This article based on TDK blog article discus a technical perspective of EMI electromagnetic noise mitigation in automotive 48v power supply systems.

This article integrates deeper insight from multiple sources, including TDK’s measurements and broader industry perspectives from Texas Instruments and Monolithic Power Systems.

The shift toward 48V electrical architectures in modern vehicles—driven by the demands of electrification, ADAS, and autonomous systems—has introduced new challenges in electromagnetic compatibility (EMC). This paper explores the underlying causes of increased EMI in 48V systems, evaluates filter design strategies, and presents empirical data from conducted noise measurements. It synthesizes insights from component-level behavior, system integration constraints, and regulatory compliance, drawing on both manufacturer data and independent engineering analyses.

1. Introduction

The automotive industry is undergoing a profound transformation, with electrification and digitalization pushing the boundaries of traditional power distribution systems. The 12V architecture, long a staple of vehicular electronics, is increasingly inadequate for supporting high-performance processors, electric turbochargers, and integrated starter generators (ISGs). In response, manufacturers are adopting 48V systems, which offer reduced current for equivalent power delivery, enabling lighter wiring harnesses and improved thermal efficiency.

However, this transition is not without consequence. The increased voltage inherently amplifies switching transients and parasitic coupling, leading to elevated levels of conducted and radiated noise. These effects are particularly pronounced in systems with high-frequency DC/DC converters and dense PCB layouts. As such, EMC design has become a critical bottleneck in 48V system deployment.

2. Noise Generation Mechanisms in 48V Systems

The root of the EMI problem lies in the physics of switching power conversion. When a DC/DC converter operates at higher input voltages, the energy stored and released during each switching cycle increases proportionally. This results in sharper voltage and current transitions, which in turn excite parasitic elements—such as stray inductance and capacitance—across the board.

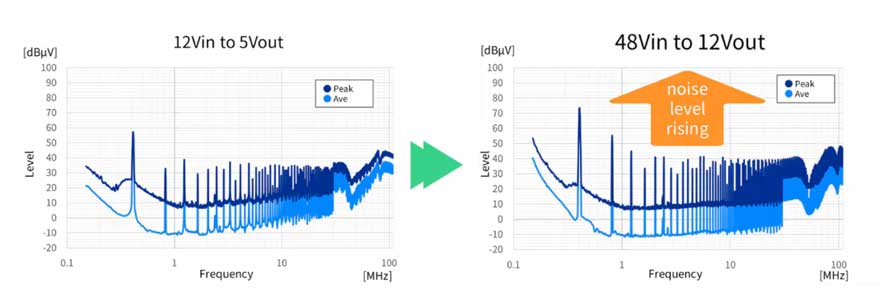

TDK’s comparative measurements between 12V and 48V systems using identical board layouts reveal a marked increase in conducted noise across the 150 kHz to 108 MHz spectrum. The higher voltage not only increases the amplitude of switching noise but also broadens its frequency content, making suppression more complex. These findings align with broader industry observations, such as those from Texas Instruments, which note that 48V systems must meet stringent CISPR 25 Class 5 requirements for EMI compliance.

3. Filter Design Strategies

To address these challenges, engineers typically employ multi-stage filtering architectures. The most effective configurations combine common-mode chokes (CMCs), π-type low-pass filters, and multilayer ceramic capacitors (MLCCs) with tailored impedance profiles.

The common-mode choke plays a pivotal role in suppressing noise that couples through parasitic capacitance between power and ground planes. Its differential winding structure allows it to attenuate both common-mode and differential-mode currents, especially in the 1–30 MHz range where automotive EMI is most problematic.

The π-type filter, composed of series inductors and shunt capacitors, targets normal-mode noise generated by switching regulators. Its effectiveness depends heavily on the selection of capacitors with low ESR and stable capacitance over temperature. MLCCs with X7R dielectric and high voltage ratings (e.g., 100V) are preferred, as they maintain performance under thermal and mechanical stress.

TDK’s implementation, for instance, uses CGA6P1X7R2A106K250AC (10 µF, 100V) and CGA5L1X7R2A475K160AC (4.7 µF, 100V) MLCCs in combination with ACM12V-172-2PL-TL00 CMCs and SPM7054VC-1R5M-D inductors. This configuration achieves substantial noise attenuation while minimizing component count and PCB footprint.

4. Measurement and Validation

Empirical validation is essential in EMC design. TDK conducted measurements in a 3-meter anechoic chamber using a 48V-to-12V DC/DC converter operating at 400 kHz and 7.2A output. The conducted noise was measured using the voltage method across the 150 kHz–108 MHz band.

Without filtering, the system exhibited significant peaks in both low and mid-frequency ranges. Upon integrating the multi-stage filter, noise levels dropped markedly, confirming the effectiveness of the chosen topology. Notably, the use of large-capacitance MLCCs allowed for a reduction in the number of components—from five 4.7 µF units to three 10 µF units—without compromising performance.

These results are consistent with findings from Monolithic Power Systems, which emphasize that 48V buck converters must be carefully designed to meet EMC regulations while maintaining thermal and electrical efficiency.

5. System-Level Considerations

Beyond component selection, system-level integration poses additional challenges. The increased voltage necessitates careful attention to creepage and clearance distances, especially in environments subject to high humidity or contamination. ISO 21780 specifies transient voltage requirements up to 70V, which must be factored into regulator design and layout.

Moreover, the dual-voltage nature of mild hybrid electric vehicles (mHEVs)—which combine 12V and 48V subsystems—introduces complexity in grounding schemes and isolation. Designers must ensure that noise from the 48V domain does not propagate into sensitive 12V circuits, particularly those associated with infotainment and safety-critical functions.

6. Conclusion

The adoption of 48V power supply systems in automotive applications offers compelling benefits in terms of efficiency, weight reduction, and support for high-performance electronics. However, it also introduces significant EMC challenges that must be addressed through rigorous filter design and validation.

Multi-stage filters incorporating CMCs, π-type topologies, and high-voltage MLCCs have proven effective in suppressing both common-mode and normal-mode noise. Empirical data supports their use, and industry standards provide a framework for compliance. As automotive systems continue to evolve, the integration of robust noise mitigation strategies will remain a cornerstone of reliable and safe vehicle design.