This article written by Tomohiro Imai, ASC Product Manager, Murata discusses how development of high temperature film capacitors contribute to advancing of automotive electronics.

The electrification of a vehicle goes far beyond the transition from internal combustion engines (ICEs) to electric motors. Alongside the powertrain transformation, countless smaller systems are also moving away from mechanical based systems to electronic ones.

This comprehensive shift towards electronic systems enables simpler integration and improved diagnostic measures, as well as the potential for increased reliability due to a reduction in complex mechanical systems. This trend can be clearly seen in the rise of by-wire steering and braking systems which can more easily integrate into highly electric designs that wish to support higher levels of autonomous operation.

However, the task of electrifying vehicles is far from simple. Reliability is of utmost importance in the automotive industry, as vehicles must have long lifetimes. Many subsystems are designed to last the entirety of the vehicle’s lifespan and are impractical to repair in case of failure, due to their location and the complexity involved in repair.

As a result, any components specifically designed for automotive use must possess inherent reliability and be capable of handling the challenging environmental conditions, such as heat and vibration, that exist within electric vehicles.

For automotive manufacturers and tier one suppliers, understanding the challenges that electronic components encounter in electric vehicles and selecting the right components are crucial to ensure product reliability.

The Challenges Facing Automotive Electronic Components

Component manufacturers and automotive designers encounter a multitude of obstacles during the production and selection process, but the fundamental challenge is that vehicles are not an ideal environment for electronic components. High temperatures, weight and packaging constraints all place definite limits that components must obey. Excessive weight or bulky components in EVs can result in severe consequences, such as reduced range or complicated manufacturing processes.

Inside EVs, the proliferation of high-power systems, such as inverters and charging systems, has meant a vast amount of sensitive electronic components are now tightly packaged into harsh operating environments. For automotive design engineers who need to ensure system reliability, this is a significant challenge that cannot simply be solved by adding more heat sinks or insulation as any additional weight or costs undermines a vehicle’s value to the consumer.

Furthermore, there is no room for compromise when it comes to component reliability components in EVs. Fixing or replacing circuits buried deep within an EV is a complicated and expensive process. The accessibility of components within systems like the on-board charger (OBC) is often incredibly challenging, with the task further hindered by the presence of high-power electronics. Moreover, consistent and systematic component failures rarely go unspotted in the automotive industry and can undermine consumer trust, leading to significant financial repercussions for manufacturers. Therefore, even for small components like capacitors, automotive OEMs will benefit from variants which are more compact, more reliable and have higher thermal limits.

EV Thermal and Packaging Considerations

Thermal management has long been a key element of automotive design, but the challenge has moved from ICEs and radiators to electronic components and heatsinks.

One of the most critical areas of EV thermal management is around the OBC. The OBC converts the AC supply from the grid or charging station into DC to charge the high-voltage battery pack. It serves as a crucial component in the charging infrastructure of electric vehicles, managing the power flow and ensuring efficient and safe charging of the vehicle’s battery.

Depending on the design, the AC feed can support a supply of up to 22kW and can be single or three phase. Similarly, the DC output voltage can range from 400V up to 800V and needs to be sustained for long periods of time during charging. Throughout this process, OBCs generate heat due to power conversion losses and electrical resistance. The pursuit of faster charging times and the ongoing miniaturization of OBCs, with the aim of saving space and reducing weight, are further compounding the complexities of thermal management.

The thermal environment around the OBC is a complicated matter, with both immediate heat load and deeper heat soaking caused by prolonged charging on the surrounding components and the environment present. Inadequate heat management, caused by the use of under-specified heat sinks or components with insufficient thermal limits, can lead to temporary or permanent failure of this critical vehicle system.

Despite the usage of heat sinks in EVs to dissipate heat from components like power semiconductors and capacitors present in the OBC, the operating temperatures still remain elevated due to the potential drawbacks associated with larger cooling and heat sink alternatives. In systems like an OBC or an air condition electric compressor, vital electronic components such as smoothing capacitors might experience temperatures of around 100°C or higher.

Consequently, the selection of components holds a similar significance to the design and implementation of heat sinks in OBCs, as both are imperative for ensuring the reliability and longevity of a vehicle. Furthermore, the integration of smaller packaged components with increased thermal capabilities can assist in the reduction of vehicle electronics’ size, as well as the minimization of heat sink sizes.

Murata’s High Temperature Film Capacitors

Film capacitors are fundamental components in automotive electronics, used for energy storage and voltage regulation across a range of electrified vehicle systems. In EVs, film capacitors play a vital role in smoothing power delivery and ensuring the reliability of critical systems, such as electric compressors, OBCs and future applications like wireless power transfer systems (WPT). Yet, conventional film capacitors face limitations in meeting the stringent requirements of modern automotive applications, particularly in high-temperature environments.

