This post is based on Knowles Precision Devices blog that explains quasi-lumped filter technologies that combine multiple filter technologies to meet specific requirements.

There are hundreds of filter applications operating across a wide range of frequencies, which presents a challenge for filter designers since most filter designs don’t inherently operate across these wide ranges. Size, weight, power, and cost (SWaP-C) are also important considerations, so simply adding more filters to address different frequency ranges is not an attractive solution. There is, however, an alternative way of designing filters: combining filter technologies to meet the specific frequency, bandwidth, and size requirements of your application.

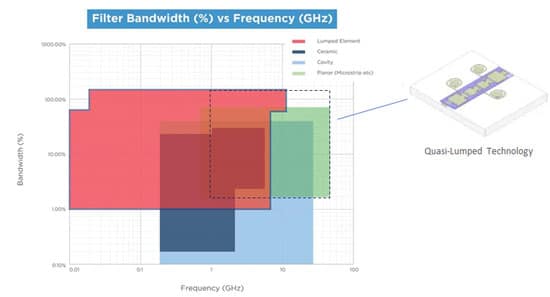

Knowles Precision Devices R&D Engineer, Jared Burdick shares his experience with this approach in our on-demand webinar, Mixing Filter Technologies to Create Higher-Value, Compact Filters. In the webinar, Jared highlights the frequency and bandwidth ranges of common filters and how combining the desired features of each can create what’s known as a quasi-lumped element filter.

What is a Quasi-Lumped Technology?

A quasi-lumped approach combines the best of lumped element filter and distributed element approaches. The quasi-lumped technology can reach anywhere from 2 percent to 200 percent bandwidth with a frequency range of 600 MHz to 30 GHz, combining that range covered by lumped element at lower frequencies and distributed element at higher frequencies. When we are managing a design for SWaP, being able to use lumped element and distributed element resonators at the frequencies where the performance versus size for each type works to our advantage, and have those resonators in the same integrated solution, allows us to field solutions that save on footprint compared to single technology approaches.

In the Webinar, Jared covers a few examples of quasi-lumped filters, like the one below in which the planar inductor is spiraled. The spiral helps make it smaller, and its thin line helps with inductance. This is a Quasi-MIM cap because the insulator is thicker and it produces less capacitance than you would see for a traditional capacitor.

A quasi-lumped approach requires integrating lumped element components, individual inductors and capacitors, into a distributed technology. Planar inductors and MIM capacitors are well suited to integration with a planar filter technology such as microstrip.

For more examples and information on quasi-lumped filters as well as other creative options for developing compact filters for devices with wide operating frequency ranges, watch the on-demand Webinar.