Researches at Colorado State University, CO, USA and Rice Lake Weighing Systems, WI USA published an article entitled “Characterization of resistors created by fused filament fabrication using electrically-conductive filament” on evaluation of 3D additive prints resistors using electrically conductive carbon black and graphene-based filament.

Desktop fused filament fabrication (FFF) printers (3D printers) are ubiquitous rapid prototyping (RP) and additive manufacturing (AM) devices used by small and large companies as well as by hobbyists. Their attractiveness stems from the inexpensive hardware, inexpensive plastic materials, affordable CAD environments, and short training times. This research explores design of resistors created by the FFF printing process using commercially available electrically-conductive carbon black and graphene-based filament.

3D printed resistors are designed, constructed, and characterized. A number of tests are performed resulting in a set of build recommendations. With this novel capability to directly create electrical components integrated into 3D printed physical objects designers can envision and 3D print new and/or improved devices with embedded electronics, which they could not do before.

Summary and Conclusions

Creating 3D printed objects with embedded 3D printed electronic circuits is a reachable goal for FFF 3D printers using electrically-conductive filament. In this work, the simplest electrical passive element, the resistor, is addressed.

Due to the nature of the FFF process, the resistors created using graphene-based filament are non-homogeneous devices, thus their resistivity varies depending on their build orientation and FFF process parameters. An FFF printer, with two extruders and associated software was used to build a number of resistors for their characterization.

Resistor expansions in x axis resulted in increased resistivity, but this increase was not linear. For z-axis expansions, the resistivity increase was mostly linear. The resistivity vs. length graph for y-axis expansion exhibited a minimum value in the middle of the test range.

This work provides a number of guidelines and recommendations for designing 3D printed resistors as parts of 3D printed objects that contain electrical circuits.

read the abstract and download full article in pdf on the link below.

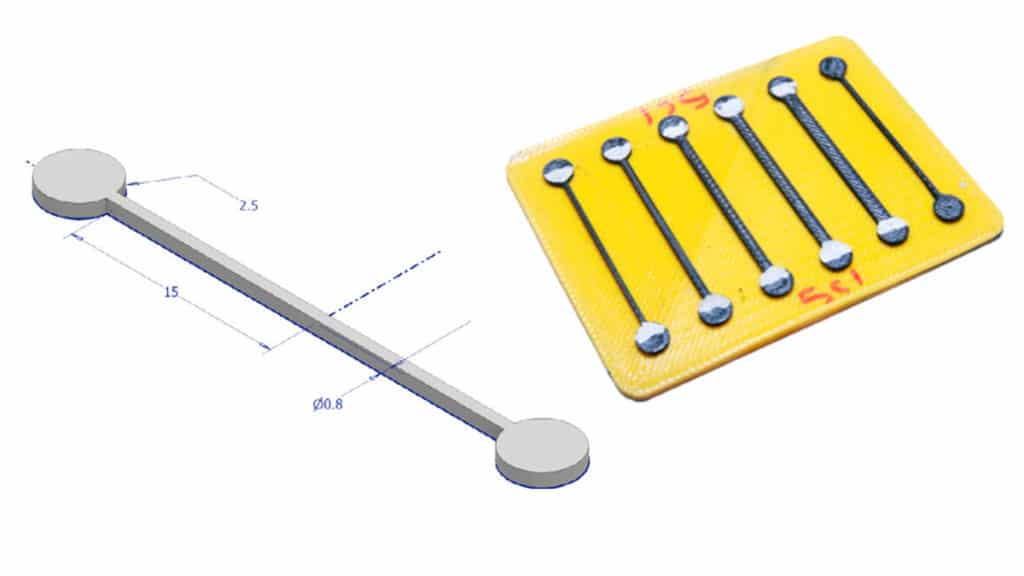

featured image: resistor test sample design (mm) and 3D printed sample of an x-axis expansion testbed; source: Science Direct article