Source: TTI Market Eye article

by Dennis M. Zogbi, Paumanok Inc.

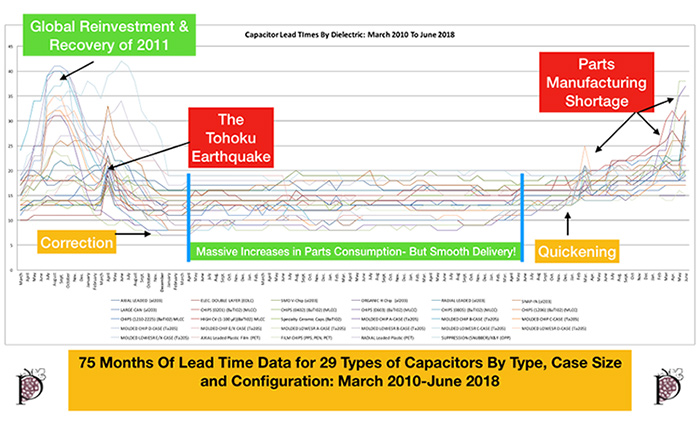

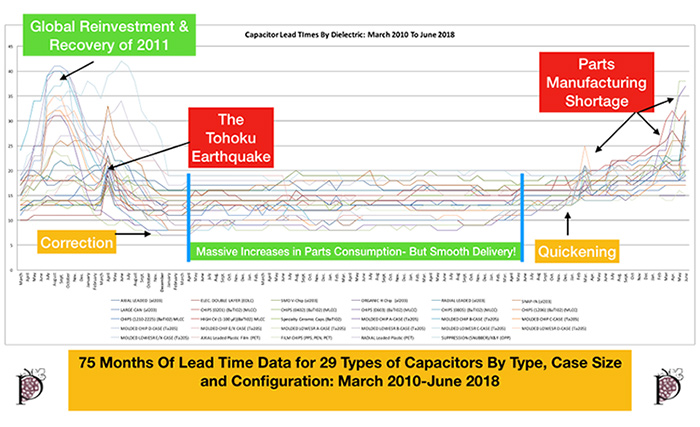

Investing in the Electronic Component Supply Chain Requires a Basic Understanding of Past Cycles. In this Marketeye Article, Paumanok Uses One of Its Many Predictive Analytical Tools to Model Trends in The Passive Electronic Component Industry; Comparing The Current Market Shortages to Disruptions in The Market Cycle in 2011.

Introduction:

The following diagrams illustrate the use of Big Data to model past events in supply chain disruption and to explain how they compare and contrast from prior cycles. The model illustrated is that of the worldwide capacitor industry, which includes for major types, and 30 subcategories that are designated based on raw material, configuration and physical case size.

Figure 1.1 Attached JPEG- 75 Months of Lead Time Data for 29 Types of Capacitors

©2018 Paumanok Publications, Inc. Monthly Market Research Report On Passive Electronic Components Archive Data- [email protected]

Description of the Data Set

The data set shown in this article shows the lead times for capacitors. A lead time is the average amount of time in weeks it takes for a part to be received by a factory and consumed by a customer. The data sets illustrated here show the supply of components at normal “smooth” levels and at times of disruption.

Products Covered

The capacitor big data sets include these 29 individual sub-categories

- Axial Leaded Al203 This is a low volume, high dollar value product line with direct ties to automotive and lighting ballast end-use markets. The number of vendors is limited. The market is very sensitive to demand from automotive electronic subassem,blies where axial leaded designs are preferred for their configuration.

- EDLC Supercapacitors (Carbon) Includes all printed circuit board mounted double layer carbon type supercapacitors in coin cell, cylindrical and packaged component systems. These are low voltage and extremely high-capacitance parts measured in the farad range and used for battery load versus levelling and burst power in specialty circuits. EDLC supercaapcitors can help us determnine the health of the solid state disc drive industry which is where the volume of consumption is most prevalent.

- SMD V-Chip (Al203) This aluminum electrolytic part is the “Vertical Chip” aluminum electrolytic capacitor and offers a combination of high-voltage and high-capacitance. It is not as volumetrically efficient as other types of capacitors and cannot be used in many portable designs as a result. The technology is still important to end markets in consumer audio and video imaging and power supplies. The global flat panel display market is the primary market driver of V-chip aluminum capacitors.

