Researchers from China published article “Effect of thermal stress on the life of DC link capacitors for smart grid” in Journal Nature.

Introduction:

The study explores how thermal stress impacts the lifespan of DC link film capacitors (DCLC), which are crucial components in smart grids. The capacitors use biaxially oriented polypropylene (BOPP) film, known for its excellent electrical properties and low dielectric loss. The focus is on the breakdown strength and life aging of DCLCs under various heat setting temperatures (HSTs) and operating temperatures.

Thermal stress significantly impacts the lifespan of DC link capacitors (DCLC), vital in power electronics within smart grids. This study investigates the thermal stress mechanisms affecting DCLC, focusing on heat setting temperatures (HSTs) and operating temperature (OT). Experiments revealed that increased HST enhances breakdown strength and lifespan, while higher OT deteriorates both, emphasizing thermal stress management in DCLC design for improved performance.

Key Components and Mechanism:

- DCLC Construction: The DCLCs in the study comprise a shell, terminal, elements, connecting copper bar, insulating parts, and filled insulating medium. Cylindrical elements are used, wrapped with metallized polypropylene films.

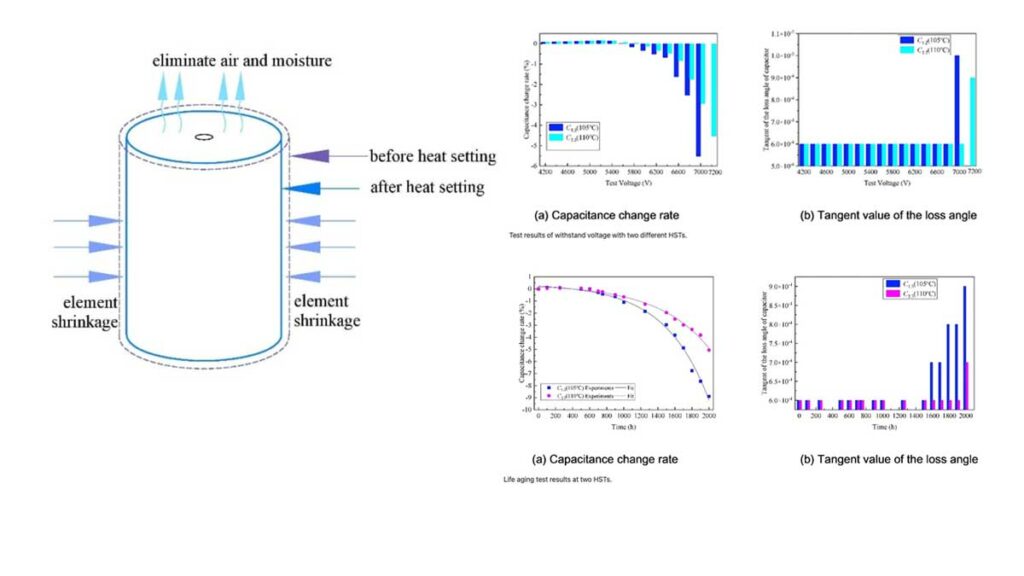

- Heat Setting Process (HSP): The HSP involves placing the elements, applying heat, cooling, and inspection. This process removes residual thermal stress, leading to irreversible thermal shrinkage, improving breakdown field strength, and reducing moisture content.

Experimental Methods:

- Sample Preparation: DCLCs with different HSTs (105 °C and 110 °C) were prepared. Samples were measured for diameter changes, withstand voltage, and life aging.

- Element Diameter Measurement: Higher HST results in larger diameter changes due to the shrinkage of BOPP film.

- Withstand Voltage Test: The breakdown strength of DCLC was tested by applying increasing voltage until failure.

- Life Aging Experiment: Performed at various temperatures (55 °C, 70 °C, 75 °C, 80 °C, and 85 °C) and at 1.4 times the rated voltage (1.4 UₙDC).

Findings:

- Effect of HST:

- Increasing HST by 5 °C improved breakdown strength by 2.86% (from 7,000 V to 7,200 V) and increased life span from 1,500 hours to 1,700 hours.

- The initial increase in capacitance due to HSP was followed by a decrease over time.

- Higher HST enhances molecular arrangement and crystallinity, reducing ion movement, increasing insulation resistance, and prolonging the life of DCLC.

- Effect of Operating Temperature:

- Higher temperatures led to a significant reduction in lifespan (from 4,200 hours at 55 °C to 500 hours at 85 °C).

- Capacitance change was more pronounced at higher temperatures.

- Lifespan analysis showed that increasing operating temperature adversely affected DCLC performance, reducing breakdown strength and increasing dielectric loss.

Conclusion:

The study concluded that the lifespan of DCLC could be significantly enhanced by optimizing HST and reducing operating temperatures. These findings are pivotal for the industrial production of high-performance DCLCs for high-power applications in smart grids. The research underlines the importance of thermal stress management in extending the durability and reliability of capacitors used in power electronics.

Read the full paper:

Sun, XW., Qiao, Y., Li, YD. et al. Effect of thermal stress on the life of DC link capacitors for smart grid. Sci Rep 15, 3968 (2025). https://doi.org/10.1038/s41598-025-88522-2, DOI https://doi.org/10.1038/s41598-025-88522-2