This article provides a comprehensive technical framework overview for electrolyte selection in supercapacitor design.

Introduction

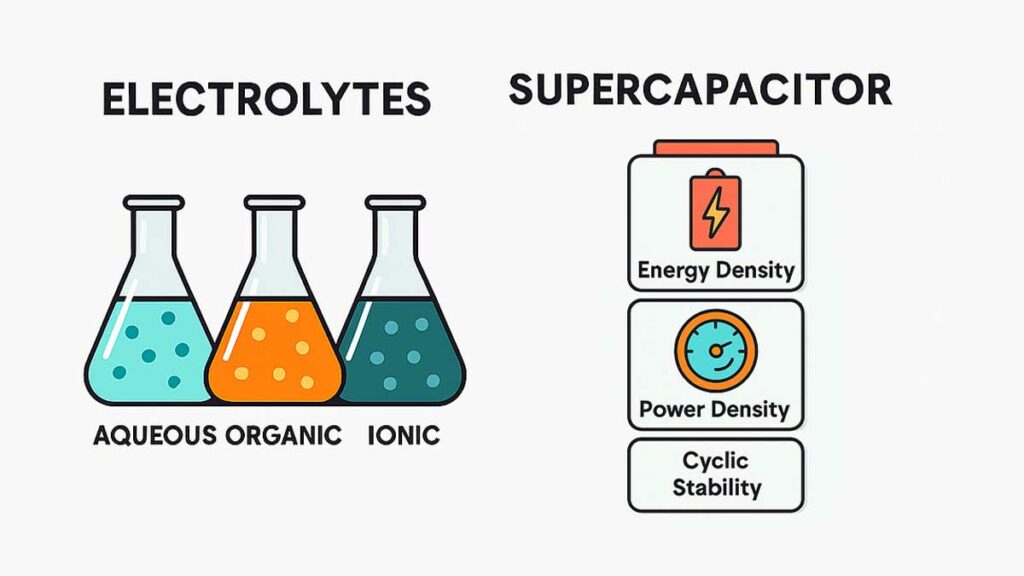

Supercapacitors are at the forefront of next-generation energy storage, offering rapid charge–discharge cycles, high power density, and long operational lifetimes. While electrode materials often receive the spotlight, the electrolyte is equally decisive. It not only defines the electrochemical stability window (ESW) but also governs ion transport, interfacial dynamics, and long-term reliability.

Key Points

- Electrolyte choice dictates both energy density and power density through its ESW and ionic conductivity.

- Ion size, solvation, and mobility determine pore accessibility and capacitance efficiency.

- Electrolyte–electrode compatibility influences degradation, self-discharge, and cycle life.

- Hybrid and redox-active electrolytes represent a frontier for enhancing performance beyond traditional limits.

Electrolyte Fundamentals and Governing Equations

The energy density of a supercapacitor is expressed as:

where C is the capacitance and V is the maximum operating voltage. Since V is capped by the electrolyte’s ESW, extending this window is a direct route to higher energy density. The power density is approximated by:

where R is the equivalent series resistance (ESR), heavily influenced by electrolyte conductivity and viscosity. Thus, the electrolyte simultaneously governs both energy and power performance.

Aqueous Electrolytes: High Conductivity, Narrow Window

Aqueous electrolytes excel in ionic conductivity (10–100 mS/cm), enabling ultrafast charge–discharge. However, water decomposition limits the ESW to ~1.23 V. Recent strategies to extend this include:

- “Water-in-salt” electrolytes: Highly concentrated LiTFSI solutions suppress water activity, extending ESW to ~3 V.

- pH-neutral electrolytes: Safer and less corrosive, though with reduced ionic mobility.

- Hybrid aqueous systems: Combining salts with additives to stabilize electrode interfaces.

Organic Electrolytes: Expanding Voltage

Organic solvents such as acetonitrile (AN) and propylene carbonate (PC) allow ESWs up to 2.7–3 V, significantly boosting energy density. However, their ionic conductivity is typically one order of magnitude lower than aqueous systems. Key challenges include:

- High flammability and toxicity (especially AN).

- Viscosity and ion pairing effects reducing mobility.

- Electrode passivation and SEI (solid electrolyte interphase) formation, which can both stabilize and hinder performance.

Ionic Liquids: Stability at a Cost

Ionic liquids (ILs) offer ESWs up to 4 V, thermal stability, and negligible vapor pressure. Their drawbacks are high viscosity and cost, which limit ion mobility and scalability. Recent advances include:

- Binary IL mixtures: Reducing viscosity while retaining wide ESW.

- Functionalized ILs: Tailoring cation/anion structures for specific electrode compatibility.

- IL–organic hybrids: Balancing conductivity and voltage stability.

Solid and Quasi-Solid Electrolytes

Solid-state electrolytes, including polymer gels (e.g., PVA-KOH, PEO-LiClO4), provide mechanical stability, safety, and flexibility. They are particularly attractive for wearable and flexible electronics. However, their ionic conductivity (10-4–10-3 S/cm) is significantly lower than liquid systems. Nanofiller incorporation (e.g., SiO2, TiO2) and ionic liquid doping are promising strategies to enhance conductivity.

Electrode–Electrolyte Interactions

The electrolyte’s role extends beyond bulk transport to interfacial phenomena:

- Ion size vs. pore size: Micropores (<1 nm) require desolvation of ions, which can limit kinetics but increase capacitance.

- Solvation dynamics: Strongly solvated ions (e.g., Li+ in water) face higher desolvation barriers.

- Specific adsorption: Certain ions (e.g., SO42-) interact strongly with carbon surfaces, altering double-layer structure.

- Electrochemical stability: Side reactions at the interface can lead to gas evolution, electrode degradation, or SEI formation.

Comparative Performance Table

| Electrolyte Type | Conductivity (S/cm) | ESW (V) | Advantages | Limitations |

|---|---|---|---|---|

| Aqueous | 0.1–1.0 | 1.0–2.0 | High conductivity, low cost | Narrow voltage window |

| Organic | 0.01–0.1 | 2.5–3.0 | Wide voltage, higher energy density | Flammable, toxic, lower conductivity |

| Ionic Liquids | 0.001–0.01 | 3.5–4.0 | Stable, non-volatile | Viscous, expensive |

| Solid/Quasi-Solid | 10-4–10-3 | 1.5–3.0 | Safe, flexible, stable | Low conductivity |

Emerging Directions

The frontier of electrolyte research is moving toward multifunctional and hybrid systems:

- Redox-active electrolytes: Incorporating redox couples (e.g., I–/I3–, quinones) to add pseudocapacitance and boost energy density.

- Deep eutectic solvents (DES): Low-cost, tunable alternatives to ILs with wide ESWs.

- Hybrid aqueous–organic systems: Combining safety and conductivity of water with voltage stability of organics.

- Interface engineering: Surface functionalization of electrodes to optimize ion adsorption and suppress side reactions.

Conclusion

Electrolytes are not passive media but active enablers of supercapacitor performance. From aqueous to organic, ionic liquid, and solid-state systems, each class offers unique trade-offs between conductivity, voltage, safety, and cost. Future breakthroughs will likely emerge from hybrid systems and interface engineering, where electrolyte chemistry is co-designed with electrode architecture. By integrating these deeper insights, researchers and engineers can push supercapacitors toward higher voltages, safer operation, and broader application in the global energy transition.

Further references:

- Electrolyte selection for supercapacitive devices: a critical review, https://doi.org/10.1039/C9NA00374F

- A review on electrolytes for supercapacitor devices, https://doi.org/10.1007/s43939-023-00065-3