Researchers from KU Leuven, Belgium in this scientific paper described how Artificial Intelligence (AI) is applied in designing highfrequency magnetic components, primarily high-frequency inductors and transformers, for power electronics systems.

Abstract

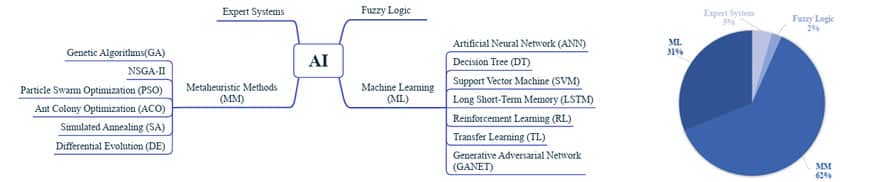

The paper provides an overview of how Artificial Intelligence (AI) is applied in designing highfrequency magnetic components, primarily high-frequency inductors and transformers, for power electronics systems. Four categories of AI, including expert systems, fuzzy logic, metaheuristic methods, and machine learning techniques, are addressed.

Firstly, AI models for estimating losses in high-frequency magnetic components are discussed. Subsequently, AI-based design methods in high-frequency inductors and transformers are observed. Then, AI tools applied to the automatic design of high-frequency magnetic components are introduced and compared.

Drawing insights from an analysis of over 200 publications, the paper highlights significant advancements: the development of AI-driven models for precise loss estimation in highfrequency magnetic components, the application of AI in optimizing design configurations for the components, and the automation of design processes. These achievements demonstrate AI’s capability to enhance the efficiency, performance, and innovation in high-frequency magnetic component design, offering a roadmap for future research in power electronics systems.

Introduction

HIgh-frequency (HF) magnetic components, such as HF transformers, HF DC inductors, and HF AC inductors, play a crucial role in a wide range of electronic systems and applications. HF magnetic components are essential for energy conversion, signal conditioning, impedance matching, resonant circuits, switching power supplies, RF communication, wireless systems, high speed data transmission. They enable efficient and reliable operation of electronic systems in various industries and applications. However, the miniaturization of magnetic components remains a challenge, as magnetics constitute a large proportion of the volume and weight and are the primary cause of power losses within a power converter.

The design of magnetic components for power electronics involves multiple objectives. One primary goal is to maximize the utilization of magnetic capabilities, enabling the achievement of multiple functions within a single component. Additionally, this design aims to minimize the size of HF magnetic components by substituting ferrites with soft magnetic materials, which offer lower power losses. These alternative materials, including iron (Fe) and various metallic elements such as silicon (Si), nickel (Ni), chromium (Cr), and cobalt (Co), offer advantages such as higher saturation points, increased permeability, and a range of options like Fe-Si alloys, powder cores, amorphous materials, and nanocrystal materials.

The key to achieving these objectives lies in the design of HF magnetic components, which heavily relies on factors such as geometric structure, excitation conditions, and magnetic properties, including power losses. These properties are crucial in determining the suitability of a magnetic core for incorporation into a component. Given their complexity and the intricate interplay between these factors, analytical modelling of these components presents significant challenges. AI provides an effective framework for tackling these intricate design aspects, by capturing nonlinear relationships and offering insights into variable interactions.

AI applications in HF inductor and transformer design share similarities in optimizing materials, geometry, and performance through predictive modelling and automated design processes. However, they differ significantly in

their focus: inductor design primarily addresses high frequency behaviour and compactness, while transformer design concentrates on efficient energy transfer, complex winding arrangements, and power applications. AI’s role in each is tailored to these specific challenges and objectives.

AI has gained substantial traction in various domains, especially in the field of power electronics. Its applications are already manifesting in optimizing heat sink designs, intelligent control systems, and energy conversion, among others. As a result, AI’s capabilities can also extend to elevating HF magnetic component design through a range of benefits, such as handling design complexities, exploring various design possibilities, and fostering innovation. These advantages collectively contribute to improving the efficiency, effectiveness, and innovation quotient of power electronics and affiliated industries.

The primary aim of this paper is to consolidate the existing knowledge in this area systematically. The contributions of this paper encompass the following aspects:

- This paper systematically investigates AI algorithms in HF magnetic components design for power electronics systems. The focus is on identifying relevant AI algorithms, their essential functions, and the corresponding applications in the HF magnetic components design field.

- Aroad mapis illustrated with the AI in HF magnetic components design.

- Comprehensive applications of AI across each category are presented, along with an in-depth discussion of the challengenges and future research directions in the field.

