Source: TTI Market Eye article

by Dennis M. Zogbi, Paumanok Inc.

The fastest growth segment of raw material supply to the passive electronic component industry in FY 2019 was that of nickel electrode powder for consumption as multilayered ceramic chip capacitor electrodes.

Nickel supply is one of the only pristine “100% merchant market” value chains left in passive electronic components today, and its positioning outside the captive control of the ceramic capacitor manufacturers offers the unique supply chain a great deal of financial return on investment as the MLCC market expands to satisfy the increasing capacitance signature of key products in multiple end-markets.

Nickel powder and paste production for electrode is dominated by a few small manufacturers who have the unique combination of large scale nickel electrode powder production capabilities, coupled with the ability to create consistently shaped and sized metal powders, and either coat those powders, or produce pastes that easily flowed in a multilayered ceramic process. This article showcases the unique reliance the MLCC industry has on nickel powder and pastes and how the technology has become so advanced that the entire high-tech economy now relies on the capacity and technical prowess of a very small group of vendors in Japan.

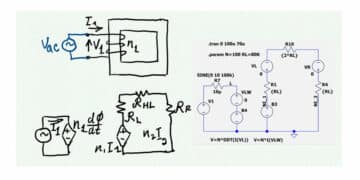

Nickel begins as ore and is mined primarily in Indonesia and the Philippines for consumption in the worldwide steel industry. Its consumption in electronics began almost simultaneously in nickel metal hydride batteries and MLCC electrodes. Its consumption in MLCC electrodes requires the added technical prowess of precipitation of metals into powders. Powder is then converted into inks and pastes by the merchant market or by the electronic component manufacturer in a captive process. Nickel conversion into powder and paste for MLCC electrodes is dominated almost exclusively by Japanese technology houses, with only minor players operated in China, Europe and the Americas (See Figure 1.1 Nickel – An Independent Supply Chain to MLCC).

The following chart (Figure 1.1) illustrates the various stages that nickel is consumed in the production of MLCC-

Figure 1.1: Nickel: An Independent Supply Chain to MLCC, Source: Paumanok Publications, Inc.

MLCC: Market Growth Drives Nickel Electrode Consumption:

The global MLCC market has outperformed the other primary capacitor dielectrics (i.e. tantalum, aluminum and plastic film capacitors) in terms of revenue generation over the past twenty-four months because of a dramatic breakthrough in electrostatic capacitor technology. These breakthroughs involve an increase in the capacitance value per cubic centimeter of dielectric, which in turn allows ceramic capacitors to effectively compete against electrolytic (i.e. tantalum and aluminum) capacitor technologies respectively through the stacking method. In the MLCC stacking method, the ceramic dielectric holds the charge on its available surface area, but the nickel is required to conduct the charge. Therefore- each ceramic dielectric layers requires a matching nickel layer to complete the circuit. In the MLCC, the surface area is increased by stacking up multiple layers of ceramic dielectric materials and alternating nickel electrode materials. This places great emphasis upon the supply chain for nickel to the high-tech economy given the large role MLCC play in providing ubiquitous capacitance in all electronic circuits produced today.

MLCC have dominated the process of providing capacitance for filtering, bypass and decoupling for the past 40 years because they do so cost effectively. Ultimately, the feedstock materials associated with the production of MLCC is lower than the feedstock materials associated with other dielectrics such as tantalum or plastic film but because of the massive size of the global MLCC consumption and its dramatic rate of growth in FY 2019, the associated markets for nickel electrode powders and pastes have surged accordingly.

Nickel Electrode Technology: Key Enabling Electronic Material:

A significant amount of global investment in passive components has gone into the development of very small particle size nickel electrode powders to produce very fine, very thin layers of electrode for the MLCC industry worldwide. Therefore, it is important that the reader understand that nickel electrode powder and paste production is “mission critical” to the future success of volumetric efficiency in electronic components and increasing capacitance in end-products.

Technology in ceramic chip capacitors, especially high capacitance MLCC requires continued investment to remain competitive. This translates into continuing upgrades of nanotechnology platforms for materials, advanced processing steps and variations in sintering and electrode dispersion and printing techniques so that the number of layers per MLCC increases accordingly and within the roadmaps established by portable electronic design engineers.

MLCC Electrode Materials:

Cost savings in electrode materials have been a key factor in MLCC production over the past 25 years. The movement away from palladium + silver to nickel was a significant cost savings initiative that was carefully and methodically initiated to move MLCC away from reliance on precious metals. The firing of MLCC with nickel also allowed for the production of chips with many more layers, and this created an incentive to increase the capacitance value per MLCC and compete against alternative dielectrics. This strategy was extremely successful and added more than $10 billion in value added to the industry over time.

Nickel Electrode materials are most typically purchased in the form of powders by the ceramic capacitor manufacturer from various Japanese, European and American vendors, who in turn then mix the powder into an ink or paste in-house. Some MLCC manufacturers in the specialty segment buy ready-to-use electrode inks from the merchant market to match the MLCC electrode and the dielectric material in what is known in the industry as a “ceramic matching system.”

Electrode materials account for less than 25% of the total raw material costs associated with the production of ceramic capacitors. The electrode markets in nickel remain stable because the market has not been vertically integrated into MLCC ownership and control in the same way as the ceramic dielectric material materials have been gradually merged into the system.

Market growth in nickel electrode powder shipments has been dramatic, and success is based on the ability for the powder supplier to keep in step with the market in terms of developing consistent batches of increasingly smaller, spherical or tetragon shapes powders that do not agglomerate in paste, and can disperse well during the stacking process.

Technology Road Mapping in Nickel Electrode Powders and Pastes:

When Paumanok reviews documents we wrote and comparisons made between nickel electrode particle data by vendor from 2019 with data we collected in 2000 for our study on the nickel electrode powder and paste market (a key milestone in its development), some interesting points can be made that can help with technology road-mapping going forward. The following data is important in helping electronic materials companies move markets forward. By shedding a spotlight on key elements in enabling electronic component technology, especially at the materials level “where the magic happens” it becomes possible to set targets that can accurately be translated into finished components. The variable in the equation is that only those vendors with the long history of commitment to the markets, technologies and opportunities would have such insights to be successful and to maintain consistent share, unless of course they read MarketEYE.

Particle Sizes of Nickel Electrode Powders:

In the year 2000 the leading edge of technology in nickel was well below 1.0 micron in particle size diameter, and the ability to consistently precipitate metal particles far exceeded the capabilities in ceramics. This has never changed. The road-mapping reveals that over the past 20 years that nickel particle size control, coating and dispersion in paste has moved steadily along; still far exceeding that of ceramic dielectric material technology. Also of great interest is that the nickel electrode powder producers have always noted that their technology was more advanced than the ability of the MLCC manufacturers to handle it (Disperse it properly) and this still seems to be the case.

This means with respect to road-mapping that the ceramic dielectric material, which remains captive in many instances, is not as advanced as the nickel electrode materials and processes, and in such instances, where leading edge requirements for volumetric efficiency now exist from 1,000 to 4,700 microfarad, a market that is worth approximately $5 billion in added value to the surface mount capacitor industry, that new methods for stacking 5,000 layers in a 1206 (EIA) case size, with exciting new materials, and semiconductor type, or additive processes cannot be far off!

Source: Paumanok Publications, Inc.