Lasers nowadays are one fabrication tool among many for industrial production, measuring and testing applications. Industrial lasers commonly employ a pulse grade capacitor to generate and deliver the energy required to test, measure or make the product or service on offer. In this article, we examine the importance of the self-healing characteristics of metallized film dielectrics used in pulse grade capacitors for industrial laser applications.

Lasers in industry

Lasers are used in industry for a huge variety of applications. These can be divided in to 3 main types:

- materials processing

- inspection and scanning

- straight line tools

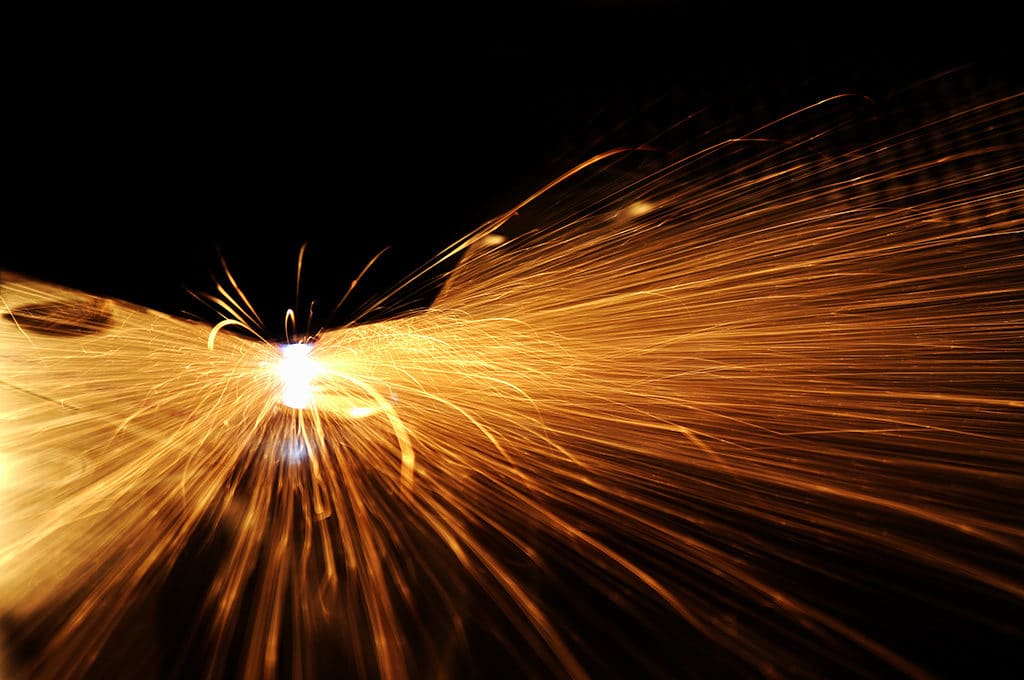

Materials processing applications include cutting, welding, drilling, marking and surface heat treatment (these is a subclass of materials processing known as micro materials processing e.g. semiconductor manufacture, where “doing it” by laser is the only way). Inspection and scanning applications include assembly line inspection, parts inspection e.g. welding joints, and POS scanning. Lasers find applications as straight line tools in the construction industry for surveying and building.

Lasers in industry are usually an expensive investment, and like any other capex, they need to deliver an economic return. In materials processing applications in particular, they are subjected to intensive on-times and high repetition rates; in short, they need to work. Downtime caused by the catastrophic failure of a pulse capacitor is an expensive hiatus. Each missed shot represents lost revenue.

This is where the self-healing mechanism of a metallized film capacitor dielectric makes all the difference.

Metallized film as a dielectric in high pulse capacitors

Metallized polypropylene film is the dielectric most often used in capacitors designed for high powered lasers. Polypropylene film is a low loss dielectric with a high dielectric strength. Low dielectric loss is essential for high repetition rate capacitors because substantial heat can be generated at high RMS currents.

The electrodes are vapor deposited onto a thin film of polypropylene dielectric material. This dielectric configuration is able to handle high reversals and high peak current.

The capacitor itself is designed so that the current path can withstand both the high amperage and the mechanical shock of the discharge. A low inductance design is also critical as inductance increases the pulse duration.

But the most important feature to any operator of a production facility is the way that such a capacitor fails.

The metallized film possesses self-healing characteristics that provides a “soft” failure mode; with controlled self healing the total capacitance of the device is effectively divided into several million “small capacitances”. The weak points in the dielectric are isolated by the self-healing mechanism, and the device continues to work, so that the primary mode of failure for a metallized film capacitor is a gradual reduction in capacitance, and not a short circuit.

This has the important advantage of allowing equipment operators to choose when to replace capacitors by defining an end-of-life consistent with the equipment requirements. This reduces operating costs and mitigates the expense of taking the equipment off-line in the event of a catastrophic failure.

Leading manufacturers Aerovox and AVX specify metallized polypropylene for their ranges of pulse grade capacitors.