Researchers from Wrocław University of Science and Technology, Poland presented their scientific paper on printing and ageing of flexible capacitors by Ink-Jet prints.

Abstract

Correct operation of electronic circuits (including those made with the ink-jet printing technique) requires the electrical parameters of the structures to be constant or to be changeable, but in a predictable way.

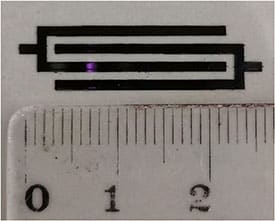

Due to that, the flexible, ink-jet printed interdigital capacitors (IDSs) were made and then tested in various conditions. We used the conductive silver-based Amepox AX JP-60n ink. As a substrate, we chose the transparent, flexible Melinex OD foil with a thickness of 125 µm.

The IDCs were designed and their capacitances were simulated using Comsol Multiphysics Software. Then the test structures were fabricated by the ink-jet printing process using Dimatix DMP 2831 printer. The printed structures were subjected to environmental exposures in a climate chamber to check the influence of temperature and humidity on the tested samples. The IDCs were also subjected to cyclic bending and straightening tests to analyze the outflow of tensile forces on the printed structures, which are exposed to the common factors, that could diminish the quality of the printed and flexible devices.

Due to the small capacitance values of the designed and made IDSs, the measurements showed the key importance of the measuring table on which flexible substrates with IDC capacitors were placed for their capacitance value. Performed tests also demonstrated that in most cases, the capacitors are characterized by an increase in capacitance by a few to a dozen or so % after the ageing tests. Obtained results could be a good groundwork for further research, that will include ways of preventing the creation of discontinuities—or minimizing their impact on the printed device performance.

Introduction

Capacitors are the most commonly used passive components. Their applications are not limited to only electronic devices. However, the development of areas strictly associated with electronics are in constant relationship in the evolution of these components. For instance, capacitors are used in applications such as decoupling or interference filters, signal circuits, and many more. Other, slightly more sophisticated applications are sensors and actuators.

Simultaneously with constant development of microelectronics technology, the possibility of manufacturing of such components also is increased. Among them, many techniques can be mentioned for fabricating the microelectronic planar components. Such techniques can be divided into two main fields, the subtractive (e.g. photolithography) and additive (e.g. screen- or ink-jet printing) ones. Ink-jet printing has been a well-known method of depositing inks on a generally planar substrate for several dozen years.

The issue of printed electronics has been ongoing for several decades. However, the printing leaves a wide margin for adaptation of the printed components, which can be identified as its main advantage. Ink-jet printing is a technique that has been evolving in microelectronics steadily for more than half a century. It allows the choice of many materials as a substrate for circuits, including flexible ones, addressing wearable electronics, which is a constantly growing area. Such materials that can act as a substrate for ink-jet printing electronic devices or circuits are i.e. paper, polyethylene terephthalate, polyimide foils, for example Kapton, polyethylene naphthalate (PEN), ceramics and many others.

All circuits that have been manufactured using ink-jet printing are the significant part of the area of ‘printed electronics’. Importantly, the use of this technique assumes the planarity of the circuit components. Due to this, it was decided to develop a method to fabricate interdigital capacitors (IDCs), which are mentioned in the literature. Such capacitors can be manufactured using various techniques near printing methods. In microelectronics, the most common are those that are made using the techniques characteristic of semiconductor technology. However, techniques that are dedicated to silicon or glass substrates with undoubted advantages (resolution, repeatability) are the most expensive ones.

The durability of the material from which the electronic components are made is one of the most essential aspects of printing structures. In the case of ink-jet printed layers, they are characterized by sensitivity to mechanical microdamage and the degradation of applied inks due to oxidation of the printed metallization, especially silver. Due to that, it was decided to characterize the developed structures by an ageing process in the climate chamber to verify that it took into account the functional properties—capacitance and dielectric loss factor.

Therefore, the paper presents the characteristics of the ink-jet printed IDC capacitors with various geometrical parameters with the verification of their resistance to harsh work conditions. The capacitors analyzed and presented in the article were made without dielectric ink. Of course, there are references in the literature to publications that include dielectric ink for high-energy storage or highly flexible electrochromic and energy storage devices.