POTENTIAL, CHALLENGES, AND FUTURE ON AI IN HF MAGNETIC COMPONENTS DESIGN

The utilization of AI in HF magnetic components design heralds a new era of innovation, offering substantial opportunities to overcome longstanding design challenges. However, this journey is not without its hurdles. This

section delves into the promising prospects AI introduces to the field, such as comprehensive database integration and advanced loss models, while also confronting the critical issues that persist, including data integration challenges and the need for multi-disciplinary approaches. A detailed exploration of both the transformative impact of AI and the bottlenecks that must be navigated illuminates the evolving landscape of magnetic component design as follows.

- Comprehensive Database Integration: One critical challenge is the absence of a comprehensive database that integrates simulations, experimental data, and historical design examples. Such a database could serve as a valuable resource to inform and guide the development of innovative solutions. Initiatives like Powerbrain.AI, and Magnet, have begun collecting data, but AI techniques, such as Generative Adversarial Networks (GANETs), can enhance these efforts. GANETs can assist engineers in data extraction, feature extraction, data augmentation, and anomaly detection, thereby contributing to a richer database.

- AI-Assisted Loss Models: Current AI-based loss models for HF magnetic components are often limited to specific sizes or topologies. To advance this field, a comprehensive database encompassing magnetic components of varying shapes, sizes, and materials is required. AI can play a pivotal role in creating an integrated model capable of accurately predicting losses for different geometries and materials. This holistic approach will provide engineers with more precise insights into magnetic component performance.

- Thermal Design Advancements: There are few references related to thermal management for HF magnetic components design. AI holds great promise in analyzing thermal behavior, predicting areas of heat build-up, and guiding the development of efficient heat dissipation solutions like heat sinks and advanced thermal materials. AI can optimize material selection by balancing electrical and thermal performance through extensive database analysis and simulations.

- Comprehensive Optimization Design: While various AI algorithms have shown promise in enhancing the design process, they often target specific scenarios at the research level. The future of AI-based design lies in comprehensive optimization. By leveraging AI’s ability to analyze extensive and intricate datasets alongside advanced optimization algorithms, engineers can revolutionize the design process across in dustries. Collaborative efforts among AI algorithms can generate, analyze, and refine design options, fostering innovation in HF magnetic component design.

- Automatic AI Tools: Efforts like Frenetic and AI-mag aim to develop automated AI-driven design platforms that encompass the entirety of the magnetic component design process. While existing platforms offer a two-step approach to design and simulation, there is room for expanding the repository of prototypes, specifications, and data. The envisioned future entails integrating more comprehensive design methodologies into these platforms, covering the complete design journey from core/winding selection to prototype realization and specification simulation.

Challenges and future directions lie in addressing data quality, design complexity, and integration hurdles is paramount. Future research should focus on developing unified, high-quality databases, multi-disciplinary AI models, and strategies for seamless workflow integration. Enhancing AI’s scalability and generalization across different designs will be key to overcoming current limitations.

Moreover, future market time efficiency can be enhanced by facilitating rapid prototyping, automated design verification, and supply chain optimization. AI can significantly reduce the time from design to market. Adopting digital twin technology and integrating AI in manufacturing processes promise to improve procedural efficiencies, making the design process more agile and responsive to market demands.

CONCLUSION

A comprehensive review is addressed for present AI applications in HF magnetic component design for power electronics systems. AI has made significant contributions to the field of HF magnetic components design, offering innovative approaches and solutions to enhance efficiency, performance, and accuracy across various stages of the design process. The following key conclusions can be drawn from our review:

- AI can predict and quantify core and winding losses in magnetic components. This information can guide designers to select materials and geometries that minimize energy dissipation and improve overall efficiency, especially in HF applications with significant losses. As introduced above, ML models can predict material performance and behaviour under different conditions, aiding designers in making informed choices. AI-driven design techniques can assist in finding optimal magnetic core shapes and winding geometries. GA, ANN, and other optimization methods can explore a vast design space to identify configurations that minimize losses, improve coupling, and enhance efficiency.

- AI can analyse historical design data and outcomes to provide insights into trends, correlations, and patterns. This information guides designers in making informed decisions based on past experiences.

- When it comes to ML, it is essential to understand that GA, PSO, ABC, and ACO are optimization algorithms, not ML algorithms. They are used for solving optimization problems, particularly in continuous and combinatorial optimization. However,ML and optimization algorithms are not mutually exclusive. ML techniques can be combined with these optimization algorithms in various ways to enhance their performance and adaptability.

- Future opportunities and challenges are addressed for this specific field. The promising blueprints we have identified hold the potential to revolutionize HF magnetic component design further.

Read the Full Paper:

Shen, Xiaobing, Martinez, Wilmar; Artificial Intelligence Applications in High-Frequency Magnetic Components Design for Power Electronics Systems: An Overview

DO – 10.1109/TPEL.2024.3381431

IEEE Transactions on Power Electronics