This article written by Akihiro Kado, KYOCERA-AVX Corporation provides insight into safety of acetonitrile supercapacitor types.

Supercapacitor Overview

Advancements in SuperCapacitor design and manufacturing have made them a mainstay component in power supplies and backup systems that require high power density output.

SuperCapacitors have now become commonplace components in many areas of modern electronic design. They bridge an important gap between batteries – used for high density energy storage, and electronic capacitors – for local power supply stabilization and decoupling.

SuperCapacitors offer the unique ability to provide large amounts of power for short periods of time. For this reason, they have found a home in applications such as electric vehicles, uninterruptible power supplies, and data storage devices. A wide variety of SuperCapacitor structures and materials have been developed, and two of the most common are based on acetonitrile and propylene carbonate solvents.

Unfortunately, even with enhanced performance, acetonitrile based SuperCapacitors have suffered slow adoption due to the lack of safety and reliability data. This is especially true in the automotive industry and other applications where rigorous safety requirements are mandated across extremely harsh environmental conditions.

Acetonitrile Supercapacitor Technology

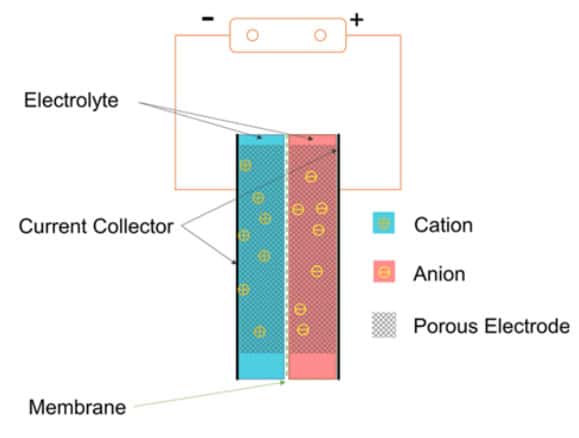

As shown in Figure 1, the SuperCapacitor structure depends on two electrolyte layers separated by a porous electrode. A Helmholtz double layer, also called the electric double layer (EDL), forms at the electrolyte-electrode interface resulting in extremely high capacitance.

These electrolyte layers require a carefully chosen base solvent chemistry. Compared to traditional solvents such as propylene carbonate, acetonitrile enables high performance at much lower temperatures due to its inherently lower viscosity.

This enhances electrical series resistance (ESR), and, as shown in Figure 2, can outperform traditional capacitors by a factor of two at -40 ℃. In addition to low ESR across temperature, acetonitrile SuperCapacitors exhibit a low leakage current rate, therefore preventing self-discharge over time. As shown in Figure 3, after 24 hours the SuperCapacitor retains much of its charge even at elevated temperatures.

Acetonitrile Safety Testing

KYOCERA AVX has conducted an extensive study of acetonitrile SuperCapacitor safety performance. Several notable tests and results are presented here to demonstrate the applicability of these devices in safety critical applications.

The first test involves puncturing the capacitor with a conductive object, something that could easily occur during an automobile crash for example. As shown in Figure 4, a nail was driven into a fully charged acetonitrile SuperCapacitor while monitoring its voltage. The voltage instantly drops to zero and the capacitor fails into an open-circuit, high impedance load. Similarly, during a short circuit of the terminals while fully charged, the capacitor exhibited no swelling or venting.

High temperature operation beyond the normal operating range is also an area of focus when considering safety. A representative acetonitrile capacitor, part number SCCT35B226SRB, was chosen for the test with a standard operating range of -40℃ to 85℃. It was charged to 2.3V and ran for 200 hours at 105℃. As shown in Figure 5, the capacitor remained stable and exhibited no precipitous reduction in capacity or increase in ESR.

High humidity also greatly impacts electronic reliability and can introduce unforeseen safety hazards. Another acetonitrile SuperCapacitor, part number SCCU25B256SRB, was chosen for 4,000 hours of exposure at 85% relative humidity and 85℃ temperature. The part was charged to 1.9V, and as can be seen in the Figure 6, it remained within acceptable limits for capacitance and ESR.

The same part number was also charged to 2.3V and exposed for 6,000 hours at 90% relative humidity and 60℃ temperature. Similarly, as presented below, the capacitance and ESR remained within the acceptable limits for the duration of the test. This is shown in Figure 7.

KYOCERA AVX Supercapacitors

Thorough, comprehensive testing across the industry continues to demonstrate the fact that acetonitrile SuperCapacitors can pass the same level of safety testing as more traditional propylene carbonate devices.

KYOCERA AVX offers these SuperCapacitors in both the SCC and SCM product series, both featuring UL 810A certification.

Figure 8 shows two series of ACN based capacitors along with their maximum capacitance and voltage ratings. Used by themselves or in conjunction with primary or secondary batteries, they provide extended back up time, longer battery life, and provide instantaneous power pulses as needed. Moreover, their acetonitrile construction offers significant improvements in ESR, especially in extremely low temperature applications.