This article provides basic overview of shunt resistors, its typical characteristics, types and applications.

Introduction

Shunt resistors are precision resistive components widely used in electrical and electronic circuits to measure current. By providing a low-resistance path parallel to the measurement device, the shunt resistor generates a small voltage drop proportional to the current flowing through it. This voltage drop can be accurately measured and converted into a current reading. Shunt resistors are essential for power monitoring, battery management systems, and many industrial applications requiring accurate current sensing with minimal power loss.

Key Points

- Shunt resistors operate by producing a voltage drop proportional to current based on Ohm’s law.

- They must have very low and stable resistance to minimize power dissipation and maintain measurement accuracy.

- Accuracy depends on resistive material, manufacturing precision, temperature coefficient, and power rating.

- Common materials include metal film, metal foil, and wirewound types, each with specific trade-offs.

- Applications range from energy meters and motor drives to battery management and power supplies.

What Is a Shunt Resistor?

A shunt resistor is a low-resistance component placed in series with a load to measure current. When current flows through the resistor, it generates a small voltage drop proportional to the current, as described by Ohm’s Law:

V = I × R

where:

- V is the voltage drop across the shunt resistor (volts)

- I is the current through the resistor (amperes)

- R is the resistance value of the shunt resistor (ohms)

By measuring this voltage drop and knowing the precise resistance value, the current can be calculated with high accuracy. Shunt resistors are typically made from materials with low temperature coefficients, such as manganin or constantan, to ensure stability over a wide range of operating conditions.

The voltage drop V is measured using a high-precision voltmeter or an analog-to-digital converter (ADC) in combination with a microcontroller or digital signal processor. The known resistance value R allows calculation of the exact current I flowing in the circuit.

Characteristics and Design Considerations

Key parameters for selecting and designing shunt resistors include:

- Resistance value: Usually very low, ranging from micro-ohms to milliohms, to minimize power loss and heating.

- Power rating: Must withstand the power dissipation, calculated as P=I2R.

- Temperature coefficient of resistance (TCR): Lower TCR ensures stable resistance across temperature changes and improves accuracy.

- Material type: Metal foil resistors offer low TCR and precise values; metal film resistors are common for general use; wirewound resistors are robust but may have inductance.

- Physical size and thermal management: Appropriately sized resistors avoid excessive temperature rise that can affect resistance stability.

Applications of Shunt Resistors

Shunt resistors are crucial components in a variety of applications:

- Power Supplies and Inverters: Used for monitoring load currents in DC and AC power supplies, enabling precise regulation and protection.

- Battery Management Systems (BMS): Provide accurate charge and discharge current measurements in electric vehicles and renewable energy storage, ensuring battery health and safety.

- Overcurrent Protection: Detects when current exceeds set thresholds to trigger protective shutdowns, preventing damage to circuits and devices.

- Energy Meters: Measures consumption in residential and commercial electricity metering systems based on current flow monitored via shunt resistors.

- Motor Control: Enables feedback control by measuring motor current to optimize performance and efficiency.

- Testing and Laboratory Equipment: High-precision shunts are used in calibration and test instruments where accurate current measurement is critical.

- Industrial Automation: Facilitates real-time current sensing in automated manufacturing processes for monitoring and control.

Shunt Resistors and Their Importance in Measuring Current

In modern electronics and power systems, accurate current measurement is essential for efficiency, safety, and control. One of the most reliable and cost-effective methods for current sensing is the use of shunt resistors. These precision components play a pivotal role in power monitoring systems across industries—from automotive and renewable energy to industrial automation and consumer electronics.

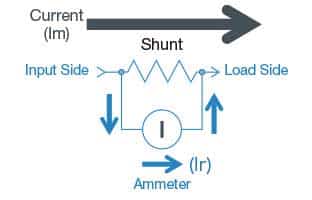

- Im: Total circuit flowing to the circuit

- Ir: Current flowing to the ammeter

- r: Internal electrical resistance of the ammeter

- R: Shunt (divide) resistance

For example, the total current (Im) flowing to the upper circuit can be expressed by the following equation.

Im = Ir + Ir × (r / R) = Ir × (1 + r / R)

As a result, the ratio of total current flowing through the circuit with the current flowing through the ammeter:

Im / Ir = (1 + r / R)

Why Use Shunt Resistors for Current Measurement?

- Precision: Shunt resistors offer highly accurate current sensing when paired with precision ADCs or instrumentation amplifiers.

- Cost-Effective: Compared to Hall effect sensors or current transformers, shunt resistors are inexpensive and compact.

- Wide Range: Suitable for both low-current microampere measurements and high-current industrial applications.

- Integration: Easily embedded into PCBs and compatible with digital monitoring systems.

