Miniaturization has long been “en vogue” when it comes to multi-layer ceramic chip capacitors. But downsizing is no trivial process, especially given that there are many marginal conditions to be considered. Digital tools can help, but relying on these can often cause you to lose perspective of key technical issues. Read more in article published by Rutronik.

Multi-layer ceramic chip capacitors (MLCCs) are small and thus useful for miniaturization. But it is also important to consider aspects such as ESD protection, EM interference and heat management, as well as the typical characteristics and the drift that goes hand in hand with these. Digital tools are increasingly being used to make the process of selecting components easier. Even so, developers still need to keep all of the aforementioned aspects in view to be able to achieve their objective quickly and avoid unnecessary re-design work.

First of all, it is recommended to not simply fall back to existing value combinations of MLCCs when downsizing-especially in terms of capacitance (C value) and voltage-but instead to base decisions on the actual needs of the application and even on the function of the individual components. Ideally, the preferred versions of the suppliers should be considered. Alongside the C value and voltage, other important values include impedance and ESR (equivalent series resistance).

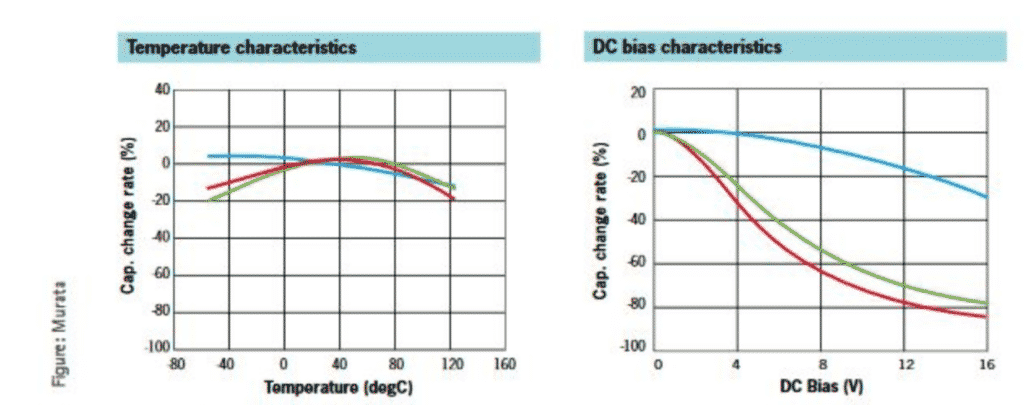

Especially with “hi-caps”, which are MLCCs with C values measured in µFs, the DC bias is also a factor to be taken into consideration. DC bias is an effect that reduces capacitance depending on the applied DC voltage. It can drop to as low as around 20% of the nominal value at the rated voltage, depending on the component, so it is essential to be aware of your absolute minimum C value during operation.

Figure 1 shows a number of examples of DC bias curves. They show that the DC bias rate is much higher with smaller components.

Another factor of influence on DC bias is operating temperature, as illustrated by the graph in Figure 2, which shows that for smaller constructions with higher nominal values, the remaining capacitance over DC bias and temperature is far above that of larger constructions with lower nominal values.

When grading nominal C values, developers should base their choices on the base guide values (Tables 1 to 3), which means that they should ideally only use the “preferred” values with the standard tolerances. In fact, the Z5U and Y5V ceramic types should be left well alone, as they are increasingly being discontinued, and some actually already are discontinued.

In addition to the issue of DC bias, Class 2 ceramic capacitors (such as X7R, X5R) also have temperature drift and aging to consider.

Temperature drift can be relatively easily determined using the table (Table 4 and Figure 3). It shows, for example, that an X5R MLCC has a predictable temperature drift of ±15% in a temperature range of -55°C to +85°C.

MLCCs also age

Aging causes MLCCs to lose capacitance over time. The loss is between around 1% and 6% per logarithmic decade, which means after 1 hour, after 10 hours, after 100 hours, and so on. As a result, the higher the C values and the thinner the internal layers of an MLCC, the more susceptible the MLCC will be to aging. That said, compared to the effects of DC bias and temperature drift, aging is basically a negligible factor, although it can play a key role when measuring C values for testing tolerances.

Unlike with living beings, MLCC aging is a reversible process. Appropriate heat treatment allows the effect to be reversed. The components are usually exposed to +150°C for an hour, then allowed to rest for 24 hours. Soldering also enables “de-aging”. See Figure 3.

Looking at the various C value drifts overall, it becomes apparent that it is not advisable to use Class 2 capacitors with a limited nominal tolerance range of ±5% instead of the standard tolerance range of ±10%-even if some suppliers still offer and deliver this. The result is pointless debates on adherence to tolerance ranges. During measurements, compliance with requirements regarding measuring devices and measurement conditions is frequently inadequate. For example, the measurement voltage, usually with a defined effective value of 1.0V, drops during the measurement, causing the displayed capacitance value to be too low.

Better to Leave some breathing space with voltage requirements

The specified voltage is usually a DC voltage-even if it is not explicitly labeled as such. If the value is an AC voltage, this will be declared accordingly (e.g. “250V AC”). Additional details and information, for example relating to ripple current, peak-to-peak etc. are usually provided by suppliers in their detailed data sheets or in their specification/application information. It is important to note here though that MLCCs that have the same C value but a higher dielectric strength (regardless of predictability or error rate aspects) tend to have thicker interior layers, which results in a less pronounced DC bias.

That said, some suppliers continue to provide lower voltage specifications for capacitors that today support voltages of 50V, for example.

In either of these two cases, it is ultimately not a problem to exceed voltage requirements, for example by using a capacitor specified for 25V or 50V with a requirement of 16V.

Alongside the base parameters considered here, there are a number of other aspects that play a role when selecting components, for example the required quality level or properties, depending on the application and field of use. Such properties may include Automotive Grade (usually AEC-Q200-qualified) or soft termination (also known as flexiterm, flexcrack resistant, resin external electrode, polymer termination among other similar expressions), which prevents the formation of cracks that notably can occur when bending PCBs (Figure 4).

Motivation for miniaturization

Miniaturization has other implications arising from the motivation behind them. While it may have been driven until recently by the demand for modern electronics to provide more and more performance, which increasingly limited the amount of space on the PCB, the primary factors today are more likely to be availability and cost-effectiveness (Figure 5), especially among suppliers. For developers, this means that they increasingly have to adapt to the pace of the suppliers and leave enough leeway for alternatives if they want to stay flexible and cost-effective-double-sourcing being key to this. This is especially true in the midst of challenging market conditions, which can always arise, even if just temporarily.

Further references to MLCC BIAS Ageing issues