Industrial robotic arms are increasingly expected to operate continuously in hot, cramped and vibration‑intensive environments while remaining compact and energy efficient. Panasonic’s latest application insight highlights how its portfolio of conductive polymer capacitors, metal composite power inductors and advanced chip resistors can help design engineers address these constraints in factory automation and robotics.

The focus is on enabling durable, miniaturized, thermally robust power and control electronics inside articulated robot arms and related industrial automation equipment.

Key Takeaways

- Panasonic focuses on passive components for robotics, highlighting capacitors, inductors, and resistors that enhance efficiency and durability.

- Their conductive polymer capacitors provide low ESR and stable capacitance, suitable for high-duty applications in robotic arms.

- Metal composite power inductors maintain stable performance in high temperatures and vibrations, ideal for compact designs.

- Panasonic’s advanced chip resistors target current sensing in harsh environments, using materials resistant to sulfur and high temperatures.

- Design-in guidelines emphasize selecting components based on specific robotic application needs, enhancing reliability and performance.

Key features and benefits

Panasonic positions conductive polymer and hybrid aluminum electrolytic capacitors as alternatives to traditional MLCC and aluminum electrolytic solutions where DC bias, temperature drift and limited lifetime are problematic in robotic power electronics. These capacitors offer low ESR and stable capacitance over temperature and applied DC voltage, reducing part count, mounting area and potentially total implementation cost in DC link, decoupling and filtering stages. The vendor also emphasizes vibration‑resistant capacitor variants rated up to 30G, metal composite power inductors with high saturation current and low AC resistance, and chip resistors optimized for low ohmic values, sulfur resistance and extended high‑temperature operation in harsh industrial environments.

For designers tasked with miniaturizing robot joints and end‑effectors, these characteristics translate directly into board space savings, simplified mechanical reinforcement and improved thermal margins. Purchasing teams benefit from series specifically qualified through extended life and vibration testing, which can reduce field failure risk and total cost of ownership in high‑duty industrial robots.

Typical applications

Robotic arms combine high‑power actuators, precision motion control, sensing and communication, all packed into limited volumes and often mounted on moving, vibrating structures. Within such systems, Panasonic’s conductive polymer capacitors and polymer hybrid aluminum electrolytics are suitable for:

- DC link and intermediate bus smoothing in servo drives and inverters located in the arm or base

- Local bulk decoupling for high‑current motor drivers, gate drivers and control MCUs

- Output filtering in point‑of‑load regulators supplying logic, sensors and communication modules

Metal composite power inductors are positioned for power conversion paths exposed to high ripple currents and elevated temperatures:

- Step‑down converters for distributed 24 V or 48 V industrial bus systems feeding robot joints

- Input/output chokes in EMC filters and LC filters for industrial and automotive‑style supplies

- Inductor positions where mechanical vibration and heat shock are critical, such as embedded drives near motors

Low‑ohmic current sense chip resistors and anti‑sulfur resistor series are targeted at sensing and protection circuits inside robots:

- Current measurement in motor phases, DC bus rails and auxiliary supplies

- Shunt resistors in power distribution monitoring and safety circuits exposed to high currents

- General signal and bias networks in environments with sulfur contamination, lubricants or elevated ambient temperature

Technical highlights

Capacitors for miniaturization and harsh conditions

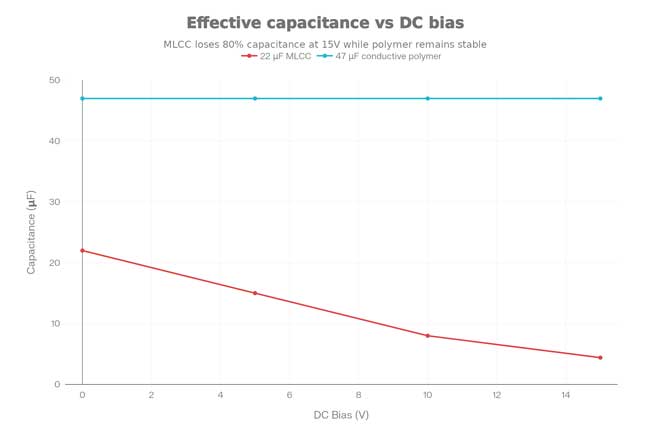

A key argument in the press material is the contrast between MLCC behavior and conductive polymer capacitors under DC bias and temperature. For an MLCC with a nominal capacitance of 22 µF, the example shows an 80% capacitance reduction at 15 V DC, combined with an additional approximate 10% reduction at high and low temperatures. Under those conditions, only about 20% of the nominal capacitance remains effective, meaning that more than ten 22 µF MLCCs may be required to guarantee 47 µF effective capacitance in a given robotic circuit.

