Researchers from University of Maryland, USA published their research on stabilisation of permalloy nanoparticles for syringe printable inductors. The article published by Journal of Magnetism and Magnetic Materials introduces inductor syringe printing, as additive manufacturing technique with possibility for printing filaments consisting of different materials on a single tool.

Abstract

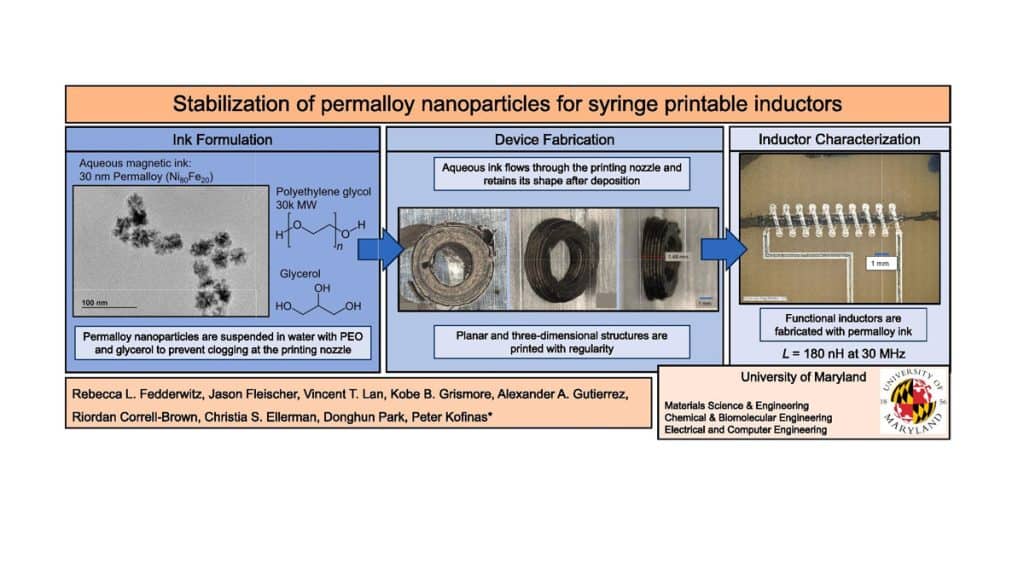

Additive manufacturing has the potential to fabricate custom parts with complex shapes. For syringe printing, there is a possibility for printing filaments consisting of different materials on a single tool. Additively manufactured electronics is a major field of investigative research, where filaments contain nanoparticles to tailor properties, such as metal to improve magnetic permeability.

This study investigates syringe printing parts with high magnetic permalloy (Ni80Fe20) nanoparticle content (>35 vol%) and the properties of inductors printed from these inks.

Two different metal alloy particle sizes of 250 nm and 30 nm are synthesized to observe the effect of particle size on stability. Zeta potential and settling behavior are observed to discern how coating procedures enhance particle stability in water. Permalloy nanoparticle inks are concentrated with polyethylene glycol (PEG) to increase viscosity and glycerol to decrease evaporation rates while printing.

It is found that PEG and glycerol stabilize 30 nm permalloy nanoparticles in addition to increasing ink viscosity. Permalloy nanoparticle inks are printed into toroid shapes demonstrating the feasibility of fabricating useful three-dimensional magnetic structures. These inductors exhibited an inductance of 180 nH at 30 MHz.

Introduction

Additive manufacturing opens the possibility of printing custom parts with complex shapes. Advancements are being made to improve accuracy and resolution, as well as expand the materials that can be printed. It is of interest to create a single tool that prints multiple material filaments, simplifying the fabrication of prototypes. A common type of 3D printing is syringe printing, which is done using a filament that is liquid during extrusion but solidifies after deposition. Typically, this is accomplished using thermoplastic resin that when heated becomes molten and solidifies again after cooling. Recent efforts have been made to include metal or ceramic particles in these resins to further tailor the properties of the materials printed, such as including ceramic particles for improved dielectric properties, conductive particles for electrical properties, or magnetic particles for magnetic properties [1]. Magnetic composite filaments are the least explored of the three mentioned and have the potential for being used for a wide array of applications, such as for microrobotics, medical devices, actuators, generators, transformers, magnetic shielding devices, magnetic recording devices, and inductors.