- Organic H-Chip (Al203) This aluminum electrolytic part of a “horizontal” molded chip that fits in the same case size as the larger tantalum chips and is a more cost effective solution. It has smaller economies of scale and a limited number of vendors, but has key customer bases in game console businesses in Asia.

- Radial Leaded (Al203) This is the large volume, mass produced radial leaded aluminum electrolytic capacitors that are consumed in large volumes for consumer audio and video imaging where the combination of high-capacitance and high-voltage is required. This is almost always for smoothing the output filters on power supplies connected to line voltage.

- Snap-In (Al203) This is a large aluminum capacitor product market segment wordwide and includes a category of larger size aluminum capacitors that demonstrate capacitance ranges in the thousands of microfarads and higher voltage handling capabilities. These are also the preferred capacitor for smoothing ouput signals on power suppluies and smooting DC link circuitry in renewable energy systems.

- Large Can (Al203) This is the largest size aluminum capacitors and can be used for heavy industrial applications and power cricuitry, especially for inverters. The products have high-voltage and high-capacitance characeteristics and are mass produced.

- Ceramic 0201 MLCC (Chips (0201 BaTI02) This “multilayered ceramic chip capacitor” MLCC has the physical dimension of 0.02 x 0.01 inches and is extremely small, no bigger than a grain of salt. This product is manufactured from ceramic dielectric materials in a stacked dielecric and electrode configuration and terminated with solderable metal endcaps. This product enables portable technology and is largely consumed in wireless handsets and enables module circuitry. It is used for bypass, decoupling, filtering and is a ubiquitous product line, produced worldwide in the hundreds of billions of pieces.

- Ceramic 0402 MLCC (Chips (0402 BaTI02) This “multilayered ceramic chip capacitor” MLCC has the physical dimension of 0.04 x 0.03 inches and is extremely small. This product is manufactured from ceramic dielectric materials in a stacked dielectric and electrode configuration and terminated with solderable metal endcaps. This product enables portable technology and is largely consumed in wireless handsets and enables module circuitry. It is used for bypass, decoupling, filtering and is a ubiquitous product line, produced worldwide in the hundreds of billions of pieces. It is the largest mass produced part in the world.

- Ceramic 0603 MLCC (Chips (0603 BaTI02) This “multilayered ceramic chip capacitor” MLCC has the physical dimension of 0.06 x 0.03 inches and is very small. This product is manufactured from ceramic dielectric materials in a stacked dielectric and electrode configuration and terminated with solderable metal endcaps. This product is used in many circuits, but is generally too large for today’s modern handsets. It is used for bypass, decoupling, filtering and is a ubiquitous product line, produced worldwide in the hundreds of billions of pieces. It would have end-markets in automotive, industrial and computer.

- Ceramic 0805 MLCC (Chips (0805 BaTI02) This “multilayered ceramic chip capacitor” MLCC has the physical dimension of 0.08 x 0.05 inches and is very small. This product is manufactured from ceramic dielectric materials in a stacked dielecric and electrode configuration and terminated with solderable metal endcaps. It is used for bypass, decoupling, filtering and is a ubiquitous product line, produced worldwide in the hundreds of billions of pieces. It would have end-markets in automotive, industrial and computer.

- Ceramic 1206 MLCC (Chips (1206 BaTI02) This “multilayered ceramic chip capacitor” MLCC has the physical dimension of 0.12 x 0.06 inches and is very small. This product is manufactured from ceramic dielectric materials in a stacked dielectric and electrode configuration and terminated with solderable metal endcaps. It is used for bypass, decoupling, filtering and is a ubiquitous product line, produced worldwide in the tens of billions of pieces. It would have end-markets in automotive and industrial.

- Ceramic 1210-1225 MLCC (Chips (1210-1225 BaTI02) This “multilayered ceramic chip capacitor” range of MLCC has the physical dimension of 0.12 x 0.10 to 0.12 to 1225 inches. This product range is manufactured from ceramic dielectric materials in a stacked dielectric and electrode configuration and terminated with solderable metal endcaps. It is used for bypass, decoupling, filtering and is a smaller product line used for value added and application specific end-marklets, produced worldwide in the hundreds of millions of pieces. It would have end-markets in defense and specialty markets.