Switching to a single 47 µF conductive polymer capacitor eliminates this derating behavior, enabling a one‑to‑one capacitance design and significantly reducing component count and PCB area.

For high‑temperature, long‑life applications in industrial robotics, Panasonic highlights several polymer capacitor series:

- Aluminum Polymer Electrolytic Capacitors (SP‑Cap): specified with an operational life up to 5,500 hours at 135 °C, suitable for high‑load, high‑temperature points such as compact servo drives and motor control boards.

- Polymer Tantalum Capacitors (POSCAP): guaranteed up to 1,000 hours at 125 °C, offering high capacitance in downsized B case packages and enabling replacement of MnO₂ tantalum types with improved safety behavior according to manufacturer datasheet.

- Aluminum Polymer Solid Capacitors (OS‑CON): lifetimes up to 20,000 hours at 105 °C, with the OS‑CON SVT series reaching an expected life of around 12.8 years at 90 °C, making them attractive where long robot service life and minimal maintenance are required.

Across these series, the use of conductive polymer electrolyte results in significantly lower ESR compared with general aluminum electrolytic and tantalum capacitors, which supports lower ripple, reduced heating and allows fewer parts in parallel to handle the same current.

| Series | Technology | Typical use in robots | Lifetime / temperature example* |

|---|---|---|---|

| SP‑Cap | Aluminum polymer electrolytic | DC/DC input/output, bulk decoupling | Up to 5,500 h at 135 °C |

| POSCAP | Polymer tantalum | Space‑constrained high‑capacitance nodes | Up to 1,000 h at 125 °C |

| OS‑CON | Aluminum polymer solid | Long‑life, high‑ripple positions | Up to 20,000 h at 105 °C; SVT ~12.8 y @90 °C |

| Hybrid | Polymer hybrid aluminum electrolytic | DC link, smoothing in vibrating locations | Vibration‑resistant versions up to 30G |

Vibration‑resistant capacitors for robotic arms

Robotic arms are exposed to continuous motion and shock, particularly in joints where power electronics may be co‑located with motors and gearboxes. Panasonic addresses this with conductive polymer hybrid aluminum electrolytic capacitors, including versions specifically marketed as vibration‑resistant. These components can withstand vibration acceleration up to 30G over a diameter range of approximately 6.3 mm to 10 mm, according to the press material. In many designs, this robustness can eliminate the need for additional bonding or adhesive reinforcement around capacitors, simplifying assembly processes and reducing rework risks.

Hybrid capacitors in this class also support larger capacitance and higher ripple current handling than conventional aluminum electrolytics in similar sizes, while offering improved ESR and temperature performance. This makes them suitable for DC link and smoothing roles directly on drive PCBs embedded in moving robotic structures.

Metal composite inductors for efficient power conversion

Panasonic’s metal composite (MC) power inductors use a proprietary composite magnetic core and an integrated molding structure. The three main technical areas:

- Magnetic saturation characteristics and temperature stability: MC types are contrasted with ferrite inductors, which tend to show sharp inductance drops under DC bias, especially as temperature rises. Example curves under 25 °C, 100 °C, 125 °C and 150 °C illustrate how ferrite parts lose inductance more abruptly with increasing DC current, whereas MC inductors maintain inductance more gradually over current and show minimal temperature dependence. For power stages in robots that run hot, this behavior helps maintain stable inductance, current ripple and control loop response.

- Heat and vibration resistance: MC inductors are tested for heat shock from −40 °C to 150 °C over 2,000 cycles and for continuous heat resistance at 150 °C for 2,000 hours, aligning them with stringent automotive‑grade expectations. This robustness makes them suitable for installation close to motor windings or in other thermally stressed parts of robotic arms.

