TDK Corporation has extended the automotive-grade CA series of its MEGACAP MLCCs modules with a metal frame. Mass production of the product series began in September 2024.

In recent years, the development of automobiles with electric powertrains, such as hybrid- (HEVs) and battery-electric vehicles (BEVs), and highly efficient charging technologies, has significantly progressed. Both help to reduce greenhouse gas emissions.

In these applications, the power consumption of various subsystems including inverters, onboard chargers (OBCs), and wireless power transfer (WPT) systems is increasing, and MLCCs ceramic capacitors must handle high ripple currents and have large capacitance.

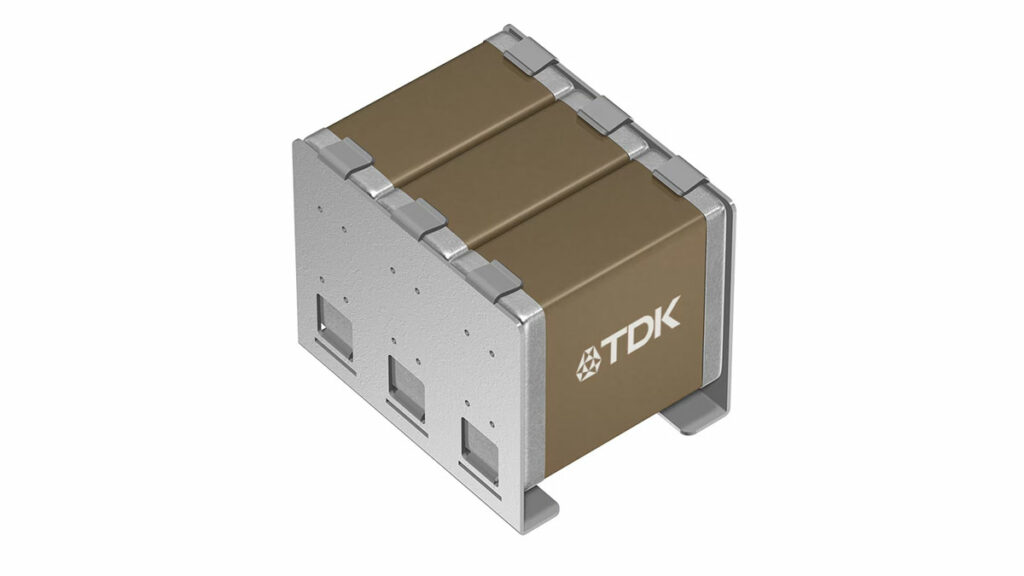

To meet these needs, TDK developed the CA series, the largest MLCCs modules in the industry (6.00 x 5.60 x 6.40 mm) with a metal frame and 3-line type structure. TDK now provides an extensive lineup including 99 nF/1000 V with a Class 1 dielectric and 47 μF/100 V with a Class 2 dielectric.

To handle high currents, TDK has reduced the equivalent series resistance (ESR) compared to the previous products by optimizing the materials of the metal frame. This helps reduce the number of components and miniaturizes devices. TDK will further expand its lineup to meet the needs of customers.

Features

- Low resistance achieved by optimizing metal frame materials

- High capacitance achieved using multiple MLCCs to help reduce the number of components and miniaturizing devices

- High reliability qualified based on AEC-Q200

Applications

- Smoothing and decoupling of the power lines

- Resonant circuits in subsystems such as OBCs and WPTs

- Snubber circuits in inverters