- Ceramic High-CV MLCC (Chips all Sizes BaTI02 In Hydrothermal, alk-oxide or sol-gel) This “multilayered ceramic chip capacitor” range of MLCC is just the high capacitance MLCC from one microfarad to 100+ microfarad (now includes 220, 330, 470, 680 and 1000 microfarad parts). This product range is manufactured from ceramic dielectric materials in a stacked dielectric and electrode configuration and terminated with solderable metal endcaps. In this category only, all electrodes are nickel and all terminations are copper. It is used for bypass, decoupling, filtering in all product lines and is the enabeling technology for portability in handsets and computer tablets.

- Ceramic Specialty Capacitors This is a basket category of all ceramic capacitors in chip, axial and radial leaded configurations consumed in high-temperature, high-voltage and high-frequency circuits. This category incliudes product lines consumed in value-adedd and application specific end-use markets in infrastructure, defense, oil and gas and medical electronics segments and would inlucde safety capacitors and tip and ring capacitors.

- Tantalum, Molded Chip A Case (Manganese Cathode) ultra-small, high capacitance molded chip “A” Case design consumed in portable electronics. Major end markets include wireless handsets, computer tablets, high end consumer AV and hearing aids. The dielectric material is tantalum. The cathode material is manganese.

- Tantalum, Molded Chip B Case (Manganese Cathode) ultra-small, high capacitance molded chip “B” Case design consumed in portable electronics. Major end markets include portable computers, automotive and cameras. The dielectric material is tantalum. The cathode material is manganese.

- Tantalum, Molded Chip C Case (Manganese Cathode) ultra-small, high capacitance “C” Case molded chip design consumed in all electronics. Major end markets include portable and desktop and server computers, game consoles and automotive. The dielectric material is tantalum. The cathode material is manganese.

- Tantalum, Molded Chip D Case (Manganese Cathode) ultra-small, high capacitance “D” Case molded chip design consumed in computer, infrastructure, industrial and automotive electronics. The dielectric material is tantalum. The cathode material is manganese. D Case size tantalum chips give us an excellent window into the overall global health of the industrial high tech economy.

- Tantalum, Molded Chip E/X Case (Manganese Cathode) ultra-small, high capacitance “E/X” Case molded chip design consumed in computer, infrastructure, industrial and automotive electronics. The dielectric material is tantalum. The cathode material is manganese.

- Tantalum, Molded Chip A Case (Polymer Cathode) ultra-small, high capacitance molded chip “A” Case design consumed in portable electronics. Major end markets include wireless handsets, computer tablets, high end consumer AV and hearing aids. The dielectric material is tantalum. The cathode material is conductive polymer such as polythiophene or polypyrole to lower the equivalent series resistance (ESR).

- Tantalum, Molded Chip B Case (Polymer Cathode) ultra-small, high capacitance molded chip “B” Case design consumed in portable electronics. Major end markets include portable computers, automotive and cameras. The dielectric material is tantalum. The cathode material is conductive polymer such as polythiophene or polypyrole to lower the equivalent series resistance (ESR).

- Tantalum, Molded Chip C Case (Polymer Cathode) ultra-small, high capacitance “C” Case molded chip design consumed in all electronics. Major end markets include portable and desktop and server computers, game consoles and automotive. The dielectric material is tantalum. The cathode material is conductive polymer such as polythiophene or polypyrole to lower the equivalent series resistance (ESR).

- Tantalum, Molded Chip D Case (Polymer Cathode) ultra-small, high capacitance “D” Case molded chip design consumed in computer, infrastructure, industrial and automotive electronics. The dielectric material is tantalum. The cathode material is conductive polymer such as polythiophene or polypyrrole to lower the equivalent series resistance (ESR). D Case size tantalum chips give us an excellent window into the overall global health of the industrial high tech economy.

- Tantalum, Molded Chip E/X Case (Polymer Cathode) ultra-small, high capacitance “E/X” Case molded chip design consumed in computer, infrastructure, industrial and automotive electronics. The dielectric material is tantalum. The cathode material is manganese.

