After years of working with designers that develop medical implantables, Knowles Precision Devices established the MD Series of medical-grade ceramic capacitors specifically for these teams. The MD Series encompasses three product families, including C0G, X7R, and X5R monolithic ceramic chips.

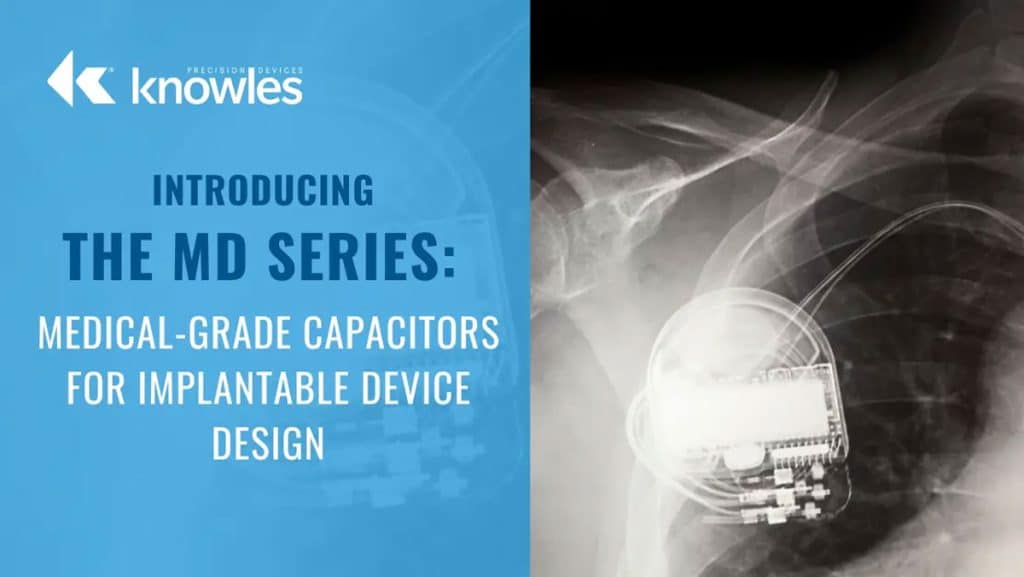

A medical device is considered “implantable” if it’s partly or totally introduced into the human body via surgery or another medical intervention, and it’s intended to stay there for a long period of time. According to the American Medical Association (AMA), approximately 10 percent of Americans will receive an implantable device during their lifetimes. To serve consistent, often life-sustaining functions, implantables require high-reliability components that guarantee long-term performance.

To achieve the reliability needed for medical implantable devices, Knowles Precision Devices offers medical-grade components. In addition to robust design techniques, Knowles offers additional screening based on two long-standing reliability specifications—MIL-PRF-55681 and MIL-PRF-123. Our components go through Group A testing for a high level of safety. The medical industry has no unique reliability specification for passive devices used in medical implantables. Designers generally rely on MIL-SPECS that have been around for decades and are accepted for defense, aerospace, military, and medical applications.

The MD series is designed to offer the broadest variety of medical-grade capacitors to accommodate any number of implantable designs. With a clear, comprehensive catalog that lists full specs, including what reliability testing a component receives, engineers can have confidence in the compatibility and quality of their selections.

Having this information readily available also saves time in ordering and sourcing, which expedites the overall production process. With our new catalog of offerings, it’s easy to identify which components fall into the MD Series and check the availability of stock that requires Group A testing.

Further, all of our screening options are tailored for selectable-combination testing. This reduces or eliminates the cost associated with developing and maintaining device-specific documentation packages and better preserves each component’s performance integrity. In other words, designers can rest assured that the high-reliability component they tested in their prototype will perform as expected in production.