TDK blog article discusses use of power inductors in the electrification of cars including ADAS and EVs.

The automobile has been undergoing a substantial transformation in recent years. With the advent of Advanced Driver Assistance Systems (ADAS), the shift toward electric vehicles, and the growing sophistication of infotainment, cars have evolved to the point where they can be considered advanced electronic devices.

Electronic components are playing vital roles in this transformation. This article takes a close look at an electronic component that underpins the further evolution of automobiles: the power inductor for automotive applications.

Cars are rapidly turning electric

Against the backdrop of growing worldwide attention to carbon neutrality, major car manufacturers have been announcing their forays into the electric vehicle (EV) market one after another. xEVs, which refer to vehicles powered partially or entirely by batteries and motors, are leading the trend. The automotive industry is also experiencing a massive wave of technological innovation, as seen in the accelerating development of ADAS, which assist in driving using cameras and sensors to detect surrounding information, as well as in autonomous driving technologies.

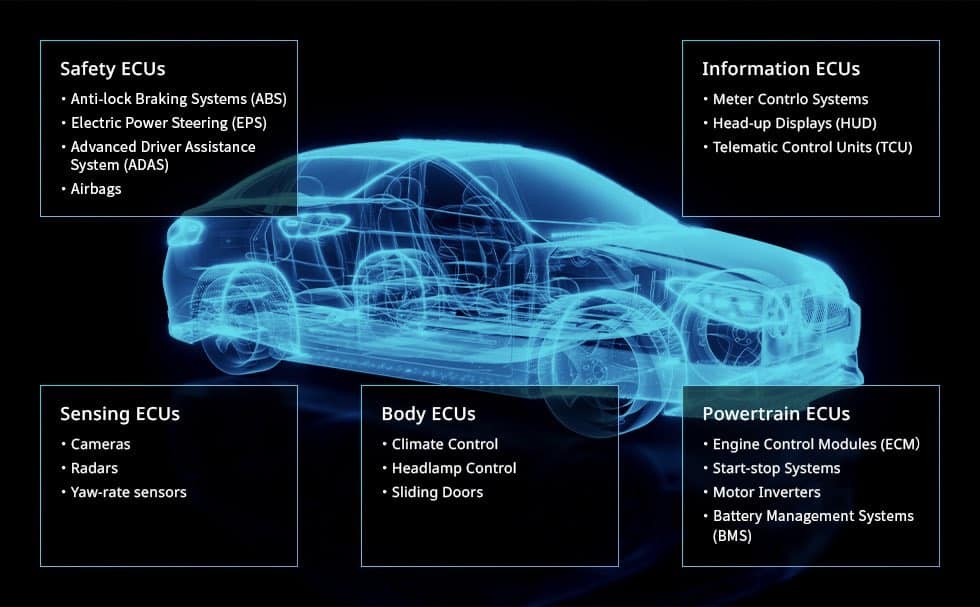

With the shift toward EVs and electronics, the number of onboard Electronic Control Units (ECUs) —computers that control engines, motors, brakes, and sensors—is rising. In fact, more than a hundred ECUs can be found in the latest cars. Cars are equipped with a variety of ECUs—those related to the powertrain, information processing, and safety—electronically controlling various vehicle functions. The number of ECUs is climbing year by year.

The role of automotive electronic components

All ECUs contain DC-DC converters that adjust the battery’s voltage to optimum levels. The power inductor is a critical component that determines the performance of these converters. Inductors pass direct current (DC) freely while behaving like resistance against alternating current (AC). When coupled with ICs that perform high-speed switching, they enable DC-DC converters to convert voltages to the required levels.

Power inductors are broadly classified into wire wound, multilayer, and thin-film types, depending on their construction. The wire wound type is characterized by its ability to carry large currents; a variety of products paired with ferrite or soft magnetic metal cores are available. The multilayer and thin-film types can be made smaller and thinner; recent years have seen their ability to handle larger currents. Because ECUs require DC-DC converters optimal for the devices they control, a broad range of power inductor products with distinct characteristics is needed.

Demand forecast for automotive power inductors

With the growing number of ECUs installed in cars, demand is surging for electronic components like inductors, capacitors, and EMC products. Global demand for automotive inductors is expected to continue expanding, approximately doubling that of 2020 by 2030.(Based on research by TDK)

TDK power inductors cover a broad range of characteristics

As xEVs and autonomous driving evolve, so do the performance requirements for automotive electronic components. Since the safety of the occupants and the surroundings is closely tied to automotive functions like autonomous driving and collision safety systems, electronic components are required to be more reliable and higher-performance than ever before. And because DC-DC converters are trending toward higher-frequency switching to reduce size and weight, power inductors must also be able to handle higher frequencies.

TDK offers an extensive lineup of power inductors designed for automotive applications to support ECUs with different inductance and current requirements based on their roles, such as for ADAS, sensors, and image processing. They deliver robust reliability by reducing the risk of failures to extreme extents, serving the sophisticated needs of autonomous driving technologies. They are also resilient against noise, a benefit that complements the increasingly higher operating frequencies of switching elements.

Hitoshi Okubo of TDK Corporation’s Magnetics Business Group discussed the strengths of TDK’s automotive power inductors. “Cars have become smarter in recent years with enhanced safety capabilities like ADAS and autonomous driving, richer infotainment features, and telematics. Because the number of electronic equipment in cars is expected to continue growing, we are looking forward to a significant expansion of the playing field for our products. At the same time, however, malfunctions in electronic equipment now have substantially adverse implications on automotive safety, so the demand for ‘zero-defect’ quality is stronger than ever. TDK offers compact, feature-rich, highly reliable inductor products by leveraging various construction methods, including wire wound, multilayer, and thin film. In particular, thin-film power inductors designed for automotive applications—which combine TDK’s proprietary thin-film and long-cultivated magnetic material technologies to produce characteristics unavailable in conventional products—offer superior properties and high reliability despite their compact size. We will continue to respond to the market’s needs by providing a wide range of products that suit customer applications.”