This article explains flying capacitor circuit configuration features and benefits.

The flying-capacitor size is significantly smaller than the required DC-link capacitor used in traditional booster topologies with the same power rating nevertheless there are some issues to be addressed with this topology. The article is based on Knowles blog article written by Jordan Yates and EE Power article by Viktor Antony.

Key Takeaways

- Flying capacitors are smaller, efficient alternatives to traditional DC-link capacitors in power electronics like inverters and battery management systems.

- They help balance voltage levels, enhance power quality, and improve system efficiency by storing and releasing energy as needed.

- Key considerations for flying capacitors include sizing, voltage balancing, and pre-charging to prevent system failures during operational changes.

- Ceramic capacitors provide several advantages, such as high dielectric constant, non-polarity, low ESR, and compact size, making them ideal for flying capacitor applications.

- In conclusion, flying capacitors offer a cost-effective solution with significant benefits for solar inverters and EV applications.

As demand for high-efficiency and high-power-density inverters continues to grow, the so-called “flying” capacitor multilevel inverter is emerging as a strong choice for many power electronics systems.

Since these capacitors can “float” to different electric potentials depending on the connected semiconductor switching structure and state, they help balance out voltage level differences due to manufacturing tolerances, temperature variations, and other factors.

These capacitors are also helpful in balancing voltage across the structure by temporarily storing and releasing energy as needed, increasing power density and quality, and optimizing the use of existing voltage availability.

What is a Flying Capacitor?

A flying capacitor is a type of capacitor that is used in multi-level inverters, common in applications such as electric vehicle (EV) inverters, battery management systems (BMSs), renewable energy systems, and other power electronics. The main function of a flying capacitor is to store and transfer energy between different levels of the inverter, using multiple capacitors connected in series and parallel to produce a desired voltage level.

Example I. : Flying Capacitors in a Battery Management System

Popular application areas for flying capacitors include EVs and solar inverters due to their lightweight, compact nature, and ability to help even out voltage and extend longevity of components. For example, within an EV BMS, a flying capacitor can be used to smooth out fluctuations in the voltage of the battery pack. The battery pack in an EV typically consists of many individual cells connected in series and parallel, and these cells can have slight variations in their voltage levels due to manufacturing tolerances, temperature variations, and other factors.

The flying capacitor can be used to balance the voltage across the cells by temporarily storing and releasing energy as needed. This helps ensure all the cells in the battery pack are operating at optimal voltage levels, prolonging the overall life of the battery pack. Additionally, the flying capacitor can help reduce the harmonic distortion of the voltage waveform, improving the overall power quality of the system.

Example II. : High Efficiency Solar Inverters

Using high-efficiency solar inverters is reaching more and more popularity in a design, however, it is not the most economical. To achieve a cost efficient solution, not only the inverter has to be low cost and high efficient, but also the booster stage.

The flying-capacitor booster solution can increase the efficiency while being still cost-efficient. However, it has also some challenges as capacitor sizing, balancing and the pre-charge.

Flying Capacitor Design Considerations

Sizing of the Flying-Capacitor

The voltage supplied by a flying-capacitor has a key role in this topology. To keep the voltage ripple on the capacitor low, a suitable capacitor size is needed. To determine the needed capacitance, the switching frequency and the maximum allowed voltage ripple need to be considered. The size of the capacitance can be calculated as:

where dUFC is the maximum allowed voltage ripple, Ipeak is the maximum current, and fSW is the switching frequency of the transistors.

Balancing of the Capacitor Voltage

For the appropriate operation the flying-capacitor, voltage has to be half of the output voltage. To achieve this, it must be regulated at all time. This can be done by changing the operation modes.

Pre-Charge of the Flying Capacitor

In case when all the control signals of used transistors are low, the flying-capacitor voltage cannot be regulated. In that operation an extra effort is needed to keep the flying-capacitor voltage on the safe side. Failing to eliminate the overvoltage on the semiconductors may cause a fatal error in the system.

There is a method proposed by Mitsubishi Electric Corporation [1] to protect the flying capacitor booster, when there are no control signals (e.g.: during startup).

There are two operation modes, when all the transistors are OFF: 1) When the input is applied and the output is equal with the input (e.g.: startup), and 2) when the input is zero and the output is not. This happens, for example, when one string is not connected to the circuit and other boosters are working. In both two cases the voltage of the flying-capacitor is zero, and the voltage sharing of the two transistors is not defined. To keep the voltage level of the semiconductors below the breakdown voltage, additional balancing has to be used.

