Source:Composites World news

A need for lightweight energy storage technology is fueling the development of carbon fiber composite materials for car batteries and other electronics.

Driven by an explosion of mobile and portable electronic devices, as well as the proliferation of drones and electric vehicles (EV), the research race is on to develop new lightweight materials for energy storage technology — specifically, materials with longer life and higher weight- and volumetric-based efficiencies.

Carbon and composite materials have been integral components of energy storage systems for several decades, one notable example being graphitic carbon comprising anodes in lithium-ion batteries. The anodes generally consist of a carbon fiber composite manufactured with metal or metal oxides, coupled with polymer coating, barrier layers and some type of cathode, creating an electrical potential that causes electrons to flow through the circuit. Carbon fiber/polymer-matrix composites filled with conductive materials have also been go-to materials for electromagnetic interference (EMI) shielding used in a host of applications including aerospace, automotive and consumer electronics.

One emerging research approach in composites energy storage is minimization of the mass of batteries, fuel cells and capacitors via state-of-the-art materials, with the ultimate goal of increasing overall power densities. “One of the problems you have today is that about 50% of the weight of the battery can go to components that aren’t producing energy,” says Dr. Richard Collins, a senior technology analyst, IDTechEx (London, UK), which conducts independent market research on emerging technologies, including advanced materials.

In battery packs powering electric and hybrid vehicles, for example, one necessary component of a power system’s overall mass is the battery casing. “High-voltage batteries, which can be upwards of 1,000V for performance EVs, generate a lot of radio frequency noise,” says Simon Hiiemae, technical director at automotive heat management specialist Zircotec Group (Abingdon, UK). One way of protecting the sensitive control electronics integrated into EVs, Hiiemae notes, is to place the batteries in a metal box, usually aluminum, which acts as a Farraday cage to absorb electromagnetic field or radio frequency interference, either from the battery itself or surrounding sources; however, this adds substantial weight. Replacing metal with lightweight carbon fiber composites removes the weight, but most composites are transparent to radio frequency noise and do not provide the required level of interference protection.

Zircotec Group has introduced a solution to this technological dilemma: a conductive two-part coating system that can be easily applied to battery casings manufactured from either carbon fiber- or glass fiber-filled composite materials. The coating’s first layer, a thin aluminum alloy bond coat, is applied directly to the composite without any solvents or adhesives, and provides the conductivity required to shield the battery from interference. A second, ceramic layer is applied over the first metallic layer, protecting it from wear and corrosion; additionally, this ceramic layer can be modified to incorporate thermal-barrier protection, shielding the battery from external heat sources. Hiiemae reports that the coating is being tested by a number of vehicle manufacturers; he says the composite battery casing can save up to 4 kg/m2 in weight compared to aluminum.

Multifunctional materials

Also gaining traction in the energy storage industry is a structural laminate that can generate a current or store an electrical charge, an approach that attempts to integrate structural and electrical systems in power-consuming products. Such multi-functional materials, first proposed and explored in research largely targeting military and advanced aerospace applications more than 20 years ago, still face formidable technical challenges on the path to full commercialization. Nevertheless, over the last five to six years, tangible progress in the development of multifunctional materials has been reported on several fronts.

Composite structural supercapacitors (SSCs) show particular potential in the field, in part because of their relatively simple structure. An SSC stores energy via an electrostatic charge accumulation at the electrode/electrolyte interface, which is typically designed as a sandwich structure of two carbon, porous electrodes separated by a membrane and embedded in a liquid electrolyte with high ionic conductivity. Conventional commercial supercapacitors deliver high energy and power densities, long cycle life and reliable operation under a variety of temperatures and conditions. IDTechEx’s Collins says that while SSCs could one day be used to power trains or cars, the earliest commercial SSC application will likely be in unmanned aerial vehicles (UAV) for military use. “SSCs integrated into UAVs could significantly extend range and operational time, a critical performance need,” Collins says. “Also, the first commercial SSCs will be expensive to build, so they will likely be most appropriate for a military type of project.”