- Low AC resistance (ACR): at higher switching frequencies, skin and proximity effects increase conductor resistance. The release describes comparison data showing that the ACR rise with frequency is smaller for MC inductors than for ferrite types, which lowers AC losses and heat generation. In high‑frequency DC‑DC converters and LC filters used in robotics, lower ACR contributes to higher efficiency and less self‑heating of the power stage.

For design engineers, these attributes mean that MC inductors can often enable higher switching frequencies or higher currents within the same footprint, which is valuable when space is limited inside compact robot modules.

Inductor behaviour summary:

| Property | Ferrite inductor (general) | Metal composite inductor (Panasonic) |

|---|---|---|

| Inductance vs DC bias | Steep drop at higher currents | More gradual drop, more stable over current |

| Temperature dependence | Larger inductance change vs temperature | Smaller change from 25 °C to 150 °C |

| AC resistance vs freq. | Increases rapidly with frequency | Slower increase, lower loss at high frequency |

| Thermal / vibration | Standard industrial ratings | Tested to −40…150 °C, 2,000 cycles/2,000 h |

Generally, ferrite types are known for their pronounced saturation characteristics, as indicated by the graph, where inductance sharply decreases with increased DC bias and also varies with temperature. In contrast, Panasonic’s MC type does not exhibit a rapid decrease in inductance, indicating saturation, and shows minimal variation with temperature. This is a crucial point for power inductors, which are accompanied by heat generation.

Panasonic’s MC type inductors ensure high reliability, high vibration resistance and are suitable for automotive applications, undergoing rigorous reliability testing. Heat shock: -40°C ⇔ 150°C for 2,000 cycles, and heat resistance at 150°C for 2,000 hours are guaranteed. Below are standard automotive test items and conditions.

| Test item | Condition | Test count / time | Judgment criteria |

|---|---|---|---|

| Heat shock test | −40 / +150 °C (each 10 minutes) | 2000 cycles | L value should be within ±10% of the original value. |

| Vibration test | 10G (5 Hz – 2 kHz) | XYZ (each 4 hours) | DCR is within ±5% of the original value. |

| Vibration test | 30G (5 Hz – 2 kHz) | XYZ (each 4 hours) | Insulation resistance shall be 10 kΩ or higher. |

| High‑temperature life test | 150 °C, DC rated A | 2000 hours | No abnormality can be detected in the appearance and structure. |

| Temperature‑controlled life test | 85 °C / 85% RH, rated current | 2000 hours | There shall be no wire breakage or mechanical damage. |

| Cold resistance test | −40 °C | 2000 hours | There shall be no wire breakage or mechanical damage. |

AC Resistance

When the frequency of the current flowing through a conductor increases, the skin effect and proximity effect cause the current to concentrate on the surface of the conductor, resulting in lower density in the center and higher density on the surface. Consequently, the resistance component increases at high frequencies, and in inductors, this increased resistance component is referred to as AC resistance (ACR).

The graph below compares the AC resistance (ACR) of MC-type and ferrite-type inductors. As the frequency increases and ACR rises, AC losses increase, leading to higher heat generation. As indicated by the graph, the increase in ACR for the MC type is smaller than that for the ferrite type, indicating lower losses and heat generation even at high frequencies.

Advanced chip resistors for sensing and harsh environments

The press release presents several resistor technologies tailored for current sensing, sulfur‑rich atmospheres and high‑temperature operation.

For current detection, Panasonic offers chip resistors with very low resistance values, enabling reduced power loss in shunt applications. An illustrative example shows that when 4 A flows through a 10 mΩ shunt resistor, the associated heat rise is significantly higher than through a 2.5 mΩ shunt; lowering the resistance can reduce the temperature by about 33 °C in the given scenario. Engineering measures contributing to these low values include forming resistive elements on both sides of the substrate and using a long‑side electrode layout, as well as shifting from AgPd to CuNi alloy resistive materials with lower resistivity.

