This article written by Benjamin Blume, Team Leader Application Engineering Europe at Samsung Electro-Mechanics Co., describes the company’s proprietary copper-based MLCC soft termination that outperforms conventional silver-based soft terminations in harsh automotive dew tests.

The automotive industry is notorious for its rigorous testing standards. Only the highest quality electronic components are able to meet the requirements of these demanding tests, which often take place in extremely harsh environmental conditions.

The automotive dew test is a case point, an examination of integrity that calls out electronic systems featuring MLCCs multi-layer ceramic capacitors with silver-epoxy soft terminations. To ensure MLCCs pass the highly demanding dew test, it is necessary for design engineers to adopt a more astute MLCC strategy.

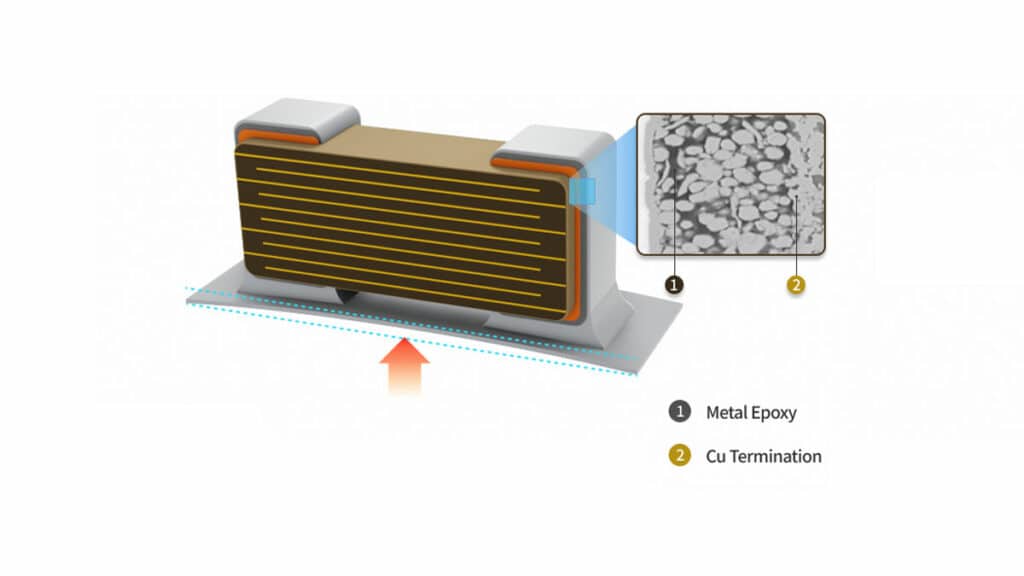

Samsung Electro-Mechanics Co (SEMCO) has the optimal solution – and it involves a proprietary, field-proven copper-based soft termination variant with high bending strength that outperforms conventional silver-based soft terminations. This advance eliminates silver migration issues and improves MLCCs robustness in automotive dew tests.

Soft terminations improve the mechanical robustness of brittle Class II MLCCs used extensively in automotive electronics. Brittleness is an inherent characteristic of ceramic dielectric materials, making automotive-grade MLCCs more prone to mechanical stress than most other surface-mounted PCB components.

By allowing a certain amount of ‘bending strength’ in the event of circuit board flex, soft terminations prevent unwanted outcomes such as cracking and/or short circuits. The conventional material of choice for soft terminations is silver-epoxy. However, there is a problem when it comes to certain automotive tests. Specifically, OEMs require suppliers of electronic systems to pass a dew test. The high humidity of this test can lead to migration between the terminals of MLCCs. Even though other metals can migrate, silver is the most problematic because it migrates fastest.

Power Applications Humidity Concerns

High-humidity environments present a particular hazard for a multitude of electronics applications that include various powertrain components. The main inverter, for example, makes direct use of high-voltage battery power through a MLCC DC-Link capacitor.

Further powertrain systems that can fall foul of dew tests without the right MLCCs in place include on-board chargers, battery management systems, DC-DC converters, transmission control units (TCUs) and electronic control units (ECUs). Indeed, the issue can apply to all ECUs that are not coated, which is the majority.

