Samsung Electro-Mechanics is investing significantly in MLCC ceramic capacitor technology for AI servers and automotive electronics.

This strategic move aims to reshape its business model by focusing on high-growth sectors such as AI servers and automotive electronics. Samsung is particularly drawn to MLCC’s ability to provide best-in-class ultra-small, high-capacity technologies.

Focusing on AI Servers and Automotive Electronics with Best-in-Class Ultra-Small, High-Capacity Technologies

Its core business, MLCC (Multi-Layer Ceramic Capacitor), is expanding from its traditional role in IT sectors like smartphones into future-driven industries such as AI servers, xEVs (electric vehicles), advanced driver assistance systems (ADAS), and autonomous driving. Samsung Electro-Mechanics is focusing its capabilities on these areas with an emphasis on advanced, high-margin technologies.

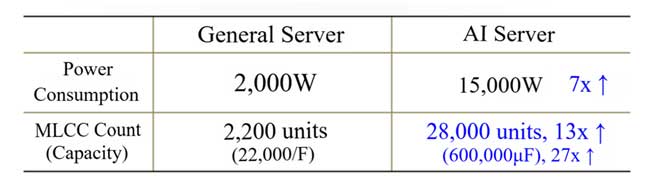

Driven by the spread of AI, rising EV adoption, and the evolution of autonomous systems, the demand for MLCCs in AI servers and automotive electronics is expected to grow significantly. A single electric vehicle requires approximately 20,000 to 30,000 MLCCs, and state-of-the-art AI servers use more than ten times the MLCCs found in general-purpose servers.

AI servers require high-performance, densely integrated MLCCs—specifically, compact, high-capacity components that can withstand high temperatures (105°C). In contrast, automotive MLCCs, which are critical to human safety, demand high-capacitance, high-temperature (125–150°C), and high-voltage (<2000V) components with exceptional reliability.

In response, Samsung Electro-Mechanics is leading the market with high-performance MLCCs capable of enduring high temperatures (150°C), high voltages (2000V), shock, and humidity.

The company is also eyeing the humanoid robot sector, emerging as a next-generation electronics platform, and plans to leverage its high-reliability industrial and automotive technologies along with ultra-high-capacity IT solutions to gain early market dominance.

Advanced Technology in a Component Thinner Than a Hair

An MLCC (Multi-Layer Ceramic Capacitor) stores electrical energy and supplies it stably to active components like APs, CPUs, and GPUs, ensuring smooth operation. It also filters noise between signals, thereby improving device performance and stability.

MLCCs are essential to modern electronics—over 1,000 are used in a single smartphone, and tens of thousands are installed in electric vehicles.

Sizes range from 0.2mm x 0.1mm—thinner than a human hair (about 0.3mm)—to 5.7mm x 5.0mm, making many MLCCs barely visible to the naked eye.

Despite their minuscule size, MLCCs house 500 to 1,000 stacked layers of dielectric and electrode materials. Their density and complexity make them extremely high-value components—just 300ml, roughly the volume of a wine glass, can be worth hundreds of millions of Korean won.

MLCCs Demand the Highest Degree of Micro-Level Precision

The strength of MLCCs lies in storing large amounts of electricity in a small form factor. This is achieved by alternating layers of dielectric and electrode materials, requiring advanced material and manufacturing technology to stack layers evenly and interference-free.

If semiconductors present the highest barrier to entry at the nano scale, MLCCs do so at the micro scale, making the manufacturing process equally demanding.

MLCCs are produced by printing and stacking ultra-thin layers of ceramic and nickel, then firing them at high temperatures like ceramic pottery. The performance of each product depends heavily on what additives are mixed into the ceramic base and in what quantities—a critical proprietary technology for manufacturers.

The thinner and denser these internal layers, the greater the storage capacity—thus, extremely precise control over the manufacturing process is vital. These components must be fired at over 1,000°C, with carefully calibrated temperatures to compensate for differences in thermal expansion between ceramics and metal.

Any microcracks formed during firing can render an MLCC defective. Therefore, even if a product appears undamaged, it must undergo rigorous quality checks, including electrical property testing and visual inspection.

Samsung Electro-Mechanics began its MLCC business in 1988, launched industrial and automotive production in 2016, and established a dedicated automotive production line in Busan in 2018 to accelerate its efforts.

To strengthen competitiveness, the company also develops and manufactures its own core ceramic materials, a rare capability mastered by only a handful of companies globally. A dedicated raw materials plant for automotive applications was completed at the Busan site and began operations in 2020.

Currently, Samsung Electro-Mechanics conducts R&D and new product development in Suwon and Busan, and mass-produces MLCCs at its facilities in Tianjin, China, and the Philippines.

AI Server MLCCs: The Next High-Growth Market

AI server MLCCs are emerging as the next major market after automotive. Notably, the AI server sector is expected to grow faster than the general server market.

According to MarketsandMarkets, the global AI server market is projected to grow from $142.9 billion (about 196 trillion KRW) in 2024 to $837.8 billion (about 1,150 trillion KRW) in 2030.

MLCCs for servers require superior durability and resistance to temperature and humidity compared to those used in general IT environments. AI servers, in particular, demand greater computational power and massive data throughput, leading to higher power consumption and heat generation.

Thus, MLCCs for AI servers must operate reliably in extreme conditions, including high temperatures (105°C or above), high rated voltages (100V), and high bending strength (2mm).

As AI servers consume five to ten times more power than standard servers, they require more MLCCs. However, space for mounting MLCCs near GPUs is limited, necessitating compact, ultra-high-capacity designs. AI servers are typically designed with stacked boards containing multiple GPU modules, resulting in increased heat generation. Therefore, MLCCs that can operate in high-heat (105°C) environments are essential.

Samsung Electro-Mechanics is expanding its product lineup with ultra-small, ultra-high-capacity, high-temperature, and high-voltage MLCCs. It currently holds approximately 40% of the global AI server MLCC market, cementing its position as a global leader.

Automotive MLCCs Require Extreme Reliability and Durability

Automotive MLCCs, similar to those used in IT products, operate in demanding conditions and are directly linked to human safety, necessitating exceptional durability and reliability.

These components must function consistently under extreme temperatures ranging from above 125°C to below -55°C, endure mechanical stress, and withstand humidity levels as high as 85%.

The development cycles for automotive MLCCs are approximately three times longer, and their prices are over three times higher compared to those of IT counterparts, underscoring their high value-added nature. With the emergence of ADAS (Advanced Driver Assistance Systems) as the backbone of autonomous vehicles, the demand for high-performance MLCCs continues to rise, as these systems require precise electronic control.

To meet the stringent automotive standards, materials must be engineered to withstand high temperatures and voltages, while microstructures must be optimized for shock and humidity resistance.

Furthermore, these MLCCs must adhere to AEC-Q200 certification, a stringent automotive quality standard, and undergo rigorous validation from each customer before entering production.

According to McKinsey, the adoption rate of ADAS Level 2 and above is projected to increase from 44% in 2025 to 65% by 2030, accompanied by a market value surge from $38.5 billion to $65 billion.

Samsung Electro-Mechanics has consistently advanced its automotive MLCC technology roadmap.

In 2021, the company developed two MLCCs specifically tailored for ADAS applications. The following year, it released 13 MLCC models for automotive powertrains. In 2024, the company introduced two 16V MLCCs for ADAS featuring the world’s highest capacitance, along with 2,000V-rated MLCCs for EVs.

Looking ahead, Samsung Electro-Mechanics plans to introduce the world’s first LiDAR-specific MLCCs in 2025, further solidifying its position as a technology leader in the automotive electronics market.