Source: 3D Printing Media Network news

The copper EBM process could unlock superconducting applications at CERN.

The European Organization for Nuclear Research (CERN) in Switzerland is reportedly interested in exploring GH Induction’s copper 3D printing technology for superconducting applications. The state-of-the-art facility believes it could benefit from the excellent material properties and design freedom afforded by GH Induction’s Cu material and Electron Beam Melting (EBM) process.

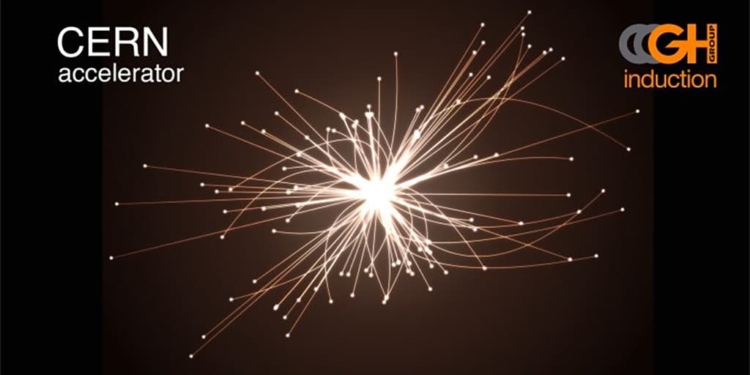

Founded in 1954, CERN is one of the most well recognized research centers in the world, in large part because it operates the largest particle physics laboratory on the planet. It is also well known for housing the Large Hadron Collider (LHC), a powerful particle accelerator that is made up of a 27-km-long ring consisting of over 1,000 superconducting magnets. The massive LHC, which is built 100-meters underground, is used to study particle collisions.

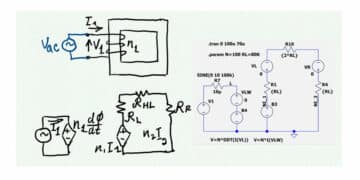

At CERN, GH Induction’s copper 3D printing capabilities could unlock opportunities in next-gen current leads, specifically for the transport of high electrical currents to the cryogenic operating temperatures of the LHC’s superconducting magnets. (The LHC operates at a temperature of -271.25 degrees Celsius!)

Large Hadron Collider (Photo: CERN)

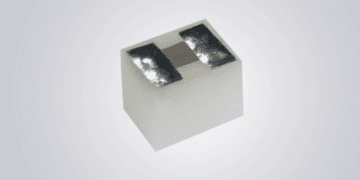

GH Induction has pioneered an approach to 3D printing coils and inductors made of pure copper that relies on an EBM process. Though copper has been notoriously difficult to work with, GH Induction’s technology (as well as a number of other breakthrough processes) are paving the way to increasingly sophisticated copper 3D printing applications.

For instance, the Residual Resistance Ratio (RRR) achieved using GH Induction’s additive Cu process, along with the geometric freedom associated with AM, is making the technology a viable approach for CERN and its superconducting applications.

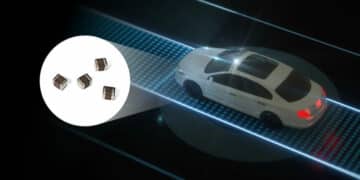

Germany-based GH Induction was the first induction manufacturing company to introduce 3D printed inductors made of 100% pure copper. The unique capability has attracted interest from various industries, including the automotive and tooling sectors. Some of the key advantages of 3D printed copper inductors are an increased service life, lower operating costs and more geometric design freedom—all of which enable new applications.

Copper is a hot topic lately. After many challenges, it has now been proven that it can be 3D printed. EOS has done it and shown it at the last formnext, Trumpf has done it with green laser tech, GKN has done it, JAMPT company in Japan has also done it with EBM technology. Now GH Induction is offering 3D printed copper coils a standard service through its 3Dinductors website.

The group is presenting its exclusive and pioneering technological approach to 3D printing coils and inductors made of pure copper. The technology is based on Electron Beam Melting (EBM), which GH considers to be the only AM method today that works with pure copper rather than alloys. Coil additive manufacturing represents a significant breakthrough in the history of industrial induction heating technology, something that that is already being deployed in automotive and industrial companies and presenting very significant benefits.

Inductors are a critical part of induction heat treatments. They must be replaced due to deterioration from time to time, interrupting production and requiring several man-hours for recalibration. Services, products, and tooling are available to control the induction process, from the development of the heating process up to parameter monitoring to guarantee ideal results. GH’s offering is compatible with any induction manufacturer as EFD, Inductoheat, Ajax Tocco, Seat, SMS Elotherm, etc.

With GH’s 3D inductors, the service life of the inductors can be increased significantly (GH reports up to 4 times longer in some cases). The 3D printed coil spares are geometrically identical, and the designs are optimized for best performance. This means reduced production costs per part and an improvement in treatment that cannot be achieved with any other currently available technology.

The article was edited by EPCI in its content