Source: Phys.org news

January 8, 2018, Zhejiang University. Aluminum-ion batteries (AIB) have significant merits of low cost, non-flammability, and high-capacity metallic aluminum anodes based on three-electron redox properties. However, due to its inadequate cathodic performance, especially in terms of capacity, high-rate capability, and cycle life, AIB still cannot compete with Li-ion batteries and supercapacitors.

To address these issues, a research team led by GAO Chao, a professor in ZJU’s Department of Polymer Science and Engineering, has proposed a “trihigh tricontinuous (3H3C) design” to achieve the ideal graphene film (GF-HC) cathode with excellent electrochemical performances.

The ordered assembly of graphene liquid crystal leads to a highly oriented structure satisfying requirement. High temperature annealing and concomitant gas pressure contribute to high-quality yet high channeling graphene structure simultaneously. Owing to this targeted 3H3C design, the resulting aluminum-graphene battery (Al-GB) achieves an ultralong cycle life (91.7 percent retention after 250,000 cycles), unprecedented high-rate capability (111 mAh g−1 at 400 A g−1 based on the cathode), a wide operation temperature range (−40° to 120°C), unique flexibility, and nonflammability.

Targeted 3H3C design is proposed to essentially resolve the “short slab” cathode problem of AIB, achieving high-performance Al-GBs with record rate capability, cycle life, and operation temperature range among various kinds of rechargeable batteries. Together with future innovation in low-cost electrolyte, the emerging Al-GB provides a highly competitive choice for the capacitor-dominant high-power density energy storage system. In addition, the 3H3C design philosophy can also be extended to other electrode materials to effectively improve their electrochemical performances for practical electric power applications.

Relevant findings appeared on the December 15 issue of Science Advances.

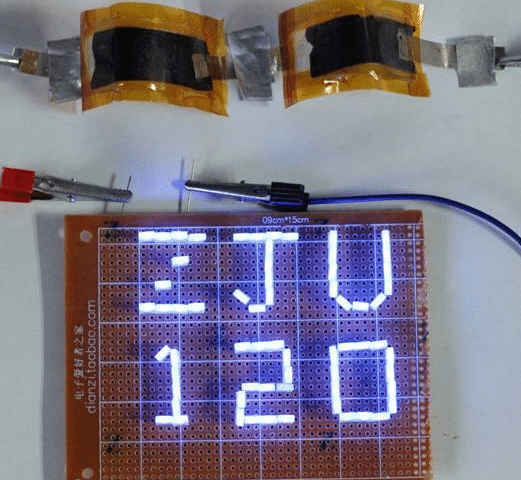

featured image: LED lights powered by ultrafast batteries designed by ZJU scientists. Credit: Zhejiang University