Humidity is of biggest concern for MLCCs that see a low AC load (and thus stay cold), but have a constant DC load. In high-voltage circuits, the issue can become increasingly important as higher voltages raise migration force.

The powertrain is just the tip of the iceberg when it comes to systems that are vulnerable to condensation. Chassis and body electronics such as the airbag control unit (ACU), electric power steering (EPS) and HVAC (heating, ventilation and air conditioning) all warrant scrutiny when specifying MLCCs.

Further examples are evident in ADAS (advanced driver assistance system) applications like smart cruise control (SCC), light detection and ranging, the night vision system and the autonomous control unit.

Proprietary Copper-Based Soft Termination Benefits

The successful operation of these advanced systems relies on a mix of general, mid/high-voltage, high-temperature and ESD protection MLCCs offering soft terminations.

To explain why, consider the Volkswagen VW80000 standard, which sets out the general requirements, test conditions, and test procedures for electric and electronic components in motor vehicles. The K-15 test specified in the VW80000 standard simulates condensation on electronic modules to evaluate their robustness.

Volkswagen’s K-15 test defines a relative air humidity of 100% during the condensation phase, while the duration of the test is 32.5 hours (five cycles of 6.5 hours each). This demanding environment results in water drops that condense on components, especially those experiencing no load. A good example is an MLCC stabilising a voltage with low ripple current, which is one of the most frequent use cases of MLCCs.

High humidity and water drops accelerate migration between terminals with different potential. The answer, clearly, is to eradicate as much as possible the silver content of the termination to avoid rapid migration. Although other metals can (and do) migrate, the rate of migration is sufficiently slow to meet the requirements of dew tests set out by the automotive industry.

SEMCO moved from silver-epoxy to copper-epoxy for its soft terminations more than 10 years ago and continues to increase its line-up into high capacitance, high voltage, downsizing and bigger case sizes, and provides it in new automotive MLCCs released.

All of the company’s automotive Class II MLCCs are today available with metal-epoxy preventing silver migration. In fact, SEMCO is the only supplier providing copper-epoxy in its high bending strength automotive line-up to avoid silver migration. As a point of note, the use of copper-based soft terminations has no detrimental effect on the overall humidity life performance/robustness of the MLCCs that comply with all AEC-Q200 automotive test requirements.

Since 2023, all new SEMCO MLCCs for the automotive industry feature copper-epoxy technology. Some other suppliers offer special MLCCs featuring a coating to protect against migration, but at a higher cost.

MLCC Robustness Improvements

As well as putting an end to silver migration issues and making it simple to pass otherwise challenging automotive dew tests, capacitors with soft or failsafe/soft terminations offer outstanding bending strength to help prevent crack mitigation in vulnerable areas, such as on the 12V battery line near the hole and connector.

One of the most prevalent reasons behind MLCC failures is cracking. Among the principal drivers of this unwanted effect are separating the PCB into single modules by breaking (bending), screwing the PCB into the housing and having the MLCC too close to the screw.

Depending upon the severity, cracks may not cause MLCC failure during final assembly tests, which is a major problem for manufacturers of on-vehicle electronic systems. Over time, moisture penetration into the crack can cause a reduction in insulation resistance and eventual dielectric breakdown. The upshot is capacitor failure in service, leading to potential warranty costs and loss of reputation.

Another failure mode promoted by cracking is a potential short circuit. This outcome can not only destroy the MLCC, but also damage surrounding components, the PCB and adjacent circuit board assemblies.

Summary

Adopting MLCC solutions with SEMCO’s unique soft termination variant means that automotive electronic system manufacturers benefit from both far lower metal migration and termination robustness, essentially removing a contradicting design ambition.

SEMCO’s copper-epoxy soft termination variant in its high bending strength automotive MLCC line-up does not have silver migration during automotive dew tests. Furthermore, SEMCO MLCCs offer high bending strength of up to 5mm according to AEC-Q200, the global standard for stress resistance that all passive electronic components must meet. In other words, SEMCO guarantees no bending cracks for board flex of up to 5mm.

By solving this long-standing issue in a cost-effective, added-value way, SEMCO stands at the vanguard of MLCC technology development for automotive customers. Over a decade of success in this area proves the high reliability of the company’s silver-migration-free soft terminations.

Samsung Electro-Mechanics Co. Contact Inquiry