Anti‑sulfur chip resistors are recommended for environments where sulfur compounds can attack silver‑based electrodes, such as near volcanoes, hot springs, high‑traffic roads, industrial machining areas and even general equipment containing lubricants, rubber seals, fan motors or silicone coatings. Panasonic’s approach replaces conventional silver electrodes with materials that are more sulfur‑resistant and offers two main series:

- ERJS series: uses gold‑based electrodes aimed at achieving “absolute performance” in sulfur‑rich environments, showing no measurable resistance change after 3,000 hours of sulfur immersion testing according to the press data.

- ERJU series: uses high‑palladium silver‑palladium alloy electrodes to suppress silver diffusion. In the cited sulfur‑immersion test, these parts avoid disconnection even after 3,000 hours, where typical electrodes fail after about 100 hours, and are designed for exposure beyond 12,000 hours.

For high‑temperature operation, Panasonic’s ERJH series chip resistors are specified up to 175 °C maximum operating temperature. Standard chip resistors often limit operation to about 155 °C and require power derating starting around 70 °C ambient. ERJH devices shift the derating start to 105 °C, supporting sustained higher dissipation in hot control cabinets, in‑arm electronics or near power components.

| Series | Key feature | Typical use in robots | Noted characteristic example* |

|---|---|---|---|

| Low‑R | Very low ohmic values | Current sensing in motor phases / DC bus | Example: 4 A, 10 mΩ → 2.5 mΩ reduces heat by ~33 °C |

| ERJS | Gold‑based anti‑sulfur | High‑sulfur environments, long‑life systems | No resistance change after 3,000 h sulfur immersion |

| ERJU | High‑Pd AgPd anti‑sulfur | Cost‑sensitive anti‑sulfur applications | Avoids disconnection beyond 3,000 h immersion |

| ERJH | High‑temperature thick‑film | Hot zones up to 175 °C, sealed enclosures | Derating starts at 105 °C instead of ~70 °C |

Design‑in notes for engineers

From a design‑in perspective, several guidelines for selecting passive components in robotic applications include:

- Evaluate DC bias and temperature effects of MLCCs versus polymer capacitors early in the design. For DC link and bulk decoupling roles requiring stable high capacitance at operating voltage and temperature, conductive polymer capacitors can replace arrays of MLCCs, simplifying layouts and mounting while improving effective capacitance and ESR behavior.

- For embedded drive electronics inside robot joints, consider vibration‑resistant hybrid aluminum electrolytic capacitors where board‑level reinforcement would otherwise be needed. This can reduce manufacturing steps such as adhesive application and manual inspection, especially under 30G‑class vibration conditions described in the press information.

- In switching power stages, metal composite inductors with flatter saturation curves and lower ACR can support higher switching frequencies and higher output currents without excessive heating or loss of inductance. When designing for high ambient temperatures, the extended heat shock and high‑temperature tests listed for MC inductors provide clues to their long‑term robustness.

- For current sensing in motor phases or DC bus rails, low‑ohmic current detection resistors with CuNi‑based elements can materially improve thermal performance compared with higher ohmic shunts. Careful layout around such shunts remains important to avoid hot spots and to ensure accurate Kelvin sensing.

- Where equipment may be exposed to sulfur‑containing environments or uses lubricants, rubber components and silicone conformal coatings, anti‑sulfur resistor series such as ERJS or ERJU should be preferred over general‑purpose chip resistors to mitigate sulfuration‑induced open circuits.

- In high‑temperature zones or sealed enclosures, heat‑resistant resistor series like ERJH allow designers to maintain higher power ratings up to 105 °C ambient and to meet reliability targets at temperatures up to 175 °C without excessive derating margin.

Panasonic also promotes several online tools that support design‑in: a characteristic viewer that plots frequency and temperature behavior of selected parts, an LC filter simulator for industrial and automotive filters using Panasonic inductors and capacitors, and a lifetime calculation tool for hybrid and aluminum electrolytic capacitors. These tools help engineers predict component behavior in realistic robot operating profiles and fine‑tune their selections before hardware builds.

Conclusion

Panasonic’s portfolio of conductive polymer capacitors, metal composite inductors and specialized chip resistors provides a coherent set of options for designing compact, thermally robust and vibration‑tolerant electronics in industrial robotic arms.

