Researchers from Harbin University of Science and Technology, China published in Journal of Power Sources their study on energy storage performance of sandwich structure dielectric composite by BNNS/TiO2 co-doping for the high electric field capacitor.

Abstract

Dielectric capacitors are crucial for power systems and hybrid vehicles. However, the polymer film capacitor dielectric has low energy density and cannot meet the demands of high-power and energy storage systems.

The synergistic improvement of balance between dielectric constant (εr) and breakdown field strength (Eb), along with better energy storage performance, is a primary focus of this study.

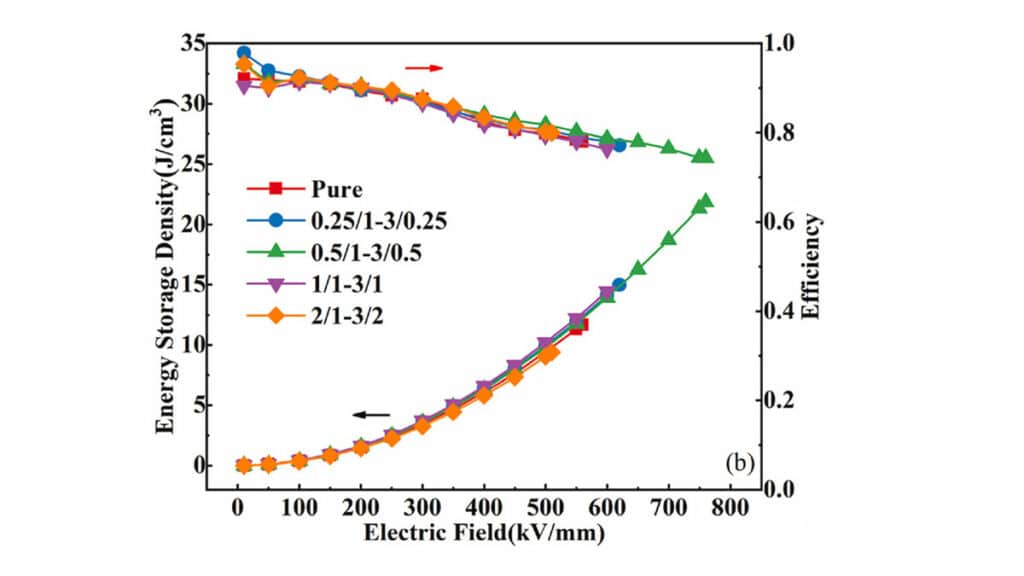

This research employs a high εr of P(VDF-TrFE-CFE) blended with linear PMMA to create a sandwich-structured composite via high-speed electrostatic spinning. Boron Nitride Nanosheets (BNNSs) for insulation and TiO2 for polarization are used as fillers, aiming to achieve polymer-based composite with large energy storage density and minimal energy loss. Results show that the sandwich-structured composite with 0.5 vol.% BNNSs in outer layer and 3 wt.% TiO2 in middle layer achieves the largest Ue of 21.8 J/cm3 at the η of 74 %. This study broadens the application of novel dielectric materials in the fields of energy.

Study Background

The surging demand for energy and ongoing depletion of traditional sources have driven efforts to broaden energy applications while enhancing utilization efficiency. The proliferation of electric vehicles and the sustained growth of portable electronic devices underscores the necessity to address energy storage and grid integration challenges. In this context, the evolution of new energy technologies is accelerating, paralleled by advancements in long-distance power transmission. With the increasing adoption of mobile devices and electric vehicles requiring substantial energy storage, the urgency for more sophisticated energy storage technologies and systems is growing. Among several promising electric memory devices, electrostatic capacitors are notably distinguished. As a result, there is a growing demand for advancements in the performance parameters and manufacturing technologies of electrostatic capacitors. The principal limitation of electrostatic capacitors lies in their low energy density, resulting from the low inherent energy capacity of storage dielectric. Therefore, enhancing the energy storage capability of dielectric material emerges as a critical step towards improving the overall performance of electrostatic capacitors.

Dielectric materials boasting high energy storage density are pivotal in contemporary electronic and electrical systems, particularly within pulse power and electronic packaging technology realms. These materials are crucial for crafting high-performance capacitors, brakes, sensors, spacecraft, and electrical stress control devices. The trend towards greater integration in high-performance electronic devices in recent years demands enhanced energy storage density from electronic materials. The goal is to identify a material system that embodies a harmonious blend of attributes, including a high εr, dielectric loss angle tangent (tanδ), Eb, and manufacturability.

Polymer nanocomposite dielectrics, characterized by their high εr, good Eb, and elevated energy density, are increasingly becoming vital in various modern electronic and electrical applications. These include pulse power systems, smart grids, and electric vehicles. The push towards more compact and lighter power modules accentuates the need for great energy density dielectrics to shrink the size and weight of dielectric capacitors. In power conversion systems like substation converter valves, capacitors play a crucial role in energy conversion. For instance, in an 800 kV system, each converter valve has a volume of 480 m3, with capacitors constituting 60 % of the weight and 50 % of the volume. Thus, enhancing the energy density of capacitors holds substantial importance for both industrial production and daily life.

