This paper Solid State Polymer Multilayer Capacitors For High Temperature Application was presented by Angelo Yializis, Polycharge America Inc. USA, during the 5th Space Passive Component Days (SPCD), an International Symposium held from October 15th to 18th, 2024, at ESA/ESTEC in Noordwijk, the Netherlands. Published under permission from ESA SPCD organizers.

Introduction

High-temperature electronics are crucial across various industries, including aerospace, automotive, oil and gas exploration, and industrial power electronics.

Capacitors in these applications must maintain reliability, energy density, and stable dielectric properties even under extreme conditions.

This article presents the development and performance of NanoLam™ capacitors, which utilize solid-state polymer nanolaminate dielectric materials designed to meet stringent high-temperature demands.

Key Points

- NanoLam™ Capacitors: Designed for high energy density, superior breakdown strength, and excellent self-healing properties.

- Thermal Performance: Operational stability maintained between -196°C to 250°C with minimal capacitance fluctuation.

- Self-Healing Mechanism: Enhanced via optimized polymer chemistry with high oxygen-to-carbon (O:C) and hydrogen-to-carbon (H:C) ratios.

- Cryogenic Resilience: Capable of maintaining dielectric properties at cryogenic temperatures.

- Long-Term Stability: Demonstrates exceptional durability during extended high-voltage, high-temperature testing.

Extended Summary

The article begins by highlighting the necessity of high-temperature capacitors in environments where traditional components fail. Applications such as spacecraft re-entry, supersonic flight, and oil exploration require capacitors that can withstand fluctuating and extreme temperatures without compromising performance. Conventional capacitors like tantalum capacitors, ceramic capacitors, and polypropylene film capacitors face limitations in these environments due to stability, capacitance, and voltage constraints.

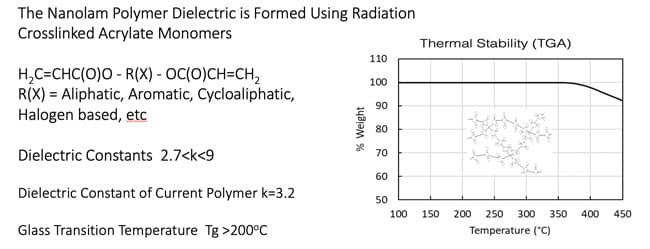

NanoLam™ capacitors address these gaps effectively. The core innovation lies in their solid-state polymer nanolaminate dielectric structure, formed with thousands of nano-thick layers. This design increases breakdown strength as the dielectric thickness decreases, a phenomenon attributed to the shorter path for charge carriers, reducing dielectric breakdown risks. The polymer used has a glass transition temperature (Tg) above 200°C, ensuring structural integrity at temperatures exceeding 160°C.

Performance tests reveal that NanoLam™ capacitors maintain exceptionally low Equivalent Series Resistance (ESR) and stable capacitance across various frequencies and temperatures. Their ESR performance surpasses that of traditional DC-link polypropylene capacitors, especially beyond 20 kHz. Moreover, as temperature increases, NanoLam™ capacitors exhibit improved capacitance and reduced dissipation factors, enhancing efficiency in high-temperature applications.

Self-healing properties are integral to capacitor longevity, especially under high voltage stress. NanoLam™ capacitors outperform conventional counterparts due to their optimized polymer composition, which facilitates effective self-repair during electrical breakdowns. Unlike metallized polypropylene capacitors, which fail after multiple self-healing events, NanoLam™ capacitors retain functionality even after extensive stress, showing less than 10% capacitance loss.

Cryogenic performance is equally impressive. Tests at -196°C (liquid nitrogen temperature) demonstrate stable dielectric behavior, with negligible changes in breakdown voltage and capacitance. This resilience makes NanoLam™ capacitors suitable for aerospace missions involving extreme cold environments.

Long-term reliability tests, conducted at voltages up to 850V and temperatures up to 160°C over thousands of hours, confirm the capacitors’ endurance. Even under prolonged stress, the changes in capacitance, ESR, and dissipation factors remain within acceptable limits. Notably, the capacitors do not require voltage derating up to 160°C, a significant advantage over traditional film capacitors.

Conclusion

NanoLam™ capacitors represent a breakthrough in high-temperature, high-reliability capacitor technology.

Their ability to maintain performance in extreme thermal environments, coupled with superior energy density, breakdown strength, and self-healing capabilities, makes them ideal for critical applications in aerospace, automotive, and industrial power systems.

The combination of advanced polymer chemistry, innovative structural design, and robust thermal stability positions NanoLam™ capacitors as a superior alternative to conventional capacitor technologies.