Discussion

The literature shows that the capacitance of such capacitor results directly from the distance between the electrodes and the value of the permittivity of the dielectric that is between them. The investigations carried out show that each of these parameters significantly influences the capacitance value, as expected. When the measurement conditions (in air and on the ceramic table) it was possible to verify the impact of the permittivity on the capacitance value, which was also expected. Moreover, the capacitance of the IDCs tested directly on the table was higher, because of the difference in the effective permittivity of the medium, where the IDCs have been placed.

For most ceramic materials, the relative permittivity is about 7–10, while for air it is very close to 1. With the interdigital geometry of the capacitor electrodes, which provides the more scattered distribution of the electric field around the electrodes, it was expected phenomenon. The table had a significantly higher value of permittivity than that of air, which should have increased the measured capacitance. Indeed, the Melinex OD substrate allowed the capacitance to vary with the measurement conditions, which offers prospects for further sensing applications of printed structures. Furthermore, as expected, it is seen that increasing the number of fingers (which has an impact on the area between the electrodes) has a linear effect on the capacitance values. Moreover, changing the distance between the electrodes affected the capacitance proportionally. Thus, the authors conclude that using the proposed technology, it is possible to produce a capacitor with the desired parameters, and the choice of IDC geometry provides a suitable basis for likely applications as sensors. One of the possible ways to check in the further research is the use of capacity changes in the i.e. temperature or humidity determining.

Due to the fact that sensors frequently work in harsh environments, it was decided to carry out ageing tests. The results show that, for sensors with IDC configuration and ink-jet printed electrodes, the change in parameters is slight but noticeable and probably irreversible. The possibly reason for changing the capacitance could be the appearance of water in the printed structure due to repeatable changes of the ambient air temperature. Thus, this water probably indicates the presence of microdiscontinuities. This issue requires further research to prevent the aforementioned risk. Moreover, the printed metallization layer itself is sensitive to mechanical damage. Therefore, in the case where an IDC would be exposed to mechanical damage to the conductive layer, it would be recommended to cover the layer with a material that would provide protection. It would have a minimal influence on the permittivity and then cause slight changes in the capacitance (to the higher values).

Conclusion

Interdigital structures are an important part of many electronic devices. Many of them are fabricated using techniques which are characteristic of microelectronics. In this work, the IDSs were designed, fabricated, measured, and treated by various conditions in the ageing chamber. The geometry varied (0.5-, 1.0-, and 1.5 mm width of each printed finger) due to the change in the area between the electrodes to test the repeatability of the printed structures. As can be seen, such capacitors in most cases are characterized by a higher capacitance (changed from 0.2 pF to almost 1 pF depending on the number of fingers) after the ageing process. This phenomenon is due to the oxidation and cracking of the printed layers. The capacitance of a fingering capacitor is also affected by the relative electrical permeability of the medium. The influence of this parameter can be seen in the difference in capacitance values measured on the ceramic table (tabletop measurement) and on the strained Melinex OD film (air measurement). The capacitance of the structures measured on the tabletop was higher, which is a direct result of the difference in the effective permeability of the medium. For most ceramic materials, the relative permeability is about 7–10, while for air, it is about 1. The developed structures can be used as a part of planar electronic circuits with relatively stable parameters.

The next part of the planned research will consist of verifying the possibilities of securing ink-jet printed layer possibilities, such as the coating of the printed layers by the various materials (i.e. polymer layers) and then performing the ageing tests. Such an approach could reduce the undesirable influence of environmental conditions on the parameters of the printed layer. Moreover, the conducted research could be a base for the fabricating a novel and promising area of capacitors — supercapacitors, that could also be designed and fabricated on the flexible substrates and gives another possibilities of improving many areas, such as textronics, sustainable building design and many others.

The full paper with open access can be viewed here:

Milena Kiliszkiewicz et al 2023 Flex. Print. Electron. 8 035016; DOI 10.1088/2058-8585/acf773