A new consortium funded by an award from the U.S. Department of Defense has selected Purdue University to co-lead its first project aimed at advancing the adoption of lead-free electronics in defense systems.

The Defense Electronics Consortium (DEC), to be established and managed by the U.S. Partnership for Assured Electronics (USPAE), is designed to address the defense risks created by the contraction of the U.S. electronics manufacturing sector over the last 20 years.

Purdue, the University of Maryland and Auburn University will lead the consortium’s Lead-Free Defense Electronics Project, which has received $40 million to be distributed over a period of five to seven years. Of the $3.9 million in funds for the first year of the project, approximately $1 million has been awarded to researchers at Purdue’s West Lafayette and Northwest campuses.

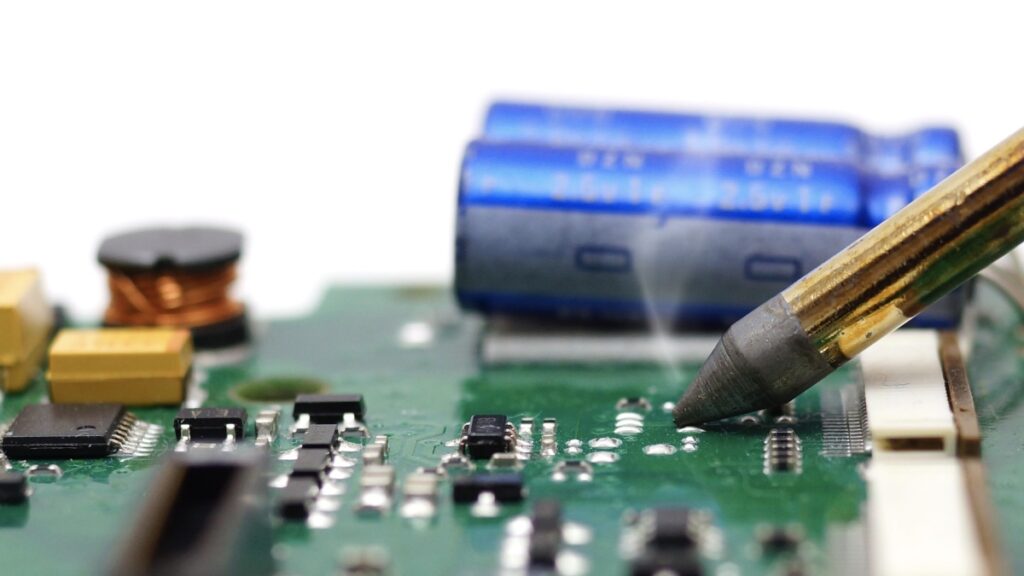

The project’s goal is to foster research and action to accelerate the transition to lead-free electronics in aerospace, defense and other high-performance electronics. Consumer and automotive electronics have been transitioning to lead-free technologies since 2006 when the European Union banned the sale of lead-containing electronics. Japan, India and China followed suit with similar bans.

“As a result of this worldwide transition, all advanced electronics are lead-free and have evolved to be used in increasingly demanding environments,” said Carol Handwerker, Purdue’s Reinhardt Schuhmann Jr. Professor of Materials Engineering and a principal investigator for the Lead-Free Defense Electronics Project.

Due to concerns about reliability, defense and aerospace companies have continued to use lead-containing electronics, lagging behind commercial sectors that have made lead-free technological advancements in compliance with lead bans. The extra manufacturing steps needed to convert these commercial electronics into leaded electronic assemblies required for defense systems costs the DoD tens of millions of dollars a year, the Pb-Free Electronics Risk Management Council estimates.

The uncertainty in how lead-free electronics perform in defense systems has limited the use of advanced electronics with improved system performance, reliability and security.

“The aim of this project is to close the gaps – quantifying the conditions where advanced lead-free electronics can and cannot be used in defense systems and guiding their implementation,” Handwerker said.

Defense electronics sales are dwarfed by consumer and industrial electronics, leading to supply-chain issues for lead-containing products that could be eliminated by the move to lead-free. The U.S. share of global production of printed circuit boards shrank from about 30% in the 1990s to less than 5% today. U.S. government reports in 2005 and 2018 warned that the trend could imperil the nation’s ability to quickly field reliable, cutting-edge defense electronics.

The COVID-19 pandemic also shined a light on the extent to which the U.S. had outsourced the manufacturing of vitally needed medical equipment with electronic components. As noted in a DoD 2021 Industrial Capabilities report to Congress, defense weapons systems and critical infrastructure could face similar supply-chain challenges if nothing is done to change course.

“This consortium will give the DoD deeper insights into the electronics industry, including how the industry supports defense missions,” said retired Rear Adm. Kevin M. Sweeney, former Pentagon chief of staff and USPAE board member. “The DEC will facilitate interactions between the DoD and the electronics industry, providing a stronger voice and greater opportunities for companies that are often buried several layers deep in the supply chain.”

The new consortium provides a vehicle for the DoD to contract with trusted partners in industry and academia, including small and medium-size innovators that typically do not do business with DoD. Purdue will be involved not only in co-leading the DEC Lead-Free Defense Electronics Project but also in identifying new opportunities for DEC to form industry-university-government teams to address high-priority defense needs.

Through a variety of programs such as conferences, networking events, white papers and collaboration projects, the DEC will tackle numerous defense electronics challenges and innovations. Participants may include companies that make printed circuit boards, microelectronics, cable harnesses, and connectors and other components, along with companies that assemble electronic systems and those that provide materials and equipment for manufacture and assembly.