This article elaborates on design and calculation of buck DC/DC converters. The post is based on Würth Elektronik‘s “DC/DC Converter Handbook” that can be ordered from WE website here. Published under permission from Würth Elektronik.

Key Takeaways

- The article discusses Buck Converter Design based on Würth Elektronik’s DC/DC Converter Handbook.

- It emphasizes minimizing high ΔI/Δt loops and the hot node area for better efficiency.

- Proper selection of input/output capacitors and inductors is crucial for ripple and EMC compliance.

- Simulation tools like REDEXPERT help simplify component selection.

- Designing input and output filters is essential to meet EMI/EMC standards while maintaining performance.

Buck Converter Block Diagram and General Thoughts

Among the switched-mode power supplies (see DC-DC Converter Basic Characteristics and Formulas), the buck converter (step-down converter) is certainly the most widely used topology. The buck converter is basically nothing more than a square wave generator with a downstream LC filter.

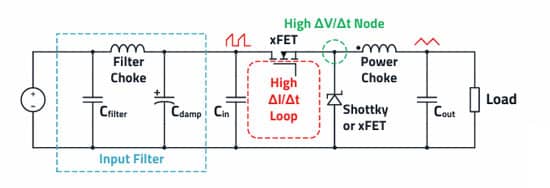

It is obvious at first glance that, with regard to EMC, more attention must be paid to the input side than to the output side. From a functional perspective, “only” one capacitor is required at the input. This capacitor buffers the charge necessary for the current during the switch-on phase of the high-side FET and is recharged by the source during the switch-off phase.

If this converter is now placed at the input of the entire device electronics (e.g., Vin = 24 V) then further precautions must be taken regarding interference emission (EN 55032) and interference immunity (EN 55035). Even a suitably selected and well placed input capacitor is not sufficient to buffer the sometimes very high discontinuous currents over a wide frequency range.

As apparent in figure 3., a current loop (H-field loop antenna) with a very high ΔI/Δt results at the input of the buck converter.

Thus, even the smallest parasitic inductance of the input capacitor (ESL) and circuit board layout can lead to unwanted RF voltages up to over 200 MHz. This is one major cause of differential mode interference. For this reason, a compact layout, the appropriately selected capacitor technology (aluminum polymer capacitors or MLCC ceramic capacitors) as well as a correctly designed input filter are essential for success. The compact layout also minimizes the radiated field via the undesirable conductor loop (H-field loop antenna).

A filter may also be required at the output of the buck converter if, for example, the residual ripple of the output voltage must be particularly low.

There is the “hot node” – marked green in the block diagram – at the connection of the source terminal of the internal or external high-side MOSFET and the cathode terminal of the diode, or in case of a synchronous buck, the drain terminal of the second MOSFET. The switched input voltage can be measured in full amplitude at this point. The switching voltage has a particularly high ΔV/Δt here, creating an undesirable E-field antenna.

The conductor traces and copper surfaces of the PCB together with the PCB material used (e.g., FR4) give rise to undesirable parasitic capacitances. An RF current flows to the reference ground via these coupling capacitances. This current is the main cause of common-mode interference, which appears in EMC measurements. Therefore, it is important to minimize the area of this point in the layout.

The “dot” mark on the storage inductor is the start of the (inside) winding and should be aligned or connected toward the “hot node”. This helps to keep the geometric area of this critical structure around the “hot node” and thus the parasitic capacitance, as well as the resulting E-field antenna structure, as small as possible.

Buck Converter Layout Considerations

In the layout of a buck converter, it is therefore important to keep the loops with a high ΔI/Δt, as well as the geometric area of the “hot node” with its high ΔV/Δt, as small as possible.

As apparent in Figure 1.30, the “single point“ ground reference for the power ground is the way to success. If the configuration of the input capacitor, the output capacitor, the diode, and the IC are placed skillfully, the ground pads of these components meet at just one point. This minimizes undesirable H-field loops as well as parasitic inductances as much as possible.

If an input filter is used, it should be placed some distance away from the buck. As a result, the ground reference of the filter capacitors stays largely quiet and the risk of direct field coupling into the filter components is reduced. The individual filter components (in this case, filter inductor and filter capacitor) should always be configured at 90° to each other; this avoids unfavorable coupling and provides a wideband filter effect.