Improving the εr of polymer nanocomposites often comes at the expense of reduced Eb. Merely increasing the εr does not significantly boost the energy storage density, as this density is proportional to the square of the Eb, which in turn plays a crucial role in energy storage capacity of the dielectric composite. Currently, achieving simultaneous enhancements in both εr and Eb remains a challenge for polymer composites. Nevertheless, advancements are being made with three-layer and multi-layer polymer nanocomposites, which, unlike traditional monolayer structures, offer greater flexibility in modifying the chemical composition and spatial arrangement of nano-fillers within the polymer matrix. This multilayer approach opens new avenues for developing high-performance dielectric materials.

The exceptional mechanical attributes of polymer dielectric materials, such as their flexibility and processability, present ongoing challenges in their application within large energy density capacitive devices. Consequently, recent years a surge in research efforts aimed at modifying polymer dielectrics. Scholars are exploring the enhancement of dielectric properties in both individual and composite polymer dielectrics to achieve high voltage endurance and minimal tanδ. Through dual or multiphase blending techniques, the uniform integration of multi-component materials is achieved, leveraging the strengths of each component to produce composites with superior performance. This strategy aims to develop materials with outstanding energy storage capabilities by combining and augmenting the advantages of various components.

Huang and colleagues have pioneered a three-layer structure using a scraping technique, featuring P(VDF-TrFE-CTFE) as the core layer and PMMA as the external layer. This innovative design significantly enhances the energy storage density by approximately 32 % compared to a single-layer P(VDF-TrFE-CTFE) dielectric, particularly improving impulse discharge efficiency (η). At an applied field of 480 kV/mm, the η escalated to 78 %. Similarly, Li et al. have developed a sandwich-structured composite dielectric combining PVDF with hexagonal boron nitride (BN) and barium strontium titanate nanofibers, consolidated through hot pressing technology. This composition achieved an energy storage density of 20.5 J/cm3 under a 577 kV/mm electric field. Further advancing composite material energy storage, Wang introduced a novel BaTiO3/P(VDF-HFP) nanocomposite with a sandwich structure fabricated layer-by-layer. This structure integrates a high concentration of BaTiO3 particles in the middle layer and a lesser amount in the outer layers, yielding a high εr and superior insulation. The composite material demonstrated an impressive discharge energy density (Ue) of about 26.4 J/cm3 and a η of 72 %. The above research results provide inspiration for the structural design of composite dielectrics in this work.

Polyvinylidene fluoride (PVDF) and its copolymers are at the forefront of room temperature energy storage research, owing to the high polarization strength imparted by the C-F bond and the spontaneous dipole orientation in crystal domains. Incorporating additional monomers to form binary or ternary copolymers can refine crystal domain size and lower the energy barrier in phase transitions, thus maintaining commendable Eb. Consequently, PVDF is extensively utilized in energy-related applications. The choice and compatibility of fillers with the polymer significantly influence the εr, Eb, and energy storage characteristics of composites. BN, with its high band gap, chemical inertness, and outstanding insulation, along with TiO2, known for its high εr, compatibility, corrosion resistance, low cost, and ease of large-scale production, are both highly regarded as composite fillers. Utilizing these fillers in dielectric composites addresses the trade-off between Eb and εr, enhancing the energy storage performance of the composites.

Building on prior research, this paper explores combining ferroelectric polymer P(VDF-TrFE-CFE) blends with linear poly(methylmethacrylate) (PMMA) to create a high-performance energy storage substrate. This approach aims to utilize the linear dielectric properties of PMMA to mitigate losses in P(VDF-TrFE-CFE), enhancing energy storage efficiency. Utilizing high-speed electrostatic spinning, we fabricate sandwich-structured composite dielectrics, incorporating BNNSs for insulation and TiO2 nanosheets for polarization as fillers. This research focuses on polymer-based composite dielectric materials, aiming to elevate both the εr and Eb of the composites. Through comprehensive testing and analysis of the composites microstructure and electrical properties, the varying filler content in the sandwich structure was investigated, especially, which may influence the energy storage performance of dielectric composite. This methodology involves designing a sandwich-structured composite dielectric with an insulating BNNSs-filled hybrid matrix as the outer layer and a co-doped BNNSs and TiO2 as inner layer dielectric to simultaneously adjust the εr and Eb. By varying the BNNSs content in the outer layer and maintaining a constant content of co-doped BNNSs and TiO2 in the inner layer, the optimal doping ratio of filler was identified to simultaneously achieve large εr and good Eb, further obtaining the composites with excellent energy storage performance.

Conclusion

This study investigates the sandwich structure composite incorporating TiO2 nanosheets and BNNSs as fillers in the matrix of blending with fluoropolymer P(VDF-TrFE-CFE) and PMMA, preparing a composite film.

This research focuses on the influence of varying BNNS content in the outer layer on the properties of composites, including both the good suitability and the enhancing dielectric energy storage capability. BNNS with great band-gap (∼6 eV) owning excellent insulation, with εr between 3 and 4.

Link to the full scientific paper: https://doi.org/10.1016/j.jpowsour.2024.235551