source: ECN article

by Austin Mori, Senior Business Development Engineer, Murata Electronics North America.

The increasing demand for batteries in power-intensive applications has laid the groundwork for a charged market. Design engineers are on a perpetual hunt for solutions that achieve high-power, an extended lifespan, and maintenance-free energy harvesting. Supercapacitors deliver this and much more—like high peak load leveling, power function, and back up—all in a miniaturized package. However, this wasn’t always the case. This current go-to solution has evolved over the last several years. Having been considered a niche product not so long ago, supercaps are now ubiquitous and helping to shape the markets of tomorrow.

In the not-so-distant past, batteries were considered more suitable products in many design situations. However, with improvements in both performance and underlying technologies (of which there are more details further on in this article), supercaps have cemented their market position, especially as a storage solution in energy harvesting systems. These systems require maintenance-free, long-life options—benefits that batteries could just not deliver.

For manufacturers, it was imperative to develop supercaps that deliver excellent durability and reliability and counter degradation factors. Plus, they must enable the following:

- High Peak Load Leveling: When the electrical load is too high for the battery and voltage becomes unstable (Figure 1), high-power supercaps must assist to decrease the load. This improves quality in RF, audio, etc.

- High Power Backup: When backup energy is needed in case of an unexpected shutdown, supercaps help mitigate. Moreover, engineers can design both high energy and power backup into slim and small devices.

- High Peak Power Function: When high power is needed, supercaps deliver.

- Storage for Energy Harvesting: Supercaps can easily charge and discharge various power levels, making them ideal for unstable power generation devices.

Of course, these features must be wrapped in a miniaturized package. So how do we push the limits and make them smaller? To meet consumer demand for mobile devices with greater efficiency and functionality, manufacturers have enhanced the design and manufacturing of supercapacitors to achieve the slim packaging required today.

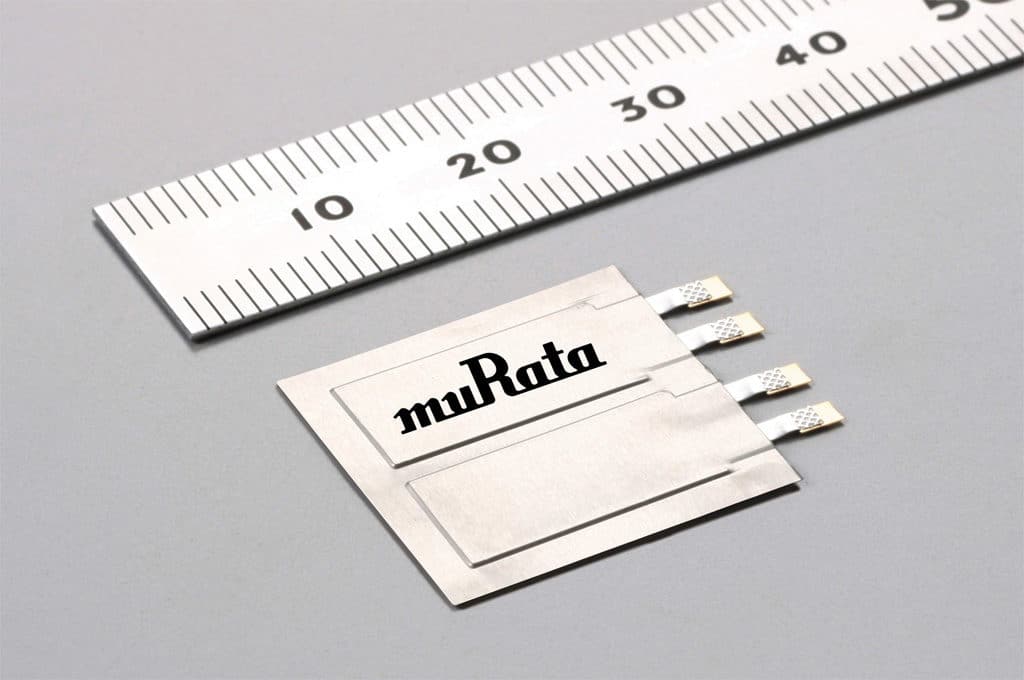

Advances in areas such as thinner laminates have helped to reduce the profile of the latest supercapacitors. (see featured image).

Consider everything from Internet of Things (IoT) products to smartcard devices. One of the close links is their miniaturized, yet robust needs. For example, wearable products require miniscule thickness, an mF order capacitance, low ESR, and capability to output instantaneous power. Because of that, manufacturers are driven to optimize construction materials and structure to deliver such a solution to design engineers. We have heard from them (loud and clear) that they are on the perpetual hunt to find new types of energy solutions that meet their limited-space, power-hungry situations. The end-result is a demand for slim packages that can be mounted into the dead space of devices.

As mentioned earlier, supercaps were not always considered for broadline applications. However, advancements have made it a reality as they can be used in place of a battery or conventional capacitor. Low-ESR and high-capacitance solutions can be used as auxiliary power supplies for assistance during peak output or backup. Additionally, they reduce the load of a battery or serve as a maintenance-free power supply in combination with a power generation element. They also decrease the size of a power supply to attain higher functionality and save energy.

When a supercap is used as an auxiliary power supply during peak output, it reduces the size of supply units, adds a higher output function, and improves overall performance. Applications include a peak-output auxiliary power supply for LPWA RF modules for IoT or smart meters, light-emitting diodes (LEDs), compact DC motor devices, and Remote Keyless Entry (RKE) systems.

Design engineers also achieve a high-output backup in a confined space by taking full advantage of a supercap’s long life, lower ESR, and smaller size compared to a battery. Notably, it can be used as a memory backup for communication devices, programmable logical controllers (PLC), and solid-state drives (SSD). When they couple these features with other benefits, supercaps improve device functions and stabilize operations by leveling large power fluctuations. This makes them ideally suited as a power supply in communications devices, audio equipment, along with security and medical/healthcare devices. Minimizing energy loss caused by an unstable input and high output, can also be deployed in sensor network systems and IoT devices to leverage energy harvesting benefits.

From a manufacturer’s standpoint, it is imperative we get in front of anticipated market needs. This means we will continue pushing the envelope to develop miniaturized products with less ESR so that the devices have increased functionality and energy-saving features in smaller packages. With that comes a steadfast focus on overcoming design challenges.

Specifically, we need to pack higher energy into smaller packages. By making the electrode material with a higher surface area, we can obtain an increased capacitance density. For lower ESR levels, we look to make the electrolyte solution higher in electrical conductivity to lower the internal resistance. In terms of performance specs, the general range is 10 mF to 5000 F in capacitance and approximately 1 mOhm to 500 Ohm. Looking to the next 12 to 18 months, we anticipate that capacitance density will experience a 30 percent increase and ESR will improve by 20 percent.

Finally, there is the ever-present need to decrease the footprint. Packaging technology is one of the most important factors in supercap reliability. The smaller and smaller they become, the larger the challenge. To overcome this, it is incumbent upon manufacturers to leverage technology leadership, market expertise, and material know-how to deliver leading-edge products and solutions.