To further reduce the potential noise from a high ΔI/Δt, it is essential to place the input capacitor very close to the Vin pin (drain connection of the internal or external high-side MOSFET) of the buck regulator.

In combination with the “Single Point PGND” ground reference, a very small current loop is obtained and therefore also a small parasitic H-field loop (loop antenna). A very high ΔI/Δt also occurs in the bootstrap circuit. Therefore, it is important to place the bootstrap capacitor directly at the associated buck regulator pin.

To keep undesirable output voltage fluctuations low, the feedback resistor network should also be placed close to the regulator. The possibly very long feedback trace therefore has a low impedance and is less sensitive to interference. The output voltage for regulation should be tapped at a point as close to the output capacitor as possible.

To transfer theory into practice, here is a sample calculation:

Example Buck Converter Design and Calculation

storage inductor of an asynchronous buck converter

Input voltage: Vin = 12 V nominal

Output voltage: Vout = 3.3 V

Output current: Iout = 1 A max.

Switching frequency: fsw = 500 kHz

Max. bandwidth control loop/crossover frequency: fc = 10 kHz

Forward voltage rectifier diode: VD = 0.4 V

Ripple current factor: r = ΔI/Iout ≈ 0.35

Duty cycle D:

Minimum inductance necessary to maintain ripple current factor:

Considering a standard inductance value of 15 µH, this results in a ripple current of:

Rated Current Ir:

Often it is sufficient to select the rated current based on the average inductor current (output current at the buck converter) with some margin. In fact, the RMS value of the inductor current (average inductor current + AC ripple current) is responsible for the heat generated at the DC resistor (see RMS chapter in Selection of Storage Inductors for DC/DC Converters).

A choke with more than 1 A rated current (according to datasheet) should be selected.

Saturation Current Isat:

Half the AC ripple current must be added to the average inductor current to determine the maximum peak current. The average inductor current of the buck converter corresponds to the output current.

Now a suitable storage choke based on these results can be selected. Some safety margin should also be included, as component tolerance and ambient temperature have been neglected here. For this example, an experienced designer selects an inductor with at least 15 µH according to the datasheet, as well as 1.1 A rated current and 1.5 A saturation current.

The fastest and easiest way to get there is to use the REDEXPERT inductor simulation tool.

Input Capacitor for a Buck Converter

RMS current (ripple current) through the input capacitor:

With the help of the REDEXPERT tool, a capacitor can now be selected with the lowest possible impedance at the switching frequency of 500 kHz, which at the same time meets the requirements in terms of ripple current as well as voltage.

Output Capacitor for a Buck Converter

The output capacitor is defined based on the maximum permissible voltage ripple and based on the maximum permissible voltage change (Vdroop) resulting from a load step. In our example, we want to allow a maximum of 1% residual voltage ripple, i.e., 33 mV at an output voltage of 3.3 V and only 3% voltage dip, corresponding to 99 mV, at a load step (Istep = 0.5 A) from 0.5 to 1 A.

From these assumptions, the minimum necessary capacitance can be calculated, which fulfills both requirements. For the output voltage residual ripple, in addition to the capacitance-dependent part, the influence of the ESR is considered (the ESL is neglected). For simplicity, an even split is assumed for the two components, resulting in 16.5 mV each for the capacitance and the ESR calculations.

In addition, it must be checked mathematically whether the AC current through the output capacitor stays below the maximum ripple current according to the data sheet.

The following equation describes the relationship between the output capacitance and the ripple voltage for a buck converter topology (assumption: ideal capacitor):

The next equation is used to calculate the minimum capacitance required for the given capacitance dependent ripple:

The next equation describes the relationship between the ESR of the output capacitor and the ripple voltage for a buck converter topology (assumption: ESL is neglected):

This equation is used to calculate the maximum allowable ESR of the output capacitor based on the given ESR-dependent ripple voltage:

This equation is used to calculate the minimum output capacitance to maintain a given voltage droop during a load step:

The next equation is used to determine the RMS current that flows through the output capacitor of the buck converter:

The capacitance of 5.2 µF for the maximum defined voltage ripple is not relevant in this case, as the minimum necessary capacitance of 80.4 µF results from the maximum allowed voltage change during load transients. Based on the calculated results, we therefore need a capacitor with at least 82…100 µF (standard values).

