Source: TT Electronics news

Woking, UK, 30 August 2018 – TT Electronics, a global provider of engineered electronics for performance critical applications, has announced the introduction of the WDBR-UL series of ultra-low profile high power resistors.

Developed on the existing WDBR product which itself has been successfully used in the field for over ten years, the new WDBR-UL series’ creepage, clearances and power ratings have been assessed in accordance with the requirements of UL508, easing the compliance burden for UL approved end users.

For circuit designers who need to design UL approved systems containing power resistors in highly compact enclosed assemblies with heatsink-based thermal management, TT Electronics’ WDBR-UL series provides a far lower volume solution than competing encased wirewound products and a faster route to safety certification.

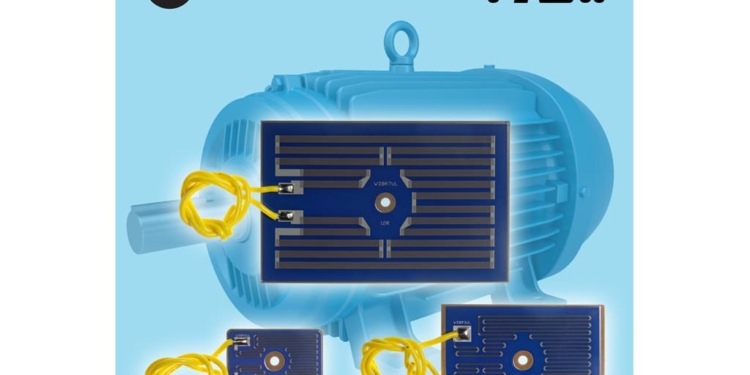

With their ultra-low profile thick-film on steel format, the WDBR-UL resistor series is suitable for, and brings many benefits to, a wide range of applications in the industrial marketplace. These include motor drive inverters, dynamic braking, inrush current limiting, snubber circuits, electronic assembly heater elements, and over-voltage protection in wind turbines.

Versatile, the UL approved resistors are available in nine values from 12R to 150R in five size options and their ultra-low profile design offers a ‘stand height’ thickness of less than 2mm – very desirable for use in modern, compact designs where traditional, bulky wirewound solutions would be unsuitable. The WDBR-UL power resistors offer high isolation from a heatsink even after failsafe overload fusing and feature a very low inductance design. They are available in continuous power ratings up to 1.4kW with up to 7kW continuous peak power dissipation, and they are able to handle single overload power levels up to 13kW.

Offering ease of fitment, they are single fixing heatsink mountable resistors and offer a choice of flying lead or solder terminations. The resistors’ non-flammable, innovative construction comprises a high integrity dielectric layer that is applied to a machined stainless steel substrate. The thick-film conductor and resistor patterns are printed and fired, then protected with a high temperature overglaze. The termination pads are tinned with solder and the optional leads are soldered on. WDBR-UL braking resistors are RoHS compliant.