By understanding the DC bias, temperature and environmental behavior of these components at series level and then refining choices with datasheets and simulation tools, design engineers and purchasers can align component selection with long‑term reliability and maintenance targets in demanding factory automation installations.

FAQ: Passive components for robotic arms

Conductive polymer capacitors offer stable capacitance over temperature and DC bias, combined with low ESR and high ripple current capability. This allows designers to replace large MLCC banks with fewer parts, saving PCB area and improving reliability in compact servo drives and control boards.

Metal composite power inductors show flatter inductance versus current curves and lower AC resistance than typical ferrite parts. They also withstand high temperatures and vibration, which helps maintain converter efficiency and stable control in robot joints and industrial drives.

Anti-sulfur chip resistors use sulfur‑resistant electrode systems to prevent open circuits caused by sulfur contamination from exhaust gases, lubricants or rubber parts. They are recommended for robot controllers and power modules operating in harsh factory or outdoor environments where standard resistors may fail over time.

High‑temperature series are suitable when ambient temperatures can reach above 125 °C or when self‑heating is significant, such as near power stages or inside sealed enclosures. Their higher maximum operating temperature and later derating onset provide more margin for continuous high‑power operation.

Key series include SP‑Cap, POSCAP and OS‑CON polymer capacitors, conductive polymer hybrid aluminum electrolytic capacitors, metal composite power inductors, low‑ohmic current sense resistors, anti‑sulfur ERJS and ERJU resistors, and high‑temperature ERJH resistors. Together they address miniaturization, thermal robustness and long‑term reliability requirements in industrial robotic applications.

How to select passive components for a robotic arm design

- Define electrical and environmental requirements

Start by listing bus voltages, current levels, switching frequencies and required ripple limits for each power stage. Add expected ambient temperatures, hot‑spot temperatures, vibration levels and any risk of sulfur exposure or contamination in the robot’s operating environment.

- Evaluate capacitor technology for bulk energy storage

Compare the number of MLCCs needed after DC bias and temperature derating with conductive polymer options such as Panasonic SP‑Cap, POSCAP or OS‑CON. Prefer polymer or hybrid aluminum electrolytic capacitors where they can replace large MLCC arrays, reduce ESR and fit within mechanical constraints.

- Choose vibration‑tolerant and thermally robust parts

For electronics located in robot joints or near motors, select vibration‑resistant hybrid capacitors and metal composite inductors tested for high G‑levels and extended high‑temperature operation. Check lifetime and vibration data in the datasheets to match them with the robot’s expected duty cycle and maintenance intervals.

- Size metal composite inductors for efficiency

Use inductance‑versus‑current and AC resistance curves for inductors, consider to choose metal inductors and its parameter values that keep ripple within limits at the target switching frequency. Ensure that saturation current and temperature ratings exceed peak load and worst‑case thermal conditions in the arm.

- Select current sense and protection resistors

For shunt measurement, use low‑ohmic current detection chip resistors that minimize power loss while still providing adequate measurement resolution. In areas exposed to exhaust gases, lubricants or rubber components, specify anti‑sulfur resistor series, and use high‑temperature parts where ambient and self‑heating are critical.

- Verify lifetime and reliability with tools

Validate selections using online lifetime calculators, characteristic viewers and LC filter simulators where available. Confirm that the resulting component stress levels and calculated lifetimes match system‑level reliability targets before finalizing the bill of materials.

Source

This article is based on an application insight press release from Panasonic Industry Europe describing how its passive component portfolio supports reliability, miniaturization and energy efficiency in industrial robotic arms and factory automation systems.

References

- Panasonic Industry Europe – Revolutionizing reliability and efficiency in robotic arms

- Panasonic SP‑Cap aluminum polymer electrolytic capacitors – family overview

- Panasonic POSCAP polymer tantalum capacitors – family overview

- Panasonic OS‑CON polymer capacitors – family overview

- Panasonic Characteristic Viewer design tool

- Panasonic Industrial/automotive LC filter simulator

- Panasonic Lifetime Calculation Tool for Hybrid/Aluminum Electrolytic capacitors