Researchers from University of Science and Technology, Hefei, China published new research on edge-nitrogen doped porous carbon for energy-storage potassium-ion hybrid supercapacitors in Energy Material Advances.

“The development of cost-effective and high-performance electrochemical energy storage devices is imperative,” said paper’s corresponding author Wei Chen, a professor in the School of Chemistry and Materials Science, University of Science and Technology of China (USTC). “Currently, lithium-ion batteries still dominate the market, but they are limited in both lithium as a resource and in their power densities.”

Chen explained that potassium-ion hybrid supercapacitors (PIHCs) have several significant advantages as an alternative to lithium-ion batteries, especially to dual-carbon potassium ion hybrid capacitors (DC-PIHCs) with capacitive carbon cathode and battery-type carbon anode due to their low cost and high power/energy density.

“Currently, for battery-type carbon anodes, the slow reaction kinetics and huge volume expansion result in poor rate performance and short long-cycle lifespan, which fail to match with those of capacitive cathodes,” Chen said. “Therefore, it is significant to develop carbonaceous anodes with superior rate performance and long cycle life for DC-PIHCs.”

Various strategies have been developed for adjusting the microstructure of carbonaceous materials, such as heteroatom doping and porous structure construction to improve electrochemical performance. Nowadays, the synthesis methods of porous carbon usually adopt various templates, which increase the cost and generate a lot of byproducts.

Moreover, different types of nitrogen doping exhibited distinct roles in carbon materials. It was widely accepted that pyrrolic nitrogen and pyridinic nitrogen are electrochemically active sites in carbon materials, while graphitic nitrogen doped into the carbon lattice has no effect on K+ adsorption. Therefore, it is necessary to explore facile and economical strategies for the synthesis of high-concentration edge-nitrogen (pyrrolic nitrogen and pyridinic nitrogen) doped porous carbons.

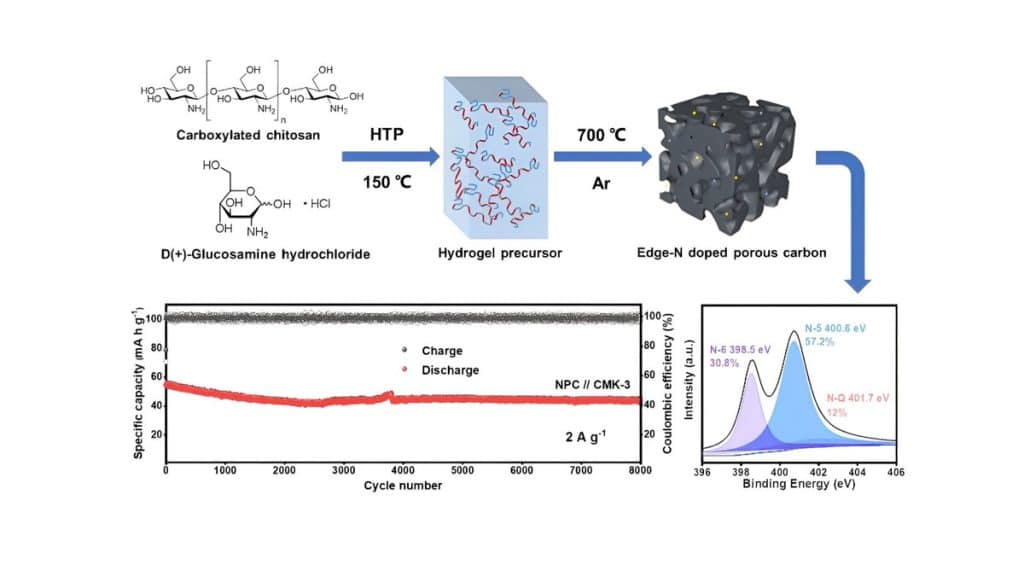

Chen said, “In this paper, we developed a template-free strategy for preparation of high-concentration edge-nitrogen doped porous carbon (NPC) anode of DC-PHIC derived from D (+)-glucosamine hydrochloride (DGH) and carboxylated chitosan (CC), which includes two steps of hydrothermal polymerization and high-temperature carbonization. Our aim is to provide inspiration for future research in the field.”

“BET and XPS analysis demonstrated that NPC presents large specific surface area (523.2 m2/g) and exhibits high edge-nitrogen doping level of 5.19 at%, which improved K+ adsorption and intercalation capabilities,” Chen said.

Abstract

Developing facile and economical strategies to fabricate nitrogen-doped porous carbon anode is desirable for dual-carbon potassium ion hybrid supercapacitors (PIHCs). Here, a high-concentration edge-nitrogen-doped porous carbon (NPC) anode is synthesized by a template-free strategy, in which the total content of pyrrolic nitrogen and pyridinic nitrogen accounts for more than 80% of the nitrogen atoms. As a result, the NPC anode displays a capacity of 315.4 mA h g−1 at a current rate of 0.1 A g−1 and 189.1 mA h g−1 at 5 A g−1. Ex situ characterizations and density functional theory calculations demonstrate the high-concentration edge-nitrogen doping enhances K+ adsorption and electronic conductivity of carbon materials, resulting in good electrochemical performance. The assembled NPC//CMK-3 PIHC delivers an energy density of 71.1 W h kg−1 at a power density of 771.9 W kg−1 over 8,000 cycles.

Conclusion

In summary, a template-free strategy has been developed for the preparation of high-concentration edge-NPC as anode for DC-PIHC, which simplified the synthesis process and avoided wasting template materials. Brunauer–Emmett–Teller and XPS analysis demonstrated that NPC presented a large specific surface area (523.2 m2/g) and exhibited a high edge-nitrogen doping level of 5.19 at%, which improved K+ adsorption and intercalation capabilities. As a result, the NPC anode displayed a capacity of 315.4 mA h g−1 at 0.1 A g−1 and a capacity of 189.1 mA h g−1 at 5 A g−1 over 2,000 cycles. The assembled NPC//CMK-3 PIHC delivered a high energy density of 71.1 W h kg−1 with only 0.0025% capacity decay per cycle at the power density of 771.9 W kg−1 over 8,000 cycles.

Read the full paper:

Zhen Pan et al, A High-Concentration Edge-Nitrogen-Doped Porous Carbon Anode via Template Free Strategy for High-Performance Potassium-Ion Hybrid Capacitors, Energy Material Advances (2024). DOI: 10.34133/energymatadv.0080