source: Electropages article

Keysight Technologies’ Giovanni D’Amore explains six methods of measuring this vital material characteristic.

Have you heard of dielectric properties? If you have, you’re probably thinking back to charge storage experiments you did in physics lessons at school. You might also have come across them when analysing the way dielectric materials affect a capacitor’s characteristics. But, contrary to their perceived niche status, dielectric properties are important in many ways across many sectors. It’s therefore vital to be able to measure them accurately.

Below, we’ll outline a range of use cases, and look at six ways to measure dielectric properties, explaining when you might use each one.

Dielectric properties: a breadth of use cases

We’ve already established that dielectric properties are important in the electronics industry when it comes to capacitor performance. Electronics engineers are also interested in dielectric properties of substrates, and the printed circuit boards (PCBs) they create with them. Furthermore, dielectric properties play a role when making antennas using PCB traces, when creating ‘phantom’ materials for systems that measure specific absorption rates, when working with absorbers, and when managing the propagation of electromagnetic fields by applying ferrite materials.

Those working in defence and aerospace will also be concerned with dielectric properties, particularly when it comes to developing stealth technology, radomes and materials that absorb radiation.

Across various industries, manufacturers need ways of characterising materials. This includes composite and ceramic materials for car parts; plastics and polymers for insulation, films and fibres; hydrogels used in soft contact lenses and nappies; and liquid crystal found in displays.

In the food sector, dielectric properties are an important measurement technique, used in the creation of microwaveable food when researching spoilage, moisture and packaging.

In forestry, dielectric measurements are used to identify how much moisture is contained in wood and paper, while in mining, they help analyse the contents of oil.

Elsewhere, these properties are used in the pharmaceutical industries to support drug research and manufacturing. Human tissue characterisation, fermentation and biomass system design and bio-implant research are all areas that take advantage of the technique.

Measuring dielectric properties

There are different ways to measure dielectric properties, with each using precise instruments, fixtures to hold the material under test (MUT) and software that helps you measure complex permittivity and permeability factors, and then shows the results.

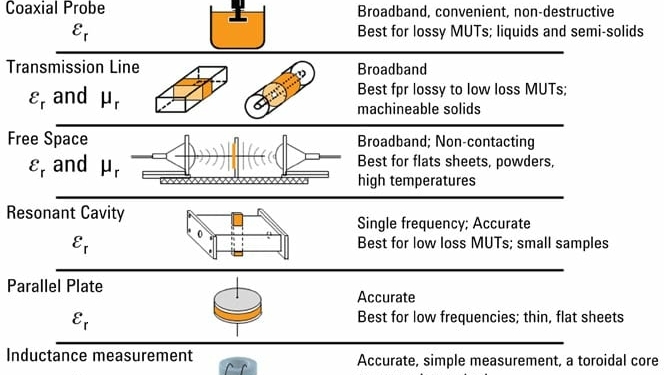

There are a range of products in this space, including impedance analysers, network analysers and LCR meters able to deliver accurate results when you apply frequencies up to 1.5 THz. Complementing these are fixtures that enable you to use the coaxial probe, coaxial/waveguide transmission line, free space, resonant cavity and parallel plate measurement techniques, which are shown in Figure 1 and described further below.

So how do these measurement techniques work, and when might you use them?

Coaxial probe method

This technique is best for semi-solid materials (powders) and liquids. It’s non-destructive, straightforward and only requires a single measurement. A typical coaxial probe measurement system is made up of a network or impedance analyser, coaxial probe and appropriate software.

Choose your analyser and probe based on your measuring frequency, though the overall range is between 10M Hz and 50 GHz. You can also get probes that can withstand temperatures from -40°C to +200°C. These can be produced with a big flange, meaning you can also measure flat solid materials. There are slim probes available too, which are particularly helpful for taking measurements in chemical reaction chambers, fermentation tanks and other environments with small openings. For the medical, chemical and food sectors, there are high-performance probes that blend many of the above characteristics with the ability to be sterilised in an autoclave.

Transmission line method

This broadband technique is designed for machinable solids. The MUT sits within an enclosed transmission line, and the frequency coverage is primarily restricted by the size of the sample holder.

Free space method

This non-contact technique uses antennas to direct microwave energy through or on to a material. You can use this method at high temperatures and at millimetre-wave frequencies.

Resonant cavity method

A resonant cavity is a high Q structure that will resonate at particular frequencies. When you introduce the MUT, this impacts on the centre frequency and Q factor of the cavity. This enables you to calculate its permittivity. Keysight makes a range of resonators, including the 85072A 10-GHz split-cylinder resonator and split-post dielectric resonators.

Parallel-plate capacitor method

This is the technique you might remember from school physics lessons. You create a capacitor by sandwiching a thin piece of your material between two electrodes. The parallel-plate capacitor method is ideal for achieving accurate, low-frequency measurements of liquids or thin sheets of material, typically using an impedance analyser or LCR meter.

Inductance measurement method

Finally, there’s the inductance measurement method, which measures a material’s inductance as though it were a toroidal core, thereby enabling you to derive its permeability. You wrap wire around the MUT and evaluate its inductance with respect to the wire ends. Keysight’s 16454A magnetic material test fixture is a good structure to use with single-turn inductors, because it won’t leak flux when you put a toroidal core into it.

The figure below shows the different testing approaches and types of fixture against the materials you’re testing and your measurement frequency.

Supporting software

Interpreting dielectric measurements as permeability and permittivity measurements can sometimes be difficult, but you can make your life easier by using software such as Keysight’s N1500A materials measurement suite. This helps you work with a network analyser, and guides you through the testing process, from set-up and measurement to transforming the resulting S-parameter data into the formats you require.

Because it works with a range of measurement techniques and mathematical models, the software can be used in most situations. You can also use it to model potential interactions between the MUT and the fixture, enabling you to extract bulk material properties.

The screenshot below shows how you define the MUT in relation to the fixture holding it in place. So-called ‘de-embedding’ enables you to cover one or both sides of your sample with dielectric backing. De-embedding mathematically eradicates the effect of the backing material, meaning you’re left solely with the electromagnetic properties of the sample. This technique is ideal when the sample isn’t able to stand by itself, or is attached to a substrate.