Samsung Electro-Mechanics has started mass-producing thin-film SMD power inductors, an essential component of electric (EV) and self-driving vehicles.

As reported by The Korea Economic Daily, the company said it launched full-scale production of the part for use in EV cameras with self-driving systems. The component ensures stable power supply to semiconductors that process autonomous driving information by preventing rapid changes in current.

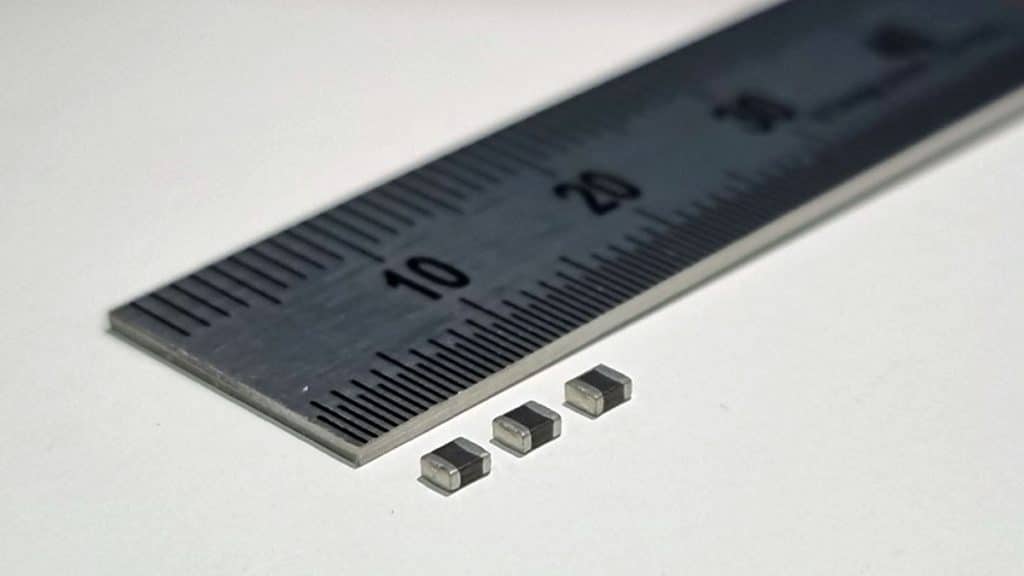

With high productivity and a small size of just 2 mm wide and 1.6 mm long, the company’s products come in two types: one with an inductance of 1.0 uH (microhenry) and the other 2.2 uH. Performance is determined by the raw magnetic material and number of coils (copper wire) woundable inside an inductor, thus putting more coils in the limited space is the key to improvement.

Samsung Electro-Mechanics’ thin-film inductor has thin coils formed on a substrate to allow the insertion of more coils than in conventional winding types, which wind coils around a magnetic material.

Because it mainly manufactures MLCC ceramic capacitors, the company has considerable know-how in materials technology. It self-developed a magnetic material with excellent characteristics and low energy loss through its material technology and experience accumulated from MLCC operations.

Another advantage is the wide range of applications of Samsung Electro-Mechanics inductors because they meet AEC-Q200, a test standard requiring high reliability for automotive electronic parts. Its power inductors can also be used in advanced driver-assisted systems and infotainment in vehicles.

The aggressive rollout of EVs and self-driving cars on the automotive market has prompted growth of related markets. The power inductor sector is seen to grow an average 9% per year to $3.6 billion in 2028, but that for inductors used in electronic vehicle equipment is forecast to grow faster at 12%.