Texas Instruments has developed a 3D inductor that can be molded around a power chip for a smaller module with less EMI.

The 3D inductor in the TI Magpack technology was created with a proprietary material and enables a 6A power module that reduces EMI by 8dB and improves efficiency by 2% while being up to 50% smaller than TI’s previous modules.

“Combining a power chip with a transformer in one package is the focal point for us and key to the next frontier of power in a world where the space allocated to power is shrinking year on year,” said Roja de Cande, product line manager at TI.

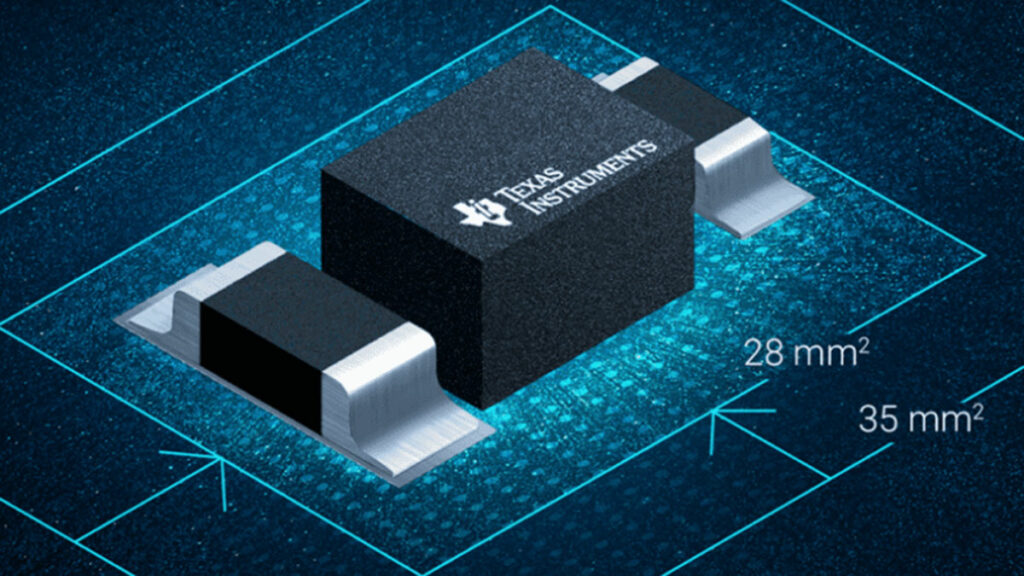

Three of the six new devices, the TPSM82866A, TPSM82866C and TPSM82816, are the industry’s smallest 6A power modules with a power density of nearly 1A per 1mm2 of area.

“These use 3D package molding to maximise the package area where we integrate the inductor over the chip with new material,” said Anton Winkler system engineer at TI.

“You can picture it as a 3D stack of the IC, inductor and overmolded packaging and this helps us shrink the size dramatically. It is not a stack where the inductor touches the die but surround the silicon but we mold the inductor around the internals.” The modules are assembled and packaged internally at TI.

“We fine tune the inductor to the needs of the silicon. We kept the switching frequency and adjusted the inductor accordingly to increase the efficiency across the entire load range,” he said.

There are six modules covering currents of 6A, 5.5A and 3A with 17% lower thermal management that gives a 10 C improvement in the safe operating area. These are also up ot 23% smaller than competing modules.

The power modules with MagPack technology are shielded, and not just a shielded inductor. The entire die, the inductor, the switching node are enclosed in a shielded package. The smaller size of power modules and the optimized routing inside the package make for shorter, smaller routings of noisy signals, in both the power module and the system. Peak emissions are reduced by about 2dB in the horizontal polarization and 8dB in the vertical polarization.

TI plans to integrate a noise filtering capacitor. This is usually already on the board and so is part of the existing bill of materials but will be include din the package in future versions.