This blog article written by Jaroslav Slavomir, KYOCERA-AVX Corporation discusses tantalum polymer solid electrolytic capacitors and its use in automotive applications.

Introduction

Tantalum electrolytic capacitors are constructed using a sintered pellet of powdered tantalum as the anode of the device.

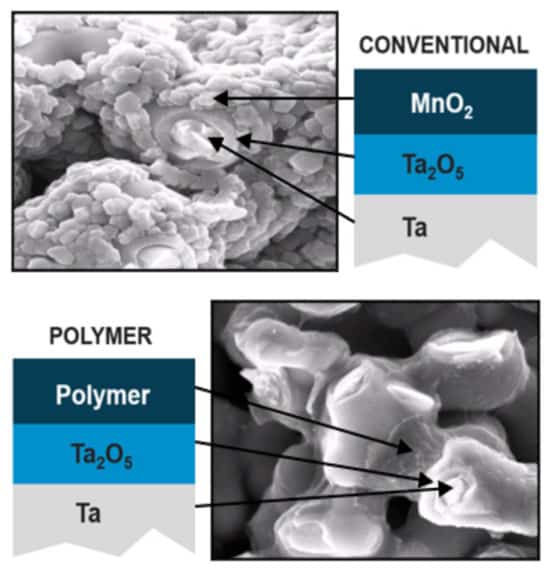

A grown oxide layer on the contoured surface of the pellet acts as the dielectric insulator, and a cathode terminal is formed using either a conventional MnO2 electrolyte or a conductive polymer to sufficiently contact the oxide layer.

These two varieties of cathode construction are shown in Figure 1.

The final capacitor can be packaged in many forms, and the typical J-lead surface mount construction is shown in Figure 2. The capacitive structure is bonded to a molded case and electrically interfaced using carbon as a separation layer and silver for connection with the lead frame.

Tantalum capacitors are widely known for their superior performance, especially in high reliability, harsh environment applications. Using a solid polymer electrolyte extends this performance by reducing electrical series resistance (ESR) and enabling higher voltage operation.

This article discusses, in particular, the advantages that automotive solid polymer electrolytic capacitors bring; standard ranges are not tested per AEC-Q200 requirements and are therefore not dedicated to the harsh conditions of automotive applications.

Tantalum Polymer Capacitors Benefits

In general, tantalum capacitors offer significant benefits compared to other capacitor families. One example is the stability of tantalum bulk capacitance across applied DC voltage. In contrast with Hi-Cv MLCC class II dielectric capacitors, for instance, where rapid capacitance drop with DC BIAS applied voltage could be more than 50% at half of the rated voltage, tantalum devices maintain their capacitance across the entire rated voltage range.

In practice, a bank of MLCCs can be replaced with a smaller number of polymer capacitors. This solution occupies less PCB space and provides various other performance benefits. When considering polymer solid tantalums specifically, ESR is often a primary concern. A conventional tantalum capacitor based on MnO2 electrolyte has a relatively high ESR due to the low conductivity of this material.

On the other hand, conductive polymer capacitors have greatly improved conductivity, leading to a significant reduction in ESR through the entire operating frequency range. Figure 3. shows a comparison of polymer and traditional tantalum capacitors.

In addition to ESR reduction, the polymer capacitor exhibits a unique self-healing mechanism. Figure 4 shows that dielectric failures result in a higher current path and associated self-heating. This, in turn, evaporates/carbonizes the polymer material and encapsulates the failure location with a non-conductive polymer layer. The polymer material does not contain any oxygen, unlike MnO2 technology, and is non-flammable. As a result, polymer capacitors are more reliable, safer, and less sensitive to inrush current and higher ripple

current limits.

KYOCERA AVX tantalum polymer capacitors are qualification tested to 2,000 hours to exceed the 1,000 hour automotive standards. But to further validate the reliability of these polymer solid electrolytic capacitors, KYOCERA AVX did additional testing to 3,000 hours at 125°C. Figure 5 (left) demonstrates that even after 3,000 hours, the ESR shift is still well below the 100% threshold.

Similarly, the change in capacitance, shown at right in Figure 5, remained less than -2.0% out to 3,000 hours. This is 10x better than the -20% limit for lifetime capacitance change. This data validates the long-term stability of polymer capacitors in harsh environments, a necessary characteristic for automotive applications in particular.

Tantalum Polymer Capacitors for Automotive Applications

The inherent performance benefits of tantalum polymer solid capacitors make them an ideal candidate for harsh environment automotive applications. These capacitors offer a host of unique properties, including:

- Meets and exceeds requirements of AEC-Q200

- Conductive polymer electrode for lower ESR

- Humidity 85°C/85%RH, Vr, >1,000 hours

- -55 to +125°C/150°C operation temperature

- DCL leakage current: 0.1CV (at UR )

- Full voltage range: 2.5-50 V

- 3x reflow 260°C compatible

KYOCERA AVX’s qualification of tantalum polymer solid capacitors meets and exceeds the requirements of AEC-Q200. Extended temperature capability offering stable performance up to 2,000 hours at 125°C meets the lifetime requirement of approximately 15 years for vehicle applications at 85°C. The following two tables present available capacitors for automotive designs at normal and extended temperature ranges.

Automotive power supply systems typically involve a network of series and parallel connected DC/DC converters to deliver numerous voltages from the main battery bus. A representative example would consist of a 12 V battery as the primary source being converted to 5.0 V, 3.3 V, and 1.8 V for electronic subsystems such as infotainment, cabin comfort control, and peripheral vehicle sensors.

These DC/DC converters require filtering on both the input and output sides to absorb changes in load current and cope with electromagnetic interference (EMI) from surrounding systems.

While MLCC’s are often the designer’s first choice for low ESR, low-cost capacitors, they present challenges in the automotive environment due to DC bias capacitance reduction and a limited choice of capacitance/voltage combinations. As shown in Figure 8., polymer solid electrolytic capacitors can be used to complement MLCC filtering circuits by providing large bulk capacitance in a much smaller overall footprint.

The rapidly growing electric vehicle (EV) market uses at least ten times more electronic components than traditional combustion engine vehicles. The electronics industry struggles with the associated demand for capacitors, and MLCC Hi-CV capacitor shortages have become commonplace.

AEC-Q200 polymer capacitors are an ideal alternative and provide a long-term solution to this supply chain crisis. More importantly, polymer capacitors come with the added benefit of higher performance. They offer higher active capacitance than MLCC technology without voltage and temperature dependency. Compared to tantalum MnO2 equivalents, polymer capacitors exhibit lower ESR and a benign failure mode.