At present, film capacitors utilized in automotive applications typically have a guaranteed temperature limit of 105°C. However, Murata has recently introduced a novel film dielectric material with exceptional heat resistance properties. Leveraging this material, and with its partner Shizuki Electronic, they have successfully brought to market a film capacitor capable of continuous operation at 125°C and a peak of 135°C for a specified time limit.

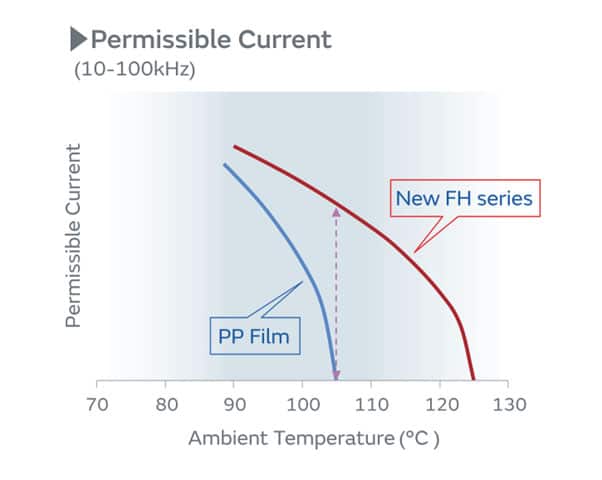

This joint venture between Murata and Shizuki started in 2008 and the new product, Murata’s High Temperature Film Capacitors (HTFC) or FH series, represent a paradigm shift in automotive capacitors, addressing the shortcomings of conventional film capacitors. Because of the utilization of a unique heat-resistant dielectric material, the FH series exhibits a higher power density and increased allowable ripple current under high temperature environments, surpassing that of conventional PP film capacitors. This characteristic becomes more apparent within the high frequency range. For instance, when the ambient temperature reaches 105°C, the Polypropylene (PP) film capacitor would already be at its maximum allowable ripple current. However, due to the higher heat resistance of the FH series, the allowable ripple current can be significantly increased (Figure 1).

While there have been previous instances of high heat resistance film capacitors, concerns have been raised regarding the efficacy of the self-healing function at elevated temperatures and the potential for short-circuit failures. However, the FH series addresses these concerns with its functional self-healing capabilities even at the high temperature conditions associated with EV power systems. By offering unparalleled reliability and performance in high-temperature environments, this technology also allows engineers to place smoothing capacitors closer to hot power components, leading to a reduction in the overall circuit footprint.

For EVs, the FH series miniaturized design, higher operating temperature and increased ripple current make it ideal for demanding OBC, electric compressor and WPT functions (Figure 2).

The FH series, available in 4, 10, 15, 20μF at 500Vdc and 3, 10, 15, 20μF at 850Vdc, serves as a smoothing capacitor in these applications, enhancing the power density of the systems and reducing reliability concerns in high-temperature conditions. The increased packaging density and higher operating temperature enable electronic design engineers to create more compact systems without compromising longevity. This is further aided by the lower cooling requirement, potentially allowing for a reduction in heat sink size.

Impact on Industrial Designs

The introduction of Murata’s FH series capacitors also benefits industrial applications, such as motor control and photovoltaic power inverters. For both deployment types, reliability is once again critical, and Murata’s FH series offers a notable advantage. It provides enhanced power density, elevated thermal thresholds, and improved reliability, surpassing existing solutions. Additionally, it can allow for system downsizing when compared to conventional PP capacitors (Figure 3).

The increased thermal operating limit facilitates the placement of FH series capacitors in closer proximity to hot power components than is typically allowed, helping to reduce inverter size. In certain designs, this can also enable a reduction in casing or heat sink dimensions, leading to lower material usage and costs.

Conclusion

Electrification is fundamental to the future of the automotive industry, yet its success hinges not only on the performance of the electric drivetrain but also on the reliability of even the smallest capacitors. As the automotive and industrial sectors embrace electrification, the demand for innovative solutions that address power density concerns without compromising reliability becomes increasingly pronounced. In this dynamic landscape, the role of capacitors, particularly high-temperature film capacitors like Murata’s FH series, becomes paramount.

Murata’s FH series capacitors represent a shift in capacitor technology, offering engineers the flexibility needed to push the boundaries of automotive and industrial design while ensuring uncompromising reliability. With its innovative construction and high operating temperature, the FH series capacitors enable designers to realize the full potential of electrification, driving forward the evolution of automotive and industrial design.