Source: Alter Technology article

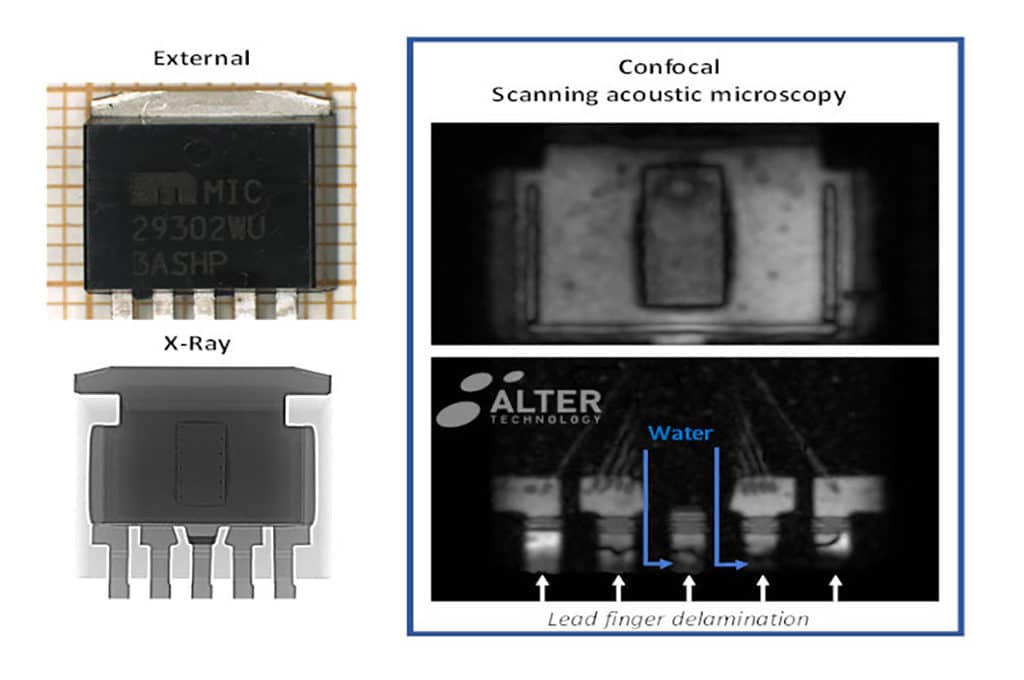

Scanning acoustic microscopy (SAM) is used to locate the paths for water ingress in plastic encapsulated microelectronic systems. This is so thanks to the capability to analyze hidden delamination on surface-breaking parts.

Sample & Method

High-current low dropout regulator encapsulated in a TO-263 package is inspected by confocal scanning acoustic microscopy (C-SAM). Probe frequency and inspection procedure are adapted to the internal structure of this plastic encapsulated microelectronic part.

In this case the architecture of the system includes features at different depths within a thick package. Therefore, we perform multi-depth confocal analyses at the different focal planes of interest. Such analyses are only possible by combining low and high frequency transducers with suitable filters to improve the resolution. A-scan inspection is used to confirm deviation observed by scanning acoustic tomography.

Remarks

Thorough scanning acoustic inspection is used to confocally inspect features at different depths (C-mode SAM). The technique reveals the systemic delamination on all the lead fingers. Such a kind of delamination on surface breaking features represents an important risk of entrance of water and other contaminants from the outside environment. In fact, darker areas highlighted with blue arrows are ascribed delimitated areas partially filled with water, which reduces the intensity of the reflected beam.

Assessment as per different test methods

In Alter Technology scanning acoustic tomography inspection is conducted in accordance with different inspection methods as summarized in the following table. In this case the delaminated area does not reach the active zone, i.e. it does not extend over the full length of the surface breaking part. Therefore, the observed delamination is acceptable.

The observed water features are also an important issue to take into account, although they are not considered by the inspection methods in the table. In addition, there is a severe risk if the delaminated area increase, for instance, due to mechanical or thermomechanical stress. Thus, it is highly advisable to submit this specimen to thermomechanical stress (e.g. temperature cycling test) to study the evolution of the observed features.

| Specification | Partial delamination of a surface breaking part (lead) | |

|---|---|---|

| 1 | J-STD-020E | Compliant |

| 4 | ESCC 25200 | Compliant |

| 7 | PEM-INST-001 | Compliant |

| 10 | MIL-STD-1580 | Compliant |