One of the greatest challenges of printing magnetic composites is accomplishing a high enough particle loading to produce a strong magnetic response for the additively manufactured part to be competitive with traditional magnet fabrication methods [7]. Magnetic particles embedded in a polymer feedstock is the most studied approach to printing magnetic composites, using thermoset polymers typically used for fuse deposition method printing. Ceramic particles are a common additive, with Palmero et al. mixing MnAlC particles in polyethylene at a final particle loading of 72.3 wt% (31.5 vol%) [8]. In another study, permalloy (NiFe) nanoparticles were mixed into polydimethylsiloxane at 50 wt% (1.1 vol%) and printed into an inductor using silver traces [9]. Using stereolithography, hard magnet NdFeB-Fe3O4 nanoparticles are printed in UV curable resin at 20 wt% particle loading for transformer applications [10]. Soft magnetic Ni81Fe19 was blended in polydimethylsiloxane (PDMS) and polyborosiloxane (PBS) binder up to 36 vol% and automatically pipetted, spin coated, or screen printed to create magnetic field sensors [11]. In all these ink formulations, magnetic content was limited by the high viscosity of the polymer binder.

This study investigates syringe printing of high magnetic nanoparticle content parts using permalloy (Ni80Fe20) nanoparticles, a commonly used magnetic material for inductor applications due to its high permeability. Two different particle sizes of 250 nm and 30 nm were synthesized to observe the effect of particle size on stability. Syringe printing of colloidal inks has been demonstrated for ceramic systems using polyelectrolytes as a stabilizer [12]. The charge provided by adsorbed polyelectrolytes creates an electrostatic repulsion that isolates particles in aqueous solution and prevents aggregate formation [13]. In this study, we explore the use of polyelectrolytes with varying charge groups in an attempt to coat and stabilize the permalloy nanoparticles. The use of silica as a coating was also explored as an intermediate layer between permalloy nanoparticles and polyelectrolytes in an attempt to stabilize them. Histidine has also been shown to have an affinity to nickel and its function as a stabilizer for permalloy nanoparticles was explored [14]. Zeta potential was measured to discern a change in surface charge after the various coating procedures. Settling behavior was documented to perceive the success of attempted coating procedures on particle stability in water. Aqueous permalloy nanoparticle inks were made by adding synthesized particles with polyethylene glycol to increase viscosity and glycerol to decrease evaporation rates while printing. The roles of PEG and glycerol on the stability of permalloy nanoparticles were also examined. Finally, permalloy nanoparticle inks were printed into toroid shapes to exhibit its viability in fabricating three-dimensional magnetic structures as well as being manufactured into inductors whose electrical properties are dependent on using permalloy nanoparticle magnetic ink as the core.

Materials Used

Hydrous nickel chloride, hydrous ferrous chloride, sodium hydroxide, propylene glycol, potassium tetrachloroplatinate (K2PtCl4), citrate, tetraethylorthosilicate (TEOS), ammonium hydroxide (NH4OH), acetone, ethanol, DI water, poly(acrylic acid) (PAA, Darvan), poly allylamine hydrochloride (PAH), polystyrene sulfonate (PSS), L-histidine, polyethylene glycol (PEG, 30 k MW), glycerol, potassium nitrate, silver nanoparticle ink (DOWA), mercapto ester UV and thermally curable dielectric adhesive.

Small versus large diameter permalloy

Permalloy nanoparticles were synthesized into two sizes, 30 nm, and 250 nm in diameter. VSM magnetic hysteresis measurements show that the larger diameter nanoparticles have a higher magnetic saturation of 0.59 T and a higher coercivity of 14 kA/m than the small diameter permalloy nanoparticles which have a magnetic saturation of 0.15 T and a coercivity of only 0.16 kA/m.

Conclusion

Permalloy nanoparticles with a 30 nm diameter were synthesized, stabilized, and concentrated into a syringe printable ink to be made into an inductor core and characterized as an inductor.

A series of experiments were performed using various coating techniques to ultimately discover that the same polymer used to enhance viscosity also successfully stabilizes the particles in water.

The article reference:

Rebecca L. Fedderwitz, Jason Fleischer, Vincent T. Lan, Kobe B. Grismore, Alexander A. Gutierrez, Riordan Correll-Brown, Christia S. Ellerman, Donghun Park, Peter Kofinas,

Stabilization of permalloy nanoparticles for syringe printable inductors, Journal of Magnetism and Magnetic Materials, Volume 593, 2024, 171857, ISSN 0304-8853,

https://doi.org/10.1016/j.jmmm.2024.171857