The ESR could be higher than 4.7 mΩ since the capacitance-dependent part of the ripple is lower due to the higher capacitance value. An H-chip polymer SMT capacitor, such as the WCAP-PHLE (875035019001), would be a suitable choice for this purpose. This offers a stable capacitance of 100 µF in a very small package (7.3 · 4.3 · 1.9 mm³), a 3.5 mΩ low ESR at 500 kHz and it is specified for a ripple current of up to 6.3 A.

Design of the Input Filters for a Buck Converter

The switching regulator operates at 12 V and 500 kHz. In chapter 1.4.2 it was mentioned that it makes sense to design the cut-off frequency of the LC input filter to 1/10 of the switching frequency. This provides about 40 dB attenuation for the fundamental wave (switching frequency).

A 22 µF/25 V/MLCC or polymer (advantage of polymer = stable capacitance, no DC bias effect as with class 2 MLCCs) type is specified as filter capacitor. The following formula can now be used to calculate the necessary filter inductance.

The next possible default value, 1.5 µH nominal, is selected. The rated and saturation current of the filter inductor should be approx. 20…40% above the maximum DC input current of the converter.

Design of the Output Filters for a Buck Converter

In some applications, there is the necessity to filter the output again. Like at the input of the converter, an LC filter with a small inductance is suitable for this purpose. Alternatively, or additionally, a pulse current-resistant multilayer power suppression ferrite WE-MPSB can be used.

The calculation is carried out in the same way as for the input filter. Due to the higher current at the output of a buck converter, the filter inductance should remain as small as possible in relation to the filter capacitor (e.g., 1:10 ➔ 1 µH : 10 µF) to keep the efficiency as high as possible.

Important: The feedback tap of the output voltage for the control loop must still take place at the actual output capacitor, and not at the filter capacitor! But there are applications, especially for high current PoL buck converters, where the voltage drop across the filter inductance cannot be ignored. In this case, the feedback tap must be after the filter inductance, so the voltage drop, due to the RDC, can be readjusted. Special restrictions apply to this circuit version, which are described in more detail in Application Note ANP044 “Impact of the layout, components, and filters on the EMC of modern DC/DC switching controllers“ (www.we-online.com/ANP044).

Read also the related articles in this series:

- Selection of Capacitors for DC/DC Converters

- Selection of Storage Inductors for DC/DC Converters

- Input filters for DC/DC converters

- Switching vs Linear Power Converters Compared

- SEPIC Converter Design and Calculation

- Boost Converter Design and Calculation

- Flyback Converter Design and Calculation

- Fly-Buck Converter Explained and Comparison to Flyback

- LLC Resonant Converter Design and Calculation

Buck and Boost Converter Basic Formulas

The following table 1. provides basic formulas of the buck and boost converter topologies.

1) These assumptions apply to the ideal switching regulator in continuous conduction mode

(CCM), i.e., the efficiency of the converter is assumed to be 100% (η = 1).

2) The current curve from this equation is approximately rectangular (ΔI neglected). Exactly:

3) The equations defined for ΔVC,out apply to the ideal capacitor. Cout therefore defines the minimum capacitance to meet the ripple voltage requirement. The actual voltage ripple will be higher due to the parasitic inductance ESL (equivalent series inductance) and ESR (equivalent series resistance) of the capacitor.

FAQ: Buck Converter

A buck converter steps down a higher DC input voltage to a lower DC output voltage with high efficiency, making it ideal for regulated power supplies.

Improper layout can increase parasitic inductance and capacitance, leading to EMI issues, voltage ripple, and reduced efficiency. Compact loops and minimized hot node areas are essential.

The output capacitor must balance capacitance and ESR to control ripple voltage and transient response. In the example, at least 82–100 µF with low ESR was required for stable operation.

How to Design a Buck Converter

- Define Requirements

Set input voltage, output voltage, current, and switching frequency.

- Calculate Duty Cycle

Use the ratio of output to input voltage to determine duty cycle.

- Select Inductor

Choose inductance to maintain ripple current factor (e.g., 15 µH for 12V→3.3V, 1A).

- Choose Capacitors

Input capacitor must handle ripple current; output capacitor must meet ripple and transient response requirements.

- Optimize Layout

Minimize hot node area, place input capacitor close to MOSFET, and use single-point PGND.

- Design Filters

Add LC filters at input/output if EMC or ripple requirements demand it.

- Validate with Simulation

Use tools like REDEXPERT to confirm component ratings and performance.