In this post, Samtec explain construction of its NITROWAVE™ coaxial cables and role of the inner layer to achieve high performance RF bandwidth.

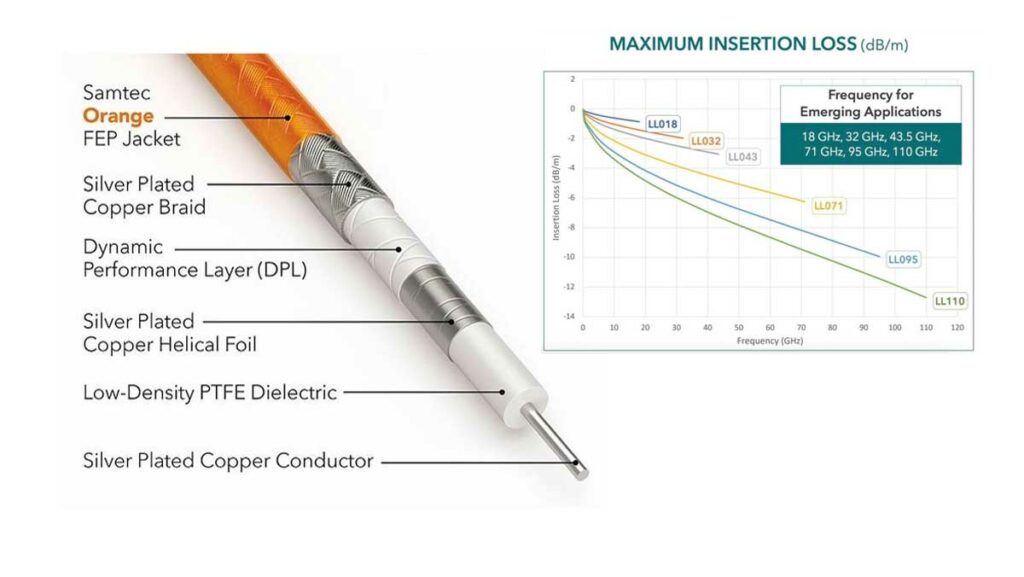

The inner layer of NITROWAVE coaxial cable, the dynamic performance layer (DPL), plays a pivotal role in its construction. NITROWAVE is Samtec’s comprehensive range of high-performance RF solutions, encompassing full cable assemblies, cable connectors, and board-level interconnects, specifically designed for microwave and mmWave applications.

Controlling the interaction between the conductor and shield is paramount in cable design, especially for high-performance cables. Achieving optimal RF performance while accommodating the cable’s requirements often necessitates a compromise. Most manufacturers employ a combination of foil tape or wrap as the inner layer and a woven braid that covers the foil.

NITROWAVE cables utilize silver-plated copper for both the foil and braid, complemented by an FEP (Fluorinated ethylene propylene) jacket in Samtec’s signature orange color. This jacket provides protection in challenging environments, particularly in the aerospace and defense industries, as well as instrumentation and computing sectors. It offers exceptional working temperature and resistance to abrasion.

However, the DPL stands out as a particularly intriguing feature of NITROWAVE. The DPL is a thin layer of PTFE strategically placed between the foil and braid shields. Despite its seemingly insignificant nature, the DPL plays a pivotal role in the NITROWAVE narrative. Its primary function is to eliminate friction between the foil and braid, ensuring the braid’s unhindered movement over the foil without causing damage. The DPL also contributes to overall reliability by wrapping around the helical foil shield, enhancing its strength during flexing. Additionally, it serves as an interface between the delicate foil and the woven braid surrounding it, thereby reducing the risk of conductive oxidation. Consequently, the cable achieves a longer flex cycle life and enhanced durability.

Enhanced Electrical Performance

The advantages of the DPL extend beyond enhanced mechanical performance. The improved physical properties also contribute to improved electrical performance. DPL provides enhanced phase stability. Phase refers to the position of a wave at a specific point in time within its cycle, which is crucial when considering how RF signals travel along cables. A phase shift is a change in the wave’s position, typically caused by external forces such as cable bending or temperature variations. Greater phase stability results in more consistent RF signals, even when the cable itself flexes.

The DPL layer also helps reduce capacitive coupling. This occurs when two separate shield layers come into close contact, acting as the plates of a tiny capacitor. Even the small electrical charges that can accumulate between the layers have the potential to generate unwanted noise, which can negatively impact signal integrity. Even the thin layer of PTFE that constitutes the DPL is sufficient to minimize this coupling and enhance overall SI performance.

NITROWAVE Applications

One challenge when discussing high-performance products like NITROWAVE and the Samtec precision RF range is that it may alienate some customers. Just as most drivers wouldn’t consider using a Rolls Royce or a Ferrari for their daily commute, designers wouldn’t use a cable with 110 GHz performance for their products.

However, a key feature of NITROWAVE is that it’s not a single product but a family of cables, each optimized for different frequencies ranging from 18 GHz to a maximum of 110 GHz. These cables were carefully selected based on extensive studies of customer requirements, with each cable designed to deliver the lowest possible insertion loss within its specific frequency range.