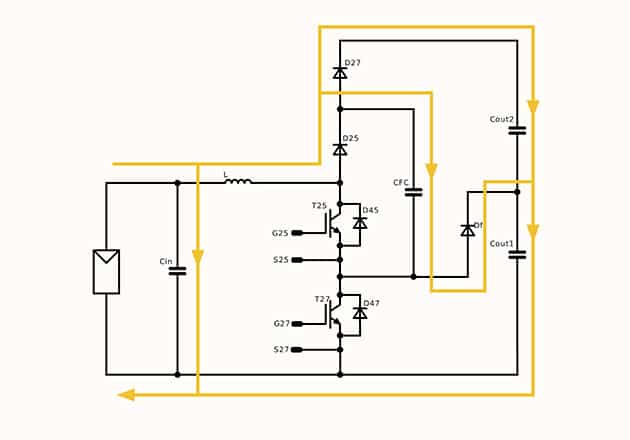

During startup the current flows through the two diodes and charge the output capacitance. In this case the output voltage is equal to the input voltage, while the flying-capacitor voltage is zero. This is dangerous for the lower switch. To eliminate this problem, another current path has to be added, in which the current can charge also the flying capacitor. For this a diode can be used, a cathode of which has to be connected to a capacitive voltage divider, where the lower point of the flying-capacitor is clamped at the half of the DC-link voltage. This can be seen on Figure 1.

Ceramic Capacitor Benefits

Ceramic capacitors can offer number of benefits as flying capacitors. They are non-polar devices unlike the other electrolytic capacitors and offer high capacitance and voltage range compare to the other electrostatic capacitor types. Because of the physical properties of ceramic capacitors, many companies are choosing this route to leverage the benefits of ceramic, including:

- High Dielectric Constant: Ceramic capacitors can store a large amount of energy in a small package.

- Non-Polar Capacitor: Ceramic capacitors are non-polar devices, so the voltage polarity is not of a concern.

- Low Equivalent Series Resistance (ESR): Ceramic capacitors can transfer energy quickly and efficiently.

- Size and Lifespan: Ceramic capacitors are small and lightweight with a long lifespan, which helps reduce the size and weight of the inverter, making them ideal for use in compact electronic devices.

- Speed of Transfer: Ceramic capacitors can quickly transfer energy between different levels of an inverter, helping reduce losses and improve the overall efficiency of the system.

Conclusion

The flying-capacitor booster is a high-efficient, low cost solution for solar inverter or battery management applications.

The main advantages are the frequency multiplication, the lower semiconductor voltage, the lower voltage and current ripple, the lower switching losses, and the low EMI emission.

The flying-capacitor size is significantly smaller than the required DC-link capacitor used in traditional booster topologies with the same power rating. The challenge is to regulate the voltage of the flying-capacitor especially when all the transistors are in OFF state (i.e.: before the converter is turned on). The balancing can be achieved by state regulation. Also the pre-charge challenge can be solved easily by additional diodes based on Mitsubishi Electric Corporation’s patent [1]. With these diodes the flying-capacitor booster is a cost efficient alternative for the other booster solutions with higher efficiency.

References

[1] T. Okuda and H. Ito, “DC/DC POWER CONVERSION APPARATUS”. United States Patent US 2013/0021011 A1, 24 01 2013.

Flying Capacitors – FAQ

A flying capacitor is a capacitor used in multilevel inverters and power electronics systems. It temporarily stores and transfers energy between voltage levels, helping to balance voltage differences caused by tolerances, temperature, or load variations.

They are widely used in electric vehicle battery management systems (BMS), renewable energy inverters such as solar systems, and other high-efficiency power electronics applications.

Flying capacitors improve power density, reduce voltage ripple, balance cell voltages, and enhance efficiency. When ceramic capacitors are used, they also provide long lifespan, low ESR, and compact size.

Key challenges include correct sizing to minimize ripple, maintaining voltage balance at half the output voltage, and ensuring safe pre-charge during startup to avoid semiconductor stress.

How to Design a Flying Capacitor Circuit

- Define system requirements

Determine the inverter application (EV, solar, or BMS) and establish the required voltage and current ratings.

- Calculate capacitor size

Use switching frequency, peak current, and maximum allowed voltage ripple to calculate the required capacitance value.

- Ensure voltage balancing

Implement control strategies to regulate the flying capacitor voltage at half of the output voltage for stable operation.

- Add pre-charge protection

Incorporate additional diodes or circuits to safely pre-charge the capacitor during startup, preventing overvoltage stress on semiconductors.

- Select capacitor type

Consider ceramic capacitors for their non-polarity, low ESR, compact size, and long lifespan, ensuring high efficiency and reliability. Electrolytic capacitors may provide higher capacitance value but limitation as polar devices. Film capacitors may work for higher voltages but it may be more bulky and limited by temperature.