- Plastic Film; Axial Leaded Plastic Film (Polyethylene Terapthalate Plastic Film Dielectric) is an axial leaded plastic fiolm capacitor that has direct ties to the nautomotive and lighting markets. The reader should note that this channel has similarities to the axial leaded aluminum capacitor markets and should be veiwed collectively.

- Plastic Film: Film Chips (PPS, PEN and PET Films) is a basket category that includes all the surface mount sub-categories for the plastic film dielectric. These currently inlcude the polyphenylene sulfide chip, the polyethylene naphthalate chip and the polyethylene terapthalate chip. These film chip capacitors are used for backlighting in flat panel displays and are also preferred in certain types of power supplies and DC/DC converters.

- Plastic Film: Radial Leaded Plastic Film (PET Plastic Film) is a capacitor configuration that has market and construction similarities with the radial leaded aluminum capacitors. This represents a large market for plastic film c apacitor producers and inlcudes customers in home theatre electronics, lighting ballasts and power supplies.

- Plastic Film: Suppression Film (Snubber/X&Y) is a polypropylene film capacitor that is used in line voltage, or electrical type AC circuits. It tells us the health of the smoke detector, alarm system, set-top box, and industrial power end-use market segments. Power film capacitors are used primarily for smoothing input cricuits on power supplies, but are also used for degaussing and pulse power.

Using Big Data Sets to Model Past Cycles

In past MarketEYE articles I have noted how I believe that this shortage in 2018 is more closely resembling events in 2000 rather than in 2011, however, to model this contrast, I wanted to illustrate how certain analytical tools employed by Paumanok register the patterns the market displays in times of shortages and how this expresses itself in other predictive ways, with the most obvious and salient impact on prices of public traded stocks of passive component companies.

In Figure 1.1: “75 Months of Capacitor Lead Time Data” the data shows the detailed lead time signatures of the 29 capacitor sub-types described above between March 2010 and June 2018- here are the comparative findings.

March of 2010 Through January of 2012 – In the figure the data clearly shows how these 29 electronic components responded to the global economic relief packages that were put in place by the United States, Western Europe, Japan and China in response to the global economic downturn of 2009. The reader should note that the nature of this major global infusion of capital was in many respects technological, with clear funding in the fields of infrastructure for communications and transportation that ultimately impacted medical, defense, test and measurement, automotive and space related industries. Please note how most of the 29 capacitor products tracked by the Paumanok system demonstrated increased lead times and increased market demand during this time period, but not all of them did. The subsequent event in March thourgh June of 2011 modelled a panic buying incident.

March of 2011 Through June of 2012 – In the figure the data shows the result of the panic buying that happened immediatley following the earthquake off the coast of Japan in March of 2011. The assessment was made that critical raw material factories for MLCC and aluminum capacitors, as well as primary factories for tantalum were significantly damaged and would have their ouput halted until recovery. The reader will also note how the market demand and lead times impacted all passive components almost equally because in a panic buying environment the customer tends to buy all he can because his information is limited but his budget has flexibility.

July 2012 Through April of 2013 – The subsequent capacity additions from the events of March 2010 through June of 2012, mainfested inself in a “reversal of fortune” in July of 2012 through April of 2013, and this impacted the lead times of all capacitor components equally.

May of 2013 Through May of 2017 – This time period reflects the markets in parity and operating smoothly, with very little or no major changes in lead times for a full 48 months. During this time period the number of capacitors consumed in the world increased, as did the amount of capacitance required for many types of products, especially handsets and automobiles.

June of 2016 Through June of 2017 – This time period is interesting in retrospect as it illustrates a tightening (quickening) of the lead times for many of the “faster to market” products and is an economic bellweather that will be used in future models to warn of pending shortages in the capacitor supply chain.

July of 2017 Through June of 2018 Parts Shortages – The model begins to take on an appearance of a shortage beginning in June of 2017 and now attempting to reach similar heights of the past shortage in 2011. Such patterning can be used to create models that suggest when the market will cycle through.

Figure 1.1 Attached JPEG- 75 Months of Lead Time Data for 29 Types of Capacitors

©2018 Paumanok Publications, Inc. Monthly Market Research Report On Passive Electronic Components Archive Data- [email protected]

Source: PaumanokPublications, Inc.