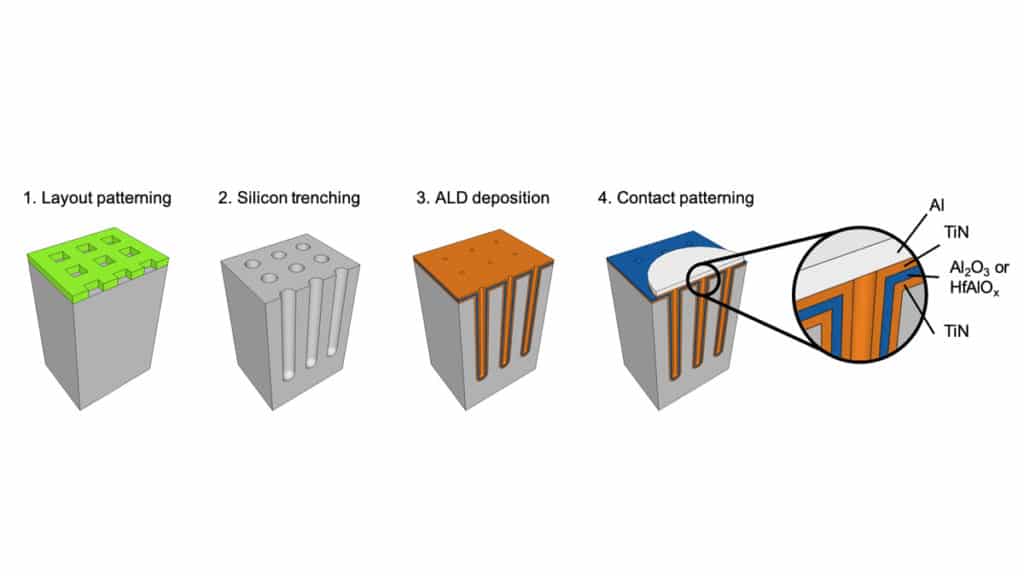

Featured Figure: Main technological steps of 3D microcapacitor fabrication. 1: patterning of a square lattice of holes on the silicon surface; 2: high aspect ratio trenching of silicon by electrochemical micromachining (ECM); 3: atomic layer deposition (ALD) of conformal metal-insulator-metal (MIM) stack; 4: aluminium deposition and contact patterning (*).

Picosun’s ALD technology has now realized unprecedented performance of these 3D microcapacitors. PICOSUN® ALD equipment were used to deposit film stacks of conductive TiN and insulating dielectric Al2O3 and HfAlO3 layers into high aspect ratio (up to 100) trenches etched into silicon. Up to 1 µF/mm2 areal capacitance was obtained, which is the new record for this capacitor type. Also power and energy densities, 566 W/cm2 and 1.7 µWh/cm2, were excellent and surpassing the values achieved with the most of the other capacitor technologies. The ALD microcapacitors showed also outstanding voltage and temperature stability, up to 16V and 100oC, over 100 hours continuous operation (*).

Figures above: b) SEM cross-section of an array of cylindrical trenches with a pitch of 4 μm, diameter of 2 μm and aspect ratio of 100, conformally coated with an ALD stack consisting of 40 nm of TiN, 40 nm of Al2O3, and 40 nm of TiN. Insets show a detail of the MIM stack at the top and bottom of a single trench; d) high-resolution TEM image of an MIM stack consisting of 40 nm of TiN, 40 nm of Al2O3, and 40 nm of TiN taken at the bottom of ALD-coated trenches with aspect ratio of 100; e) TEM-EDX elemental maps of Ti (yellow), N 14 (cyan), Al (red), and O (green) of the MIM stack in (d) (*).

These excellent performance indicators pave the way to industrial applications of this capacitor technology. This is further facilitated by ALD’s mature position in modern semiconductor industries, where the technology is already integrated into practically all advanced microchip component manufacturing lines.

“We exploited the room available on the bottom of silicon wafers, of which only a few micrometers of silicon are used for electronic components in integrated circuits, to fabricate silicon-integrated 3D microcapacitors with unprecedented areal capacitance. The electrochemical micromachining technology, developed at the University of Pisa over the past decade, enabled etching of high density trenches with aspect ratios up to 100 in silicon, a value otherwise not achievable with deep reactive ion etching. This posed the basis for increasing the areal capacitance of our 3D microcapacitors upon conformal coating with an ALD metal-insulator-metal stack,” says Prof. Giuseppe Barillaro, group leader at the Information Engineering Department of the University of Pisa, Italy.

“The suberb results achieved with our 3D silicon-integrated microcapacitors show again how imperative ALD technology is to modern microelectronics. We are happy that we can offer our unmatched expertise and decades of cumulative know-how in the field to develop novel solutions for the challenges the industry is facing, when the requirements for system performance and integration level increase inversely to the system size. The environmental aspect is also obvious, when smaller, more compact devices manufactured in the same line mean also smaller consumption of materials and energy,” says Juhana Kostamo, deputy CEO of Picosun Group.

Picosun provides the most advanced ALD thin film coating technology to enable the industrial leap into the future, with turn-key production solutions and unmatched expertise in the field. Today, PICOSUN® ALD equipment are in daily manufacturing use in numerous major industries around the world. Picosun is based in Finland, with subsidiaries in Germany, North America, Singapore, Taiwan, China and Japan, offices in India and France, and a world-wide sales and support network.

(*) “Three-dimensional silicon-integrated capacitor with unprecedented areal capacitance for on-chip energy storage”, Lucanos M. Strambinib,1, Alessandro Paghia,1, Stefano Mariania, Anjali Soodc, Jesse Kalliomäkic, Päivi Järvinenc, Fabrizio Toiad, Mario Scuratid, Marco Morellid, Alessio Lampertie, Giuseppe Barillaroa,b,∗, accepted for publication in Nano Energy, https://doi.org/10.1016/j.nanoen.2019.104281.

a Dipartimento di Ingegneria dell’Informazione, Università di Pisa, via G. Caruso 16, 57122, Pisa, Italy

b Istituto di Elettronica e di Ingegneria

dell’Informazione e delle Telecomunicazioni, Consiglio nazionale delle

Ricerche, via G. Caruso 16, 57122, Pisa, Italy

c Picosun Oy, Tietotie 3, Espoo, FI-02150, Finland

d ST Microelectronics, via Olivetti 1, Agrate Brianza, Italy

e IMM-CNR, Unit of Agrate Brianza, Via C. Olivetti 2, 20864, Agrate Brianza, MB, Italy

(Funding from the ECSEL Joint Undertaking through the R2POWER300 project, grant no. 653933)