Applications in Power Monitoring Systems

Shunt resistors are integral to power monitoring systems, enabling real-time tracking of current, power consumption, and energy usage. Key applications include:

- Battery Management Systems (BMS): Monitoring charge/discharge currents in EVs and portable electronics.

- Smart Meters: Measuring household or industrial energy consumption with high resolution.

- Power Supplies: Ensuring load regulation and overcurrent protection in DC/DC converters and inverters.

- Renewable Energy: Tracking current flow in solar inverters and wind turbine controllers.

Design Considerations

When selecting a shunt resistor, engineers must consider:

- Resistance Value: Low enough to minimize power loss, but high enough to produce a measurable voltage.

- Power Rating: Must handle the expected current without overheating.

- Temperature Coefficient: Affects accuracy under varying thermal conditions.

- Mounting Style: Surface-mount vs. through-hole depending on application and thermal management.

Shunt resistors are indispensable tools in the realm of current measurement and power monitoring. Their simplicity, precision, and adaptability make them a cornerstone of modern electronic design. As energy efficiency and system intelligence become increasingly critical, the role of shunt resistors will only grow in importance.

Quick Tip

For high-side current sensing, consider using a differential amplifier or dedicated current-sense IC to accurately measure the voltage across the shunt without disturbing the ground reference.

Manufacturing Techniques

The performance of shunt resistors depends heavily on their manufacturing processes. Common manufacturing techniques include:

- Metal Foil Technology: Involves bonding a thin metal foil with precision resistivity to a ceramic substrate. The process allows highly stable and low TCR resistors with excellent long-term reliability. The foil is carefully trimmed to achieve target resistance values and calibrated for accuracy. This method is preferred in precision applications.

- Metal Film Deposition: Metal films are sputtered or evaporated onto ceramic bases. The thickness and patterning of the film is controlled to set resistance. These resistors offer moderate precision and stability and are widely used for general purposes.

- Wirewound Construction: A resistive wire (often nickel-chrome) is wound tightly on a ceramic core. This type can handle high power ratings but may introduce inductance, limiting use in high-frequency circuits. Modern wirewound resistors employ special winding techniques to reduce inductance for certain applications.

- Laser Trimming: Post-manufacture, laser trimming is used for fine-tuning resistance values. This ensures very tight resistance tolerances and improves accuracy, especially important in precision shunts.

- Encapsulation and Coating: Resistors are coated and encapsulated to protect against moisture, oxidation, and mechanical damage. The quality of encapsulation affects stability and lifespan, particularly in harsh environments.

- Quality Control and Testing: Manufacturing includes rigorous testing for resistance accuracy, TCR, power rating, and thermal stability. Automated test setups provide traceability and ensure compliance with international standards.

Example Datasheet Specifications

| Parameter | Value | Notes |

|---|---|---|

| Resistance | 0.010 Ω (10 mΩ) | Typical low-value precision shunt |

| Power Rating | 5 W | Continuous dissipation capability |

| Resistance Tolerance | ±0.5% | Manufacturing accuracy |

| Temperature Coefficient (TCR) | ±10 ppm/°C | Low TCR for stable operation |

| Operating Temperature Range | -55 °C to +150 °C | Standard industrial range |

| Maximum Overload | 10x rated power for 5 seconds | Handling short transient currents |

| Inductance | <10 nH | Crucial for high-frequency applications |

Comparison of Typical Shunt Resistor Types

| Type | Resistance Range | Power Rating | TCR (ppm/°C) | Inductance | Typical Applications |

|---|---|---|---|---|---|

| Metal Foil | 1 μΩ – 100 mΩ | 0.5 to 10 W | ±5 to ±20 | Very Low (~1-10 nH) | Precision current sensing, Battery management |

| Metal Film | 1 mΩ – 1 Ω | 0.25 to 5 W | ±50 to ±100 | Low | General current measurement, Instrumentation |

| Wirewound | 0.1 Ω – 10 Ω | 5 to 50 W+ | ±100 to ±250 | Moderate to High | High power circuits, Motor drives |

Limitations and Challenges

Shunt resistors, while effective, have some limitations:

- Power dissipation can cause self-heating, altering their resistance and affecting measurement accuracy.

- Low resistance values require sensitive voltage measurement circuits due to small voltage drop.

- Inductive and capacitive parasitics in certain types (e.g., wirewound) can interfere with high-frequency measurements.

- Proper layout and wiring are critical to minimize measurement errors caused by contact resistance and lead inductance.

Conclusion

Shunt resistors remain fundamental for precise current sensing due to their simplicity, reliability, and proven technology. Their accuracy depends heavily on material selection, design parameters, and proper application. Advances in materials and manufacturing continue to improve performance, enabling their use in increasingly sensitive and demanding electronic systems for industrial, automotive, and consumer applications.