Connector Materials and Processes

Contact Finish Electroplating

The majority of connector contact finishes are applied by continuous electroplating of reels of stamped and formed contacts with tin,...

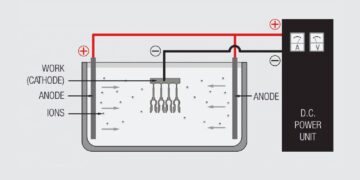

Read moreDetailsElectroplating Basics

Electroplating, or electrodeposition, in connector technology refers to the plating of a material, selected for the properties discussed in Chapter...

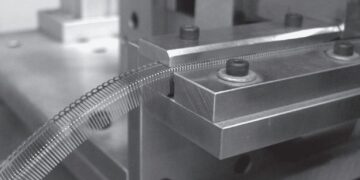

Read moreDetailsReel-to-Reel Strip Plating

The following discussion provides a basic overview of the stages of electrodeposition during a reel-to-reel strip plating process. The manufacturing...

Read moreDetailsContact Finish Electroplating Miscellaneous

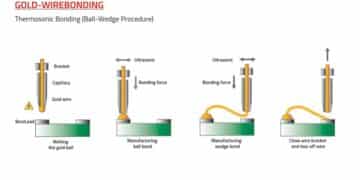

Not all connector contacts are reel-to-reel plated. There are two batch plating processes and two non-electrolytic practices worthy of a...

Read moreDetailsCopper Alloy Metallurgy and Processing

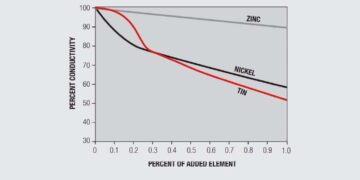

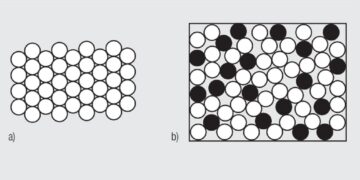

The majority of connector contacts are manufactured from copper alloys due to the combination of high electrical conductivity and good...

Read moreDetailsCopper Strip Processing

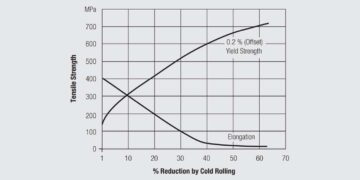

The vast majority of connector contacts are stamped and formed from copper alloy strip. This discussion of copper strip processing...

Read moreDetailsConnector Contact Stamping and Forming

Stamping process is used to convert blank metal strip into contacts or shields by cutting and forming it. The press...

Read moreDetailsCopper Alloys

Copper alloys are commonly divided into several categories depending on the alloying element(s) and the amount of alloying. The dominant...

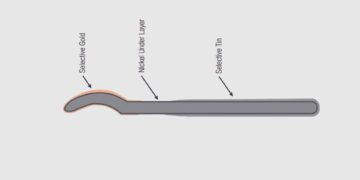

Read moreDetailsHow Much Gold is Needed for Connector Plating

This blog written by Samtec discusses how much gold is needed to specify on the connector pins plating. Gold Plating...

Read moreDetailsConnector Function

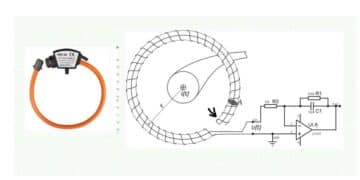

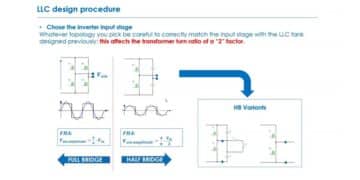

With this basic introduction to connectors in hand, consider now a more detailed introduction to connectors and the components of...

Read moreDetails