A new pilot study from the Digital Cellulose Center on a greentech power paper shows promise for high-capacity storage of renewable energy. The electronic paper is completely made of organic material and the first testing’s show that the energy storage capacity is as efficient as conventional technology.

“The power papers energy storage capacity showed fantastic results in our pilot study, with the possibility of storing renewable energy on a large scale,” says Jesper Edberg, researcher at RISE and scientific leader at the Digital Cellulose Center. “Green electronics, like the power paper, will contribute greatly to a sustainable, digital society.”

Greentech power paper – a key to a fossil-free society

The transition to a fossil-free society needs to go faster. Renewable energy such as solar and wind power is a part of the transition, however it lacks efficient methods of energy storage. One of the biggest challenges for renewable energy is storing energy on a large scale to fully utilize the energy that is produced. Researchers at the Digital Cellulose Center believe that an electrode paper with the ability for high-capacity energy storage will be the solution.

The electrode paper, also called the power paper, has been a research area for many years. Jesper Edberg is one of the leading scientists in the area. Based on the previous development of the power paper by the research teams from RISE, KTH and Linköping University, the team at Digital Cellulose Center have refined the research and process for creating power electronics with organic materials.

Large scale renewable energy storage

The first prototype of the power paper was fifteen centimeters in diameter, and a tenth of a millimeter thick. It had the ability to be charged with electricity within a few seconds and it could be reused hundreds of times.

The newly re-developed power paper is made with other materials than before, it is completely composed of organic materials and has more efficient properties for high-capacity energy storage. A pilot study was conducted by the Digital Cellulose Center’s researchers and industry partners Agfa and Ahlstrom-Munksjö. The purpose was to test and verify if the power paper can be produced on a large scale. The biggest challenge was to scale up the process and take the production from the gram scale to a kilogram scale.

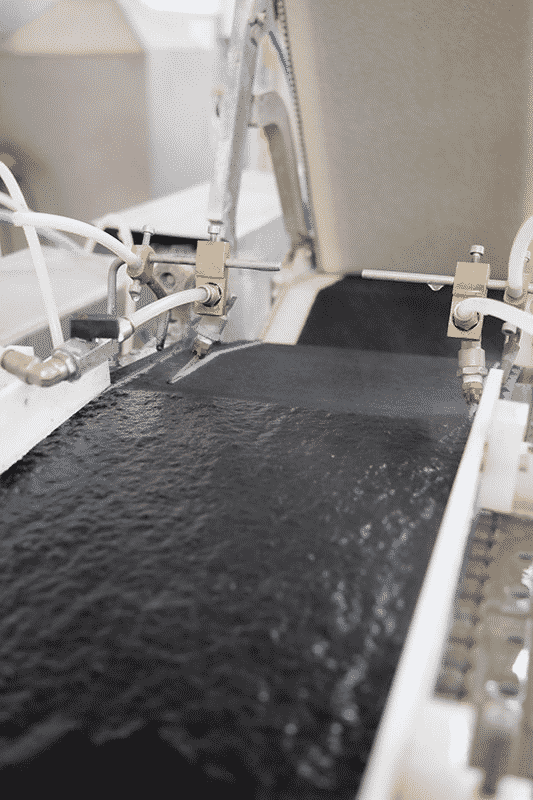

The test was successful, and the paper was manufactured in regular paper machines, with several paper roles produced, ten meters each. The paper can be used as electrodes in supercapacitors in order to test the energy storage capacity. The testing’s showed that the paper has an as efficient energy storage capacity as conventional supercapacitors.

The future of the power paper

“Our goal is to use the paper material to build prototype supercapacitors before the end of the year”, says Jesper Edberg. “In the future, we also plan to add electrochemically active materials that will enable the paper to be used in battery applications. Then the energy density would increase significantly because batteries can store more energy than ultracapacitors. Our previously research has also shown that such batteries can be manufactured from forest-based materials.”

The power paper can be used in many areas, for instance in smart packaging and in internet-of-things applications, where small and smart components collect information from the environment and communicates it to the user. These small and distributed devices must all have an energy source, like a thin, flexible, and foldable paper battery.

Cost-effective and 100% organic materials

Paper has several advantages compared to other materials. It is cost-effective and easy to manufacture on a large scale, with already existing paper manufacturing processes. Paper also has a large surface area and structure and can, therefor bind more energy-storing materials.

The power paper is made of 100 percent organic material: cellulose, conductive polymers, bio-based charcoal from coconuts. The production process gives the papers properties like durability, fixability, and it makes the paper electrically conductive.

The green power paper – A decade in the making

Ten years of research has gone into developing the power paper and in to finding the solutions on how to get the electronic renewable materials to remain in the paper, as well as in to retaining the energy storage properties over the entire surface of the paper. The result was an electrode paper, manufactured in a lab scale, with excellent energy storage properties.

The paper was first developed with support from the Knut and Alice Wallenberg Foundation (KAW) and the Swedish foundation for Strategic Research (SSF). The research and the development of the new power paper has been made in collaboration with the institutes KTH, Linköping University, and RISE, as well as industry partners Agfa, that supplied electrically conductive polymers, and Ahlstrom-Munksjö, that manages the pilot plant in France. The work was made possible by financing from Vinnova.

Production of the energy storing paper

When making conventional paper, elongated fibers are dispersed in water, a homogeneous layer is made, and then the waters is removed. To manufacture the electronic paper, the electroactive components (conductive polymers and bio-based charcoal from coconuts) must be attached to the fibers and trapped in the fiber network . The goal is to fill the paper with as much electroactive material as possible, however, using too much of the electroactive materials can make the paper not hold together. Cellulose is what binds the material together and turns it into a paper.