- This event has passed.

Optimizing Performance with Panel Mount EMI Filters: Solutions for Effective EMI Control

Optimizing Performance with Panel Mount EMI Filters: Solutions for Effective EMI Control

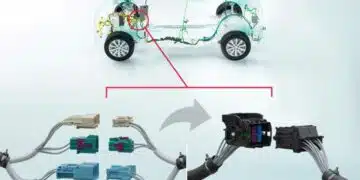

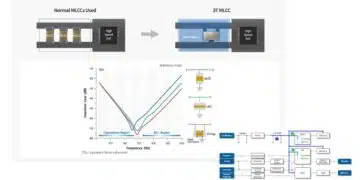

Within electronic design, selecting the right type of filter is just as important as the components on the PCB itself. EMI panel mount filters offer superior performance compared to surface mount filters, particularly when dealing with high frequency applications or environments prone to heat and stress. These filters can provide more effective attenuation of unwanted frequencies, handle higher currents, and ensure long-term durability in mission critical applications. By taking an approach to integrate EMI panel mount filters, circuit designers find that this not only protects sensitive signals, but also safeguards the device’s overall functionality.

An important aspect of this discussion is the distinction between surface mount and panel mount filters. While surface mount filters are smaller and more suitable for compact devices, they often cannot handle the high power or environmental stresses found in certain applications.

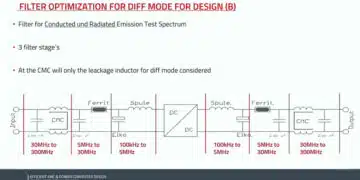

EMI panel mount filters generally provide a wider range of filtering capabilities due to their larger size and ability to incorporate multiple filtering elements, such as inductors and capacitors to form Pi and T networks. These configurations provide tailored filtering solutions that effectively address high-frequency noise issues in high-reliability applications. These design optimizations allow them to manage complex noise profiles, ensure regulatory compliance, and maintain system performance under challenging conditions.

Key Takeaways

- Prevent signal interference and maintain EMC by attenuating high frequencies before they interfere with other components on the PCB layout.

- Improve heat dissipation and durability, ensuring reliable operation in industrial and high reliability environments.

- Reduce PCB space usage by mounting filters externally, allowing more room for critical components.

Speaker

Matthew Walker, Applications Engineer, MLCCs, Knowles