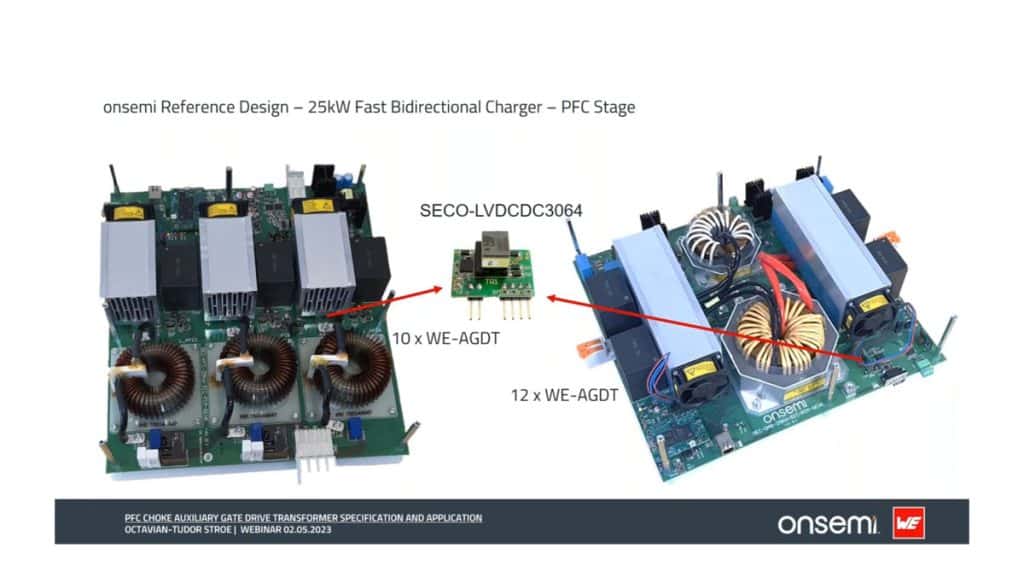

In this webinar three speakers from OnSemi and Würth Elektronik introduce design architecture of SiC based 25kW EV charger and selection of chokes & capacitors to fit it needs.

In this webinar we will show you

- Basic block diagram for building a 25 kW DC fast charger

- How a PFC choke works

- PFC choke parameters

- Advantage of flat wire choke design

- Benefits of using a WE-AGDT auxiliary gate drive transformer

- Circuit implementation of such a gate drive transformer

- Characteristics of the DC link capacitors

- Advantages of WCAP-FTDB polypropylene film DC link capacitors

Speaker 1 – Didier Balocco, onsemi

Both the basic block diagram for building a 25 kW DC fast charger and the architecture for building a complete system will be explained. In addition, the specifications will be explained in detail and some results will be presented. The main OnSemi components used to build the fast charger will also be presented.

Speaker 2 – Octavian Stroe, Würth Elektronik

Power chokes with flat wire design are passive elements specially designed for use in active PFC circuits. In combination with active boost PFC circuits, these chokes achieve high efficiency and a power factor between 0.90 and 0.99. The WE-AGDT series from Würth Elektronik makes it easier than ever to implement discrete SiC gate driver designs. These off-the-shelf components are compact SMT transformers optimized for silicon carbide applications. With extremely low interwinding capacitance, the WE-AGDT helps achieve higher common mode choke transient immunity (CMTI).

Speaker 3 – Jon Izkue Rodriguez, Würth Elektronik

DC link capacitors are placed between a DC source (battery or rectified DC) and a power stage such as an inverter or motor drive to provide a temporary buffer of energy. Würth Elektronik eiSos introduces the new DC-Link film capacitors to provide solutions for the high energy density applications of the future in e-mobility and renewable technologies. The WCAP-FTDB capacitors offer high ruggedness and stability over a long load life thanks to the metallized polypropylene film (MKP).