Researchers at the Institute for Future Materials and Systems at Nagoya University in Japan have successfully synthesized barium titanate (BaTiO3) nanosheets with a thickness of 1.8 nanometers, the thinnest thickness ever created for a free-standing film.

Given that thickness is related to functionality, their findings open the door to smaller, more efficient devices. The research was published in the journal Advanced Electronic Materials.

Barium titanate (BaTiO3) ferroelectric material is commonly used as a dielectric insulation layer of class 2 MLCC multilayer ceramic capacitors.

The development of ever-thinner materials with new electronic functions is a highly competitive area of research. Such devices are especially important in ferroelectrics, materials that have a polarization that can be reversed by an electric field. This ability to reverse polarization makes these materials useful in memory and vibrational power generation.

However, as the materials used in these devices become smaller, they exhibit unexpected properties that complicate their industrial use. A big problem is the “size effect”, as when the material’s thickness is reduced to a few nanometers, its ferroelectric properties disappear.

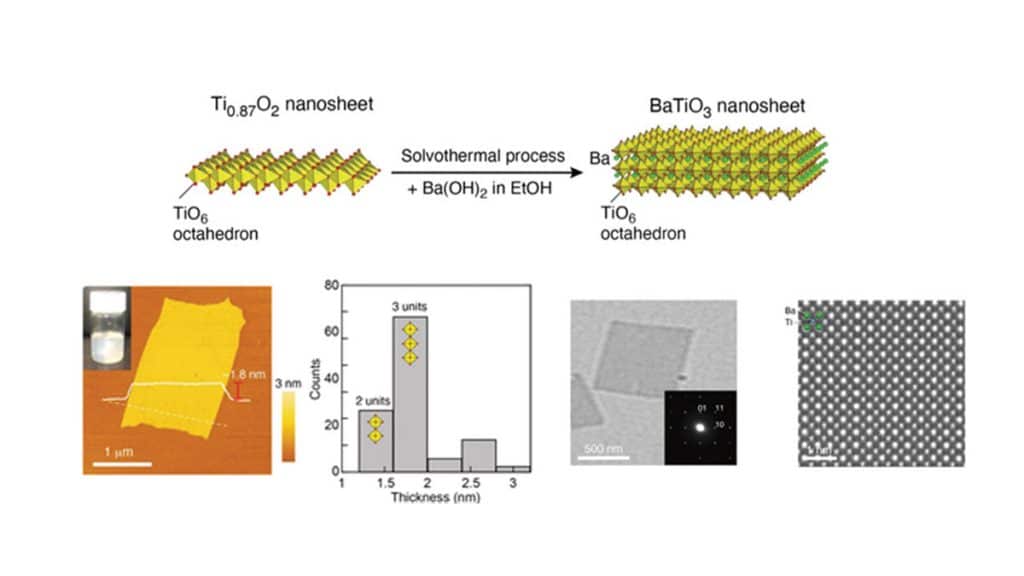

Now, a team from Nagoya University’s Department of Materials Chemistry and the Institute of Materials and Systems for Sustainability (IMASS), led by Professor Minoru Osada (he/him), has successfully synthesized defect-free BaTiO3 nanosheets with ferroelectric properties at a thickness of 1.8 nm using an aqueous solution process. The result is the thinnest free-standing film ever made. Although thin, the film exhibits ferroelectric properties, representing an important breakthrough in the fabrication of thin, ferroelectrically active films.

“However, for BaTiO3, a typical ferroelectric material, it is difficult to synthesize nanosheets by the conventional synthetic method. Therefore, it was necessary to develop a new synthetic method,” Osada said. “Generally, the synthesis of BaTiO3 requires a calcination process that requires temperatures of 1000°C or higher. In contrast, we synthesized BaTiO3 nanosheets at a low temperature of 60°C using our process. Since the thickness of the film can be controlled using this method by varying the reaction time, the synthesis of nanosheets with two to six lattices was achieved.”

“If nanosheets with a thickness of a few nanometers can be synthesized in ferroelectrics, new properties and applications are expected to be discovered. Our findings should provide an important technique for the miniaturization of devices such as memories and capacitors,” he continued. “As existing technologies have already reached their limits both in terms of both materials and processes, techniques such as ours are essential. They offer a dramatic increase in performance and technological innovation by the means of new materials and processes.”

Reference:

JOURNAL: Advanced Electronic Materials; DOI: 10.1002/aelm.202201239