This article written by George Zhang, KYOCERA-AVX Corporation explains Tantalum and NbO Capacitors failure modes.

Introduction

The automotive industry has become highly dependent on advanced sensing and computing.

Starting in the mid-twentieth century, the development of dense, reliable, and stable capacitors has been instrumental in advancing high speed computing and high performance electronics.

The demands on these capacitors have increased substantially, requiring high-temperature tolerance, harsh environmental reliability, and ever-decreasing parasitic parameters such as equivalent series resistance (ESR) and inductance (ESL).

Tantalum and niobium oxide capacitors have been two of the most notable contenders to meet these requirements. Though similar in construction, their failure modes are nuanced and require a careful understanding to ensure a successful design for a particular application.

Tantalum Capacitors

Tantalum pentoxide is the dielectric layer with semiconducting features that will only conduct current in one direction. In the reverse direction, an oxide layer readily grows under anodic conditions that act as a highly effective insulator. The anode is formed from pure tantalum powder to build a capacitor.

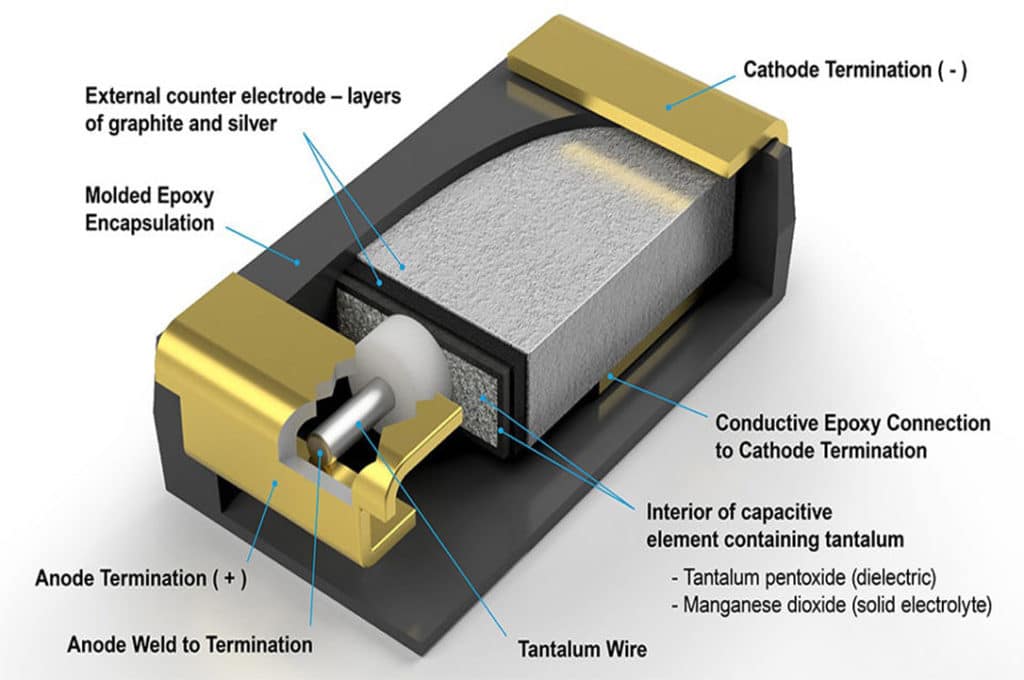

An oxide layer, typically Ta2O5, is grown as a dielectric and is then electrically connected using a solid or wet electrolyte. As shown in Figure 1, this material stackup can be packaged to form a high performance surface mount capacitor.

Tantalum capacitors are regarded highly in the electrolytic capacitors family for their large capacitance per unit volume and generally stable operating characteristics. They exhibit self-healing properties and typically provide low electrical series resistance (ESR) with favorable AC impedance characteristics.

For these reasons, the two primary applications of tantalum capacitors in circuit design have been as high capacity energy storage elements and as ripple filtering components in power supplies.

Niobium Oxide NbO Capacitors

Much like their tantalum counterparts, niobium oxide capacitors are constructed using the anode, oxide, electrolyte construction. The anode material is typically passivated niobium or niobium monoxide. The dielectric is grown as niobium pentoxide, and the solid electrolyte is composed of manganese dioxide, as shown in Figure 2.

Like tantalum capacitors, niobium capacitors exhibit many favorable characteristics, including high volumetric capacitance, stable operating characteristics, and a self-healing mechanism for long-term reliability. In addition, when compared to tantalum, niobium is abundant and readily available as a raw material making the capacitor supply chain less susceptible to market fluctuations. Most importantly, niobium offers several properties that make its failure modes more graceful than comparable capacitors.

Failure Mode Comparison

Tantalum capacitors often find applications in filtering circuits where a large bulk capacitance is required. Unfortunately, these devices suffer from poor tolerance to large overages in voltage or current. A strong surge in current, a high ripple in current, or a high voltage across the circuit can quickly lead to failure. This is due mainly to the reactivity of the constituent metals with oxygen.

When a dielectric breakdown occurs, the heat generated by the large current passing through the defect site will cause the dielectric layer to be quickly destroyed. This, in turn, allows the pure tantalum anode to interact directly with oxygen at high temperatures. The resulting chemical reaction releases a significant amount of heat energy.

On the other hand, niobium capacitors use a niobium oxide anode, which is already oxygen rich and stable when exposed. During a dielectric breakdown event, the temperature rise is significantly lower than in the tantalum case. The niobium oxide layer tends to grow at elevated temperatures, resulting in a “self-arresting” mechanism. The benefit is a reduction (up to 95%) of the ignition failure mode of niobium oxide capacitors when compared to conventional tantalum devices. For this reason, niobium oxide capacitors are regarded as one of the safest capacitor technologies on the market.

Switching to Niobium Oxide Capacitors for Certain Applications

Given the seriousness of the tantalum dielectric failure mode, certain applications such as automotive, health care, and military may find significant improvements in safety by switching to niobium-based devices. The stable sub-oxide and self-arresting mechanism alone may offset any performance losses from parasitic resistance and inductance.

When used for switching power supply circuits, the niobium oxide capacitor does not need to be derated in voltage to the same degree as their Tantalum counterparts. High reliability can be achieved with no derating factor when resistance protection is added.

KYOCERA AVX offers a wide range of niobium oxide capacitors under OxiCap® trade name with high-reliability levels of 0.5%/1000hrs at 85°C or better, high safety technology with non-burning high resistance failure mode, and high break-down voltage. The OxiCap® series is available as low ESR, High CV, low profile, up to 125°C, and multi-anode technologies. It is environmentally friendly and

RoHS compliant technology in the same form, case size, and same or similar technical performance as standard tantalum capacitors. Capacitors are offered in voltage ratings up to 10V, and a majority of the series meet AEC-Q200 requirements.

Further reference links with more detailed tech information: