Vishay announced completion of its 10 part video series of thermistor simulation for the temperature control of thermoelectric modules, heat detector temperature compensation of resistive strain gage sensors, air flow detection, and more general PID temperature control circuits.

Thermistor applications make sense in many applications: NTC or PTC thermistors are needed for temperature sensing and compensation, protection against overvoltages, and the attenuation of surge currents.

The electronic simulation of analog electronics using models of these thermistors can help design engineers working in these fields to develop their intuition.

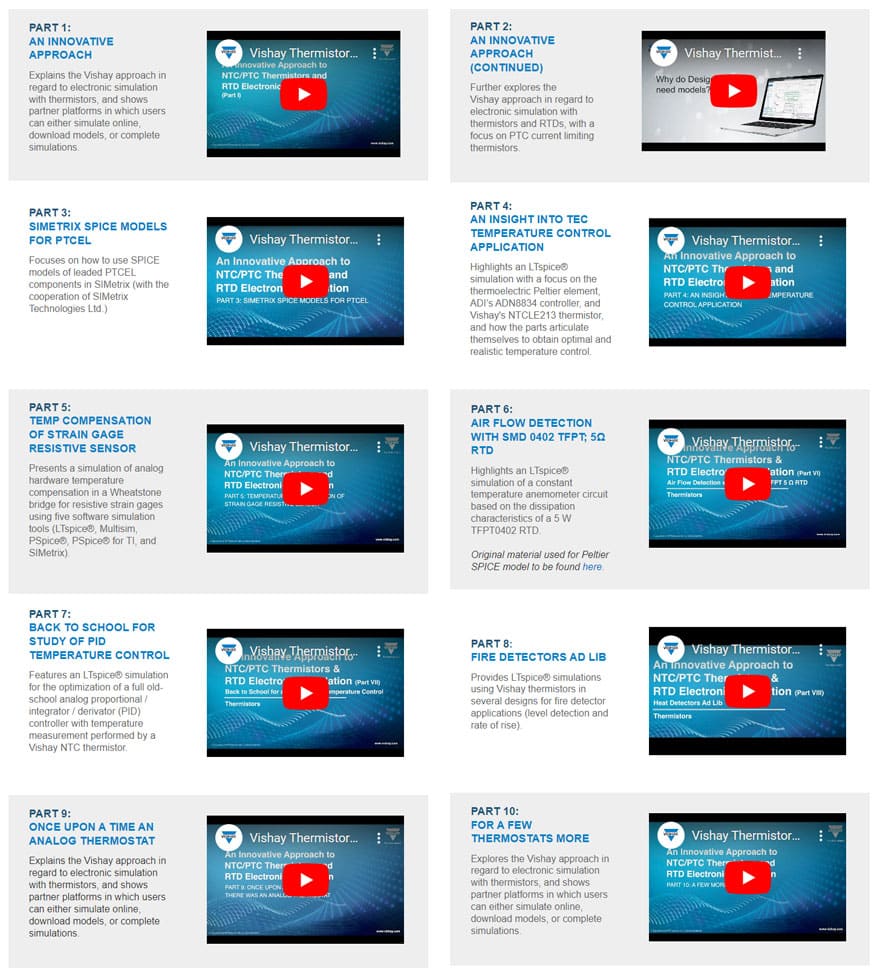

This video series — dedicated to electronic simulation with Vishay thermistors and RTDs — will explore design simulations for the temperature control of thermoelectric modules, heat detector temperature compensation of resistive strain gage sensors, air flow detection, and more general PID temperature control circuits.

BENEFITS

By integrating the Vishay models directly into their corporate or personal software, design engineers will be able to simulate their circuits, exploring worst case scenarios or Monte Carlo distributions for the component tolerances.

They will acquire a better understanding of their applications by pushing their tolerance limits. This will eventually lead to cost savings, as it can eliminate tedious hours of trial and error in the lab.

Whether they use LTspice®, PSpice® (for TI), SIMetrix, TINA TI, Multisim, Altium Designer, or another multi-domain language like VHDL AMS (Siemens EDA), Vishay’s models will work in a plug and play mode.

Thermistor Simulation Videos

to view Vishay thermistor simulation videos click on the link here or the image below.