An acceleration in the pace of multi-functional materials research is helping to push the technology toward commercialization. For example, an EU-funded project, SORCERER, is providing support for research into lightweight structural energy storage materials for electric and hybrid-electric aircraft. The project is aimed at developing advanced materials and technologies that can be used in both structural batteries and structural supercapacitors.

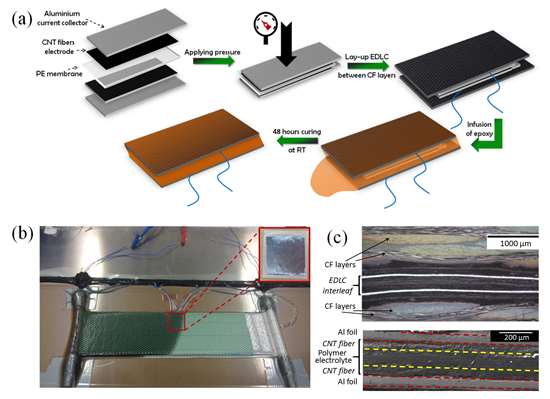

Another project involves the collaboration of a team of researchers at IMDEA Materials Institute (Getafe, Spain) with a number of aerospace partners from EU-funded programs like SORCERER, including Airbus. The team has demonstrated construction of a novel, electric double-layer capacitor (EDLC) manufactured from thin sandwich structures. The structures are interleaves comprising carbon nanotube (CNT) fiber veils and an ionic, liquid-based polymer electrolyte between carbon fiber plies infused with an epoxy resin. Dr. Juan Jose Vilatela, multi-functional nanocomposites group, and one of the participants in the research, says the composites produced in the project are noteworthy for achieving high specific capacitance and power density of 88 mF/g and 30 Wh/kg respectively. This is one to three orders of magnitude higher than the best-performing structural materials. The material also has an energy density of 37.5 Wh/kg, currently one of the highest measured values of structural supercapacitors studied thus far.

Vilatela says CNTs come with the inherent advantage of a 1,000X greater surface area compared to carbon fiber fabrics. CNTs also have high electrochemical stability. To manufacture the EDLC composites, a layup constructed of a thin EDLC interleaf set between eight layers (4+4) of Hexcel (Stamford, CT, US) HexForce high-strength carbon fiber fabric, G0926, was vacuum infused with an epoxy vinyl ester resin, Derakane 8084, supplied by Ashland Chemical (Columbus, OH, US), with full curing occurring in 48 hours at room temperature. The interleaf consists of a sandwich structure comprising, from the middle out, a polymer electrolyte membrane approximately 100-120 microns thick, set between two CNT fiber sheets, both of which are affixed to thin aluminum current-collector plates (Fig. 1). The carbon nanotube fibers were synthesized by a direct spinning method using iron and sulfur catalysts and butane as a carbon source. See article “Aerocomposites: The move to multifunctionality” for more about IMDEA’s CNT fiber.

Fig. 1 Carbon nanotube EDLCs

A team of researchers at IMDEA Materials Institute (Getafe, Spain) has demonstrated construction of a novel, electric double-layer capacitor (EDLC) manufactured from thin sandwich structures. The structures are interleaves made up of carbon nanotube (CNT) fiber veils and an ionic, liquid-based polymer electrolyte between carbon fiber plies infused with an epoxy resin. During manufacture, a layup constructed of a thin EDLC interleaf set between eight layers (4+4) of Hexcel HexForce high-strength carbon fabric is vacuum-infused with an epoxy vinyl ester resin. The final structural supercapacitor (SSC) has a power density about three orders of magnitude higher than other SSCs studied thus far. Source | IMDEA

Prior to being positioned between the outer layers of carbon fiber fabric, a small amount of pressure is applied to the interleaf to execute impregnation of the soft electrolyte membrane into the porous CNT fiber sheets. Samples of the EDLC produced for this study were approximately 4 cm2 — the size of a typical laminate structural beam — although Vilatela saysself-supporting EDLCs, which are made to be used without need for additional structural supports, can be produced in sizes as large as 100 cm2. In-situ electromechanical measurement of the EDLC samples during four-point bending tests show that electrochemical performance is retained up to the point of fracture. This test was a crucial performance validation of the material, given its application as both a structural and energy storage material.

