Source: VSparticle news

Just as Google’s Verily announces it will stop its smart lens development project, the Dutch startup releases a promising sensor printing technology that can finally bring a successful smart contact lens to market.

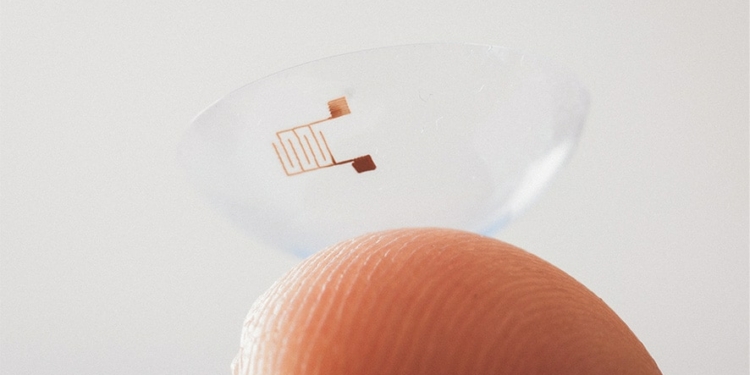

Delft, The Netherlands, November 26, 2018 – VSPARTICLE, today announced its low-cost technology to print nanostructured materials that will finally enable applications such as smart contact lenses to succeed. The nanotech company has developed an additive manufacturing technology that can be used for numerous applications, such as producing real-time medical sensors (glucose sensing, bio-marker sensing, etc.), as well as, accurate gas sensors.

VSPARTICLE is able to produce extremely sensitive materials, built up from pure metals and oxides, which can be printed on flexible substrates, such as polymers. Its technology provides the important accuracy required for glucose testing, as one example, and can be reproduced quickly. The main focus for this technology is sensors, semiconductors, micro-batteries, micro-LED’s and bioelectronics. Google (Alphabet, Verily) announced in a blog post last week that it has stopped its glucose measuring smart lens project in part because ‘after four years of research detecting blood sugar in tears is a massive — and potentially insurmountable — technical and scientific undertaking.’

“Being able to print on curved, flexible surfaces is one of the biggest challenges for medical sensors, next to bio-compatibility of sensor material. With the lens we are able to solve both problems as we have demonstrated by printing a gold sensor on an ordinary contact lens,” says Vincent Laban, CFO for VSPARTICLE.

The university spinout, VSPARTICLE, makes machines that produce nanoparticles in the crucially important right amounts and sizes and does it with the push of a button. These particles serve as the foundation for new materials and nano-enabled products. With the launch of its 3D Nanoprinter next year, it will make the printing of materials with nanoparticle properties just as simple and effective.

“The technology that VSP has developed has the potential to literally change the world. Every investor is looking for that special company that can actually have a real impact. VSPARTICLE is that company,” says Keesjan Cordia, investor with Invaco Management, which seed funded the company in 2017.

Science Fiction?

The potential for VSPARTICLE’s smart contact lens tech is extensive outside of its medical uses. Future scenarios already in development by companies and institutes such as IMEC, incorporate electronics and LEDs on contact lenses, or even involve recording video or taking photos using voluntary blinks to control the images. VSPARTCLE’s technology would play a key role in making such applications viable.

Dutch Roots

The company was spun out of leading Dutch university, TU Delft, by professor Andreas Schmidt-Ott, scientist Tobias Pfeiffer and former student, Van Vugt in 2014. The entrepreneurs spent the first two years, improving and simplifying the technology to make it easy enough to get results with the push of a button. Many believe the potential for VSPARTICLE’s technology is enormous.

About the Company

VSPARTICLE is the Dutch nanotechnology company that provides research and industry with the tools to manufacture nanoparticles and nanostructured materials. Since 2014, the company helps scientists and industry leaders to drastically reduce the development time of new materials and products, by making it as easy as pushing a button. VSPARTICLE is a privately funded company by investors who see untapped potential in the company, especially for applications in semiconductors, sensors, catalysis, healthcare, batteries, fuel cells and pv. The company currently employs 20 people at its headquarters in Delft, and has an international distribution network in the USA, Europe and Asia.