Engineers at Cornell Dubilier Electronics use simulation apps to evaluate and optimize custom capacitor designs. These apps allow design and manufacturing engineers to quickly explore configurations on-site, bypassing the complexity of the underlying computational model.

Capacitors are ubiquitous across common electrical devices used today, as well as in applications where extreme conditions must be considered. In each of these applications for which capacitors are necessary, the requirements can vary greatly. A capacitor may require an exact power specification, may need to function within a certain temperature range, or be made of specific materials.

One of the biggest manufacturers of custom capacitors used around the world, Cornell Dubilier Electronics, develops capacitors for some of the most demanding military and aerospace applications, including fighter jets and radar systems, as well as civilian applications such as wind turbines and solar energy.

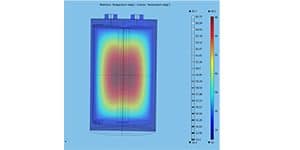

Engineers at Cornell Dubilier use mathematical modeling and custom simulation apps to fine-tune the design of custom capacitors.

“By using COMSOL Multiphysics and its Application Builder I can create high-fidelity multiphysics models and build apps based on them, which allows my colleagues in other departments to test different configurations and pick the best design,” comments Sam Parler, research director at Cornell Dubilier.

Read the entire article by clicking on the link here