The IMDEA group’s use of unidirectional CNT fabrics to construct the SSC distinguishes the project from similar concurrent work employing a variety of “activated” carbon fiber fabrics as energy-storage materials. One such project, cited in Vilatela’s, et al. paper published in Scientific Reports (February 2018), used an infusion technique to grow a high specific surface area carbon aerogel (CAG) around carbon fiber fabrics. Combined with an ethylene-glycol matrix containing 10% lithium ions, the technique produced a material with a calculated energy density of only 0.84 m Wh kg, which is low compared to the energy density achieved with EDLC comprising CNT fibers. The technique, specifically when using the high specific surface area CAG, produced a composite with a shear modulus of 895 MPa, which is comparable to traditional structural composites. The CNT composites in the IMDEA study, by comparison, had a flexural modulus of 60 GPa and a flexural strength of 153 MPa, values on par with a typical unfilled polyimide and below the strength and stiffness properties required for composites used in primary structural applications.

The results of each of these projects demonstrate, in broad brushstrokes, one of the challenges facing the attempt to develop fully commercial, multifunctional materials suitable for a broad range of applications: namely, it is difficult to build composites with adequate electrical and structural properties.

Collins thinks the current tradeoff between structural and electrical properties will not be a major barrier to the adoption and commercialization of the technology. “I don’t think the fall-off in structural properties in some of these new composite energy-storing materials will be a factor limiting their usefulness,” he says, “because even if you have a slightly worse performing carbon fiber reinforcement, it will still have enough strength and stiffness to be useful in certain applications.” A potentially bigger issue, he believes, is the question of how to design and mechanically integrate solid polymer electrodes and electrically insulating but ionically conductive separators. Additional challenges include cost-effective manufacturing and safety.

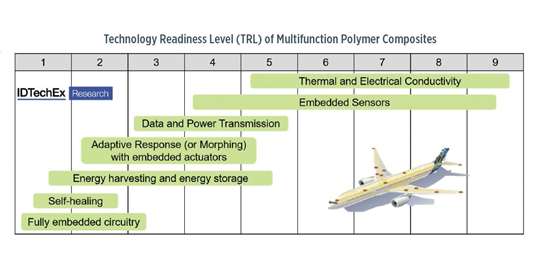

IDTechEx has researched and rated the technological readiness level (TRL) of a variety of multi-functional polymer composites (Fig. 2). The rating system is based on a range of criteria, including whether the research is still mostly academic (which produces a low rating), whether the technology is being prototyped or tested (producing a higher rating), or if the technology is reaching commercialization (highest rating). The data mining reveals that multi-functional materials for energy storage and energy harvesting are, based on IDTechEx’s criteria, still in a relatively early stage of development — slightly ahead of self-healing materials and fully embedded circuitry, but falling behind power transmission and embedded sensors. “When you look at the electrodes of SSCs, for example, one of the challenges is how to improve the surface area appropriately,” Collins notes. “CNTs show promise, but there’s still a ways to go to prove it commercially.”

Fig. 2 Still in early development

IDTechEx’s Technological Readiness Level (TRL) rating gives a technology a lower score if it entails mostly academic research and a higher rating the closer it is to full commercialization. The data mining suggests that multi-functional materials for energy storage and energy harvesting are still in a relatively early stage of development, slightly ahead of self-healing materials and fully embedded circuitry, but lagging data and power transmission and embedded sensors. Source | IDTechEX

Automotive energy technology leading the way

In automotive racing, however, the future in advanced materials energy storage is already here. Cars manufactured for the Formula E circuit, the first fully electric FIA racing series, running since 2014, are powered with advanced, multifunctional composite, 800V structural batteries. The battery technology was developed and manufactured by Williams Advanced Engineering (Grove, UK), the sole supplier of batteries for cars built for the Formula E grid. The typical Formula E car has about 250 Hp (190 kW), can accelerate from 0 to 100 kmh (0 to 62 mph) in 3 seconds, and has a maximum speed of 225 km/h (140 mph). See CW’s November 2018 Focus on Design story, “Pushing EVs forward,” for more information on Williams Advanced Engineering’s structural battery systems for consumer vehicles such as the battery electric FW-EVX.

On another front, Hyundai Motor Group (Seoul, South Korea) is employing hydrogen fuel cell technology supplied by SGL Group (Wiesbaden, Germany) to manufacture its zero-emission car NEXO. The production car caps years of development work and cooperation between the car manufacturer and SGL, during which Hyundai optimized the hydrogen-powered drive train and other components on its iX35 demonstration fuel-cell car. Since commencing production in March 2018, Hyundai has reported selling an average of about 45 units a month, a pace, if it holds, which would culminate with sales of over 500 units in 2018, a new single-year sales record for a hydrogen fuel-cell car.

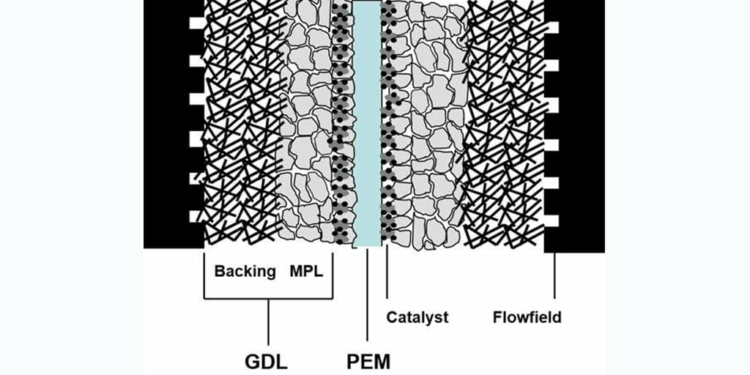

The core of the technology in the NEXO is the SIGRACET fuel cell, a polymer-electrolyte-membrane fuel cell (PEMFC) developed and sold by SGL. The PEMFC generates electrochemical power by converting hydrogen fuel into electricity, with heat and water as the only byproducts. A single PEMFC cell consists of two flowfields, comprising two gas diffusion layers (GDLs) and two carbon-supported noble metal catalyst layers, each separated by a proton exchange membrane (Featured Image Fig. 3). The GDLs are, in turn, a bilayer structure that consists of a macro-porous backing material (carbon fiber paper) and a micro-porous carbon-based layer. The membrane electrode assemblies are built as a layered laminate wherein one GDL acts as the anode and the other GDL layer performs as the cathode. The PEMFC is sandwiched between two bipolar plates (BPP) made from graphite, coated steel or titanium. The BPPs form the structural components of the stack and are designed with channels to accommodate coolant flow and water outlet. Automotive PEMFC systems typically consist of stacks of up to 400 cells with a power output of around 80 to 120 kW.

Composites in energy storage are progressing, but making cleaner, lighter energy sources a large-scale reality will depend on working out the details in advanced technologies such as fuel cells, structural batteries and structural supercapacitors.

featured image fig. 3 Polymer-electrolyte membrane fuel cell

SGL Group’s hydrogen fuel cell technology is used to power Hyundai’s zero-emission car NEXO. Each polymer-electrolyte membrane fuel cell (PEMFC) consists of two flowfields, comprising two gas diffusion layers (GDLs) and two carbon-supported noble metal catalyst layers, each separated by a proton exchange membrane. The GDLs are, in turn, a bilayer structure that consists of a macro-porous backing material (carbon-fiber paper) and a micro-porous carbon-based layer. The membrane electrode assemblies are built as a layered laminate wherein one GDL acts as the anode and the other GDL layer performs